Deciding between screen printing and heat transfer really comes down to what your specific project needs. For big, simple-color bulk orders, screen printing is the undisputed champion. It’s incredibly durable, and the per-item cost drops way down at scale. On the other hand, modern heat transfer methods like DTF (Direct to Film) are perfect for small batches, full-color photorealistic images, and super detailed designs with a quick turnaround.

Choosing Your T-Shirt Printing Method: A Quick Comparison

When you're ready to bring a t-shirt design to life, the printing method you choose impacts everything from the final look and feel to your budget. Screen printing and heat transfer are two of the most popular techniques out there, but they serve very different purposes and produce distinct results.

Getting a handle on these core differences is the first step toward making a smart, cost-effective decision for your business or creative project.

The Case for Screen Printing

Screen printing has been the industry standard for high-volume jobs for ages. The process involves pushing ink through a mesh stencil directly onto the fabric, creating a durable and vibrant print that literally becomes part of the garment. It’s no surprise it holds a commanding 56% market share in the global custom t-shirt printing industry, making it the go-to for bulk orders like company uniforms or event merchandise. For a deeper dive, you can discover more insights about the custom t-shirt market and its trends.

The Flexibility of Heat Transfer

Heat transfer methods, especially modern DTF transfers, offer incredible flexibility. Instead of screens, these methods use heat and pressure to apply a pre-printed design onto the shirt. This digital-first approach is ideal for complex, multi-color graphics and smaller, customized orders—all without the hefty setup costs that come with screen printing.

Key Takeaway: Your choice isn't just about the technology; it's a strategic decision based on order size, design complexity, and desired turnaround time. Screen printing wins on volume, while heat transfer excels in versatility.

To make things even clearer, let's look at the most critical factors side-by-side.

Screen Printing vs Heat Transfer At a Glance

Here’s a quick breakdown of how these two methods stack up against each other, helping you pinpoint the best fit for your next project.

| Factor | Screen Printing | Heat Transfer (incl. DTF) |

|---|---|---|

| Ideal Order Size | Large batches (50+ pieces) | Small to medium batches (1-500+ pieces) |

| Durability | Extremely high; ink bonds with fabric | Very high with DTF; sits on fabric |

| Color Complexity | Best for simple, spot colors (1-4) | Unlimited colors, gradients, and photos |

| Cost Per Print | Low for bulk orders, high for small runs | Consistent cost, great for small orders |

| Setup Time | High (screen creation per color) | Minimal (digital file preparation) |

| Best For | Uniforms, band merch, promotional gear | On-demand shops, custom gifts, detailed art |

This table lays out the core trade-offs. If you’re running a large batch of shirts with a simple logo, screen printing is your workhorse. But for a small shop needing to print detailed, full-color designs on demand, the speed and versatility of DTF heat transfers are hard to beat.

Comparing Quality, Finish, Color, and Durability

When you get right down to it, the choice between screen printing and heat transfer often comes down to the final product. How does it look? How does it feel? These are the differences that your customers will notice and what ultimately shapes the perceived value of your custom apparel.

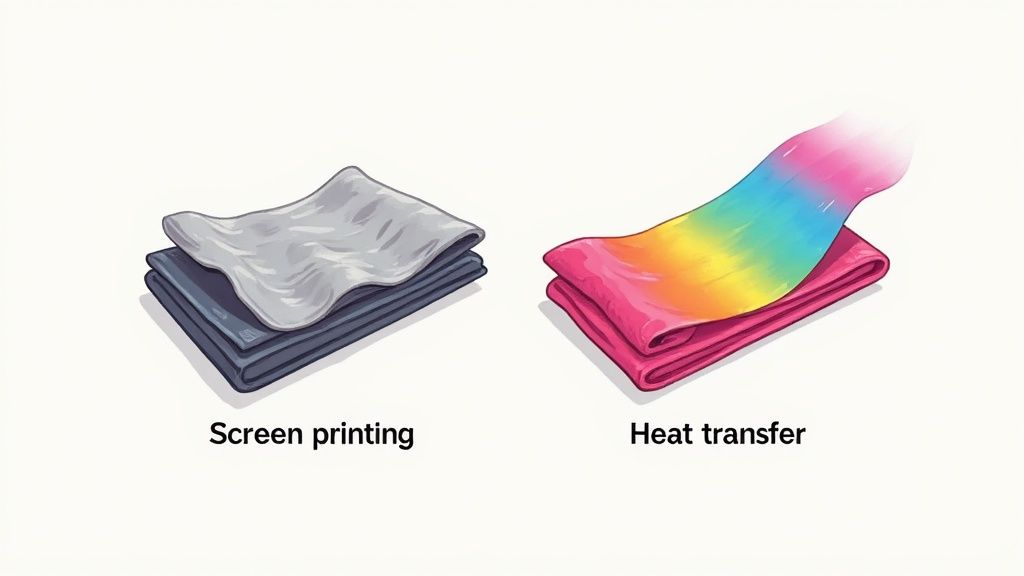

The first thing you’ll notice is the tactile feel, or what we in the biz call the "hand." A screen-printed design feels like it's a part of the shirt. That’s because the plastisol ink is pushed into the fabric's fibers before being cured, creating a finish that’s soft, breathable, and moves right along with the garment. It’s that classic, professional feel everyone recognizes.

On the other hand, a heat transfer design sits on top of the fabric. It’s a distinct layer applied with a heat press. Now, if you're thinking of the old, stiff heat transfer vinyl (HTV) that felt like a plastic shield on your chest, think again. Modern Direct to Film (DTF) transfers are incredibly thin and flexible, offering a much softer hand that gives screen printing a serious run for its money.

Vibrancy and Color Reproduction

This is where the two methods really start to show their differences. Screen printing is the undisputed champion of bright, opaque colors. Since each color is its own thick layer of ink, the result is a bold, saturated look that really pops, especially on dark shirts. This spot color process is perfect for matching brand logos with precision.

But that strength is also its biggest weakness. Every single color needs its own screen, which ramps up the complexity and cost pretty fast. Trying to reproduce a photograph or a design with smooth gradients gets tricky and expensive. It usually requires techniques like halftones, which use tiny dots to fake a gradient effect. To see how that works, you can check out our guide on using halftones in screen printing for complex designs.

This is exactly where heat transfers, especially DTF, step in to save the day. Because the printing process is fully digital, DTF can handle an unlimited number of colors, tiny details, and photorealistic images with perfect accuracy. It makes complex artwork, photography, and smooth color blends not just possible, but easy.

Key Insight: Screen printing is your go-to for unmatched vibrancy on simple, bold designs with just a few colors. But for photos, gradients, and unlimited color palettes, DTF heat transfers deliver superior detail and flexibility without adding setup costs for each new color.

Durability and Washability Examined

Let’s talk longevity—one of the most critical points in the screen printing vs. heat transfer debate. Screen printing has a legendary reputation for being tough as nails. The ink literally becomes one with the fabric, so a well-cured print can easily outlive the shirt itself without cracking or fading.

Historically, this is where heat transfers got a bad rap. Older methods like transfer paper or cheap vinyl were notorious for cracking, peeling, and fading away after only a handful of washes. This left people thinking of heat transfers as a lower-quality choice for promotional giveaways or one-time events.

But that’s old news. The game completely changed with DTF transfers. These modern transfers are built for incredible durability, with high-quality DTF prints tested to handle 100+ wash cycles without any major breakdown. The ink film is flexible, so it stretches with the fabric instead of cracking under pressure. When applied correctly, a DTF transfer offers washability and longevity that absolutely rivals traditional screen printing.

Here’s a quick breakdown of how they stack up on durability:

-

Screen Printing:

- Ink gets absorbed directly into the fabric fibers.

- Extremely resistant to cracking and fading over time.

- Stands up to high-temperature washes and rough conditions.

-

Modern DTF Heat Transfer:

- A flexible ink layer bonds to the fabric’s surface.

- Highly resistant to cracking because of its elasticity.

- Keeps its vibrant color through dozens and dozens of washes.

Ultimately, there’s no single “best” choice—it all depends on the job. For a simple one-color logo on work uniforms that are going to take a beating, screen printing is a trusted workhorse. But for a growing brand that needs to pump out vibrant, multi-color designs on demand, the durability and quality of modern DTF transfers make them an equally powerful and reliable option. This is exactly why so many shops now use both methods to cover all their bases.

Analyzing the Economics: Cost Per Print and Scalability

When it comes down to choosing between screen printing and heat transfer, the conversation almost always lands on the numbers. The look and feel of the print matter, of course, but the cost per print and how each method scales will ultimately decide which one fits your business. Each has a totally different financial model with its own set of trade-offs.

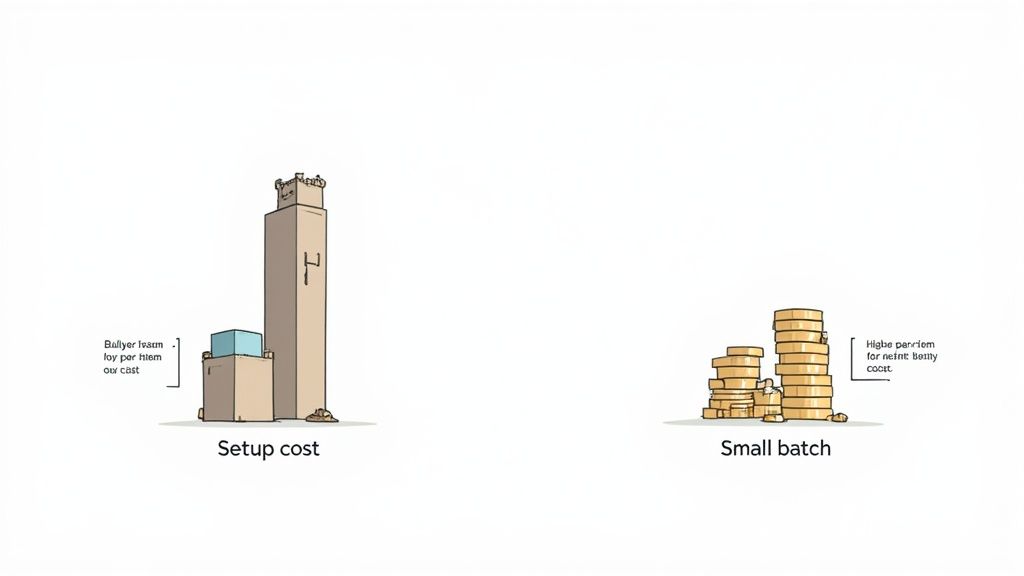

Screen printing is a volume game, pure and simple. The upfront investment in time and materials is significant. You have to create a separate screen for every single color in a design—that means coating it with emulsion, exposing it, and getting it perfectly aligned on the press. This setup process makes printing just one or two shirts incredibly expensive.

But once you're set up, the cost for each additional shirt drops dramatically. That’s why screen printing has always been the king for big jobs like corporate apparel, band merch tours, and event giveaways. The setup cost gets spread out over hundreds or even thousands of shirts, making it the most cost-effective option for bulk production.

Unpacking Heat Transfer Costs

Heat transfer, especially modern Direct to Film (DTF), flips that economic model on its head. There are practically zero setup costs tied to the design itself. Whether your artwork has one color or a photorealistic gradient with a hundred, the prep work is the same: you just send a digital file to the printer.

This makes heat transfer a perfect match for the on-demand market, small businesses, and anyone who needs flexibility. The cost per print stays pretty much the same whether you’re making one shirt or fifty. This opens the door to personalization, easy prototyping, and filling small orders without the huge financial risk of screen printing’s minimums.

While the raw material cost for a single heat transfer might be higher than a screen print in a massive run, its true value is in its agility and low barrier to entry. For entrepreneurs weighing the pros and cons, understanding different strategies for print-on-demand businesses is key to seeing how cost per print impacts profitability.

Economic Snapshot: Screen printing is built on economies of scale—high setup costs are justified by a low per-unit price on large orders. Heat transfer offers a stable, predictable cost per shirt, making it ideal for on-demand production and smaller, more varied batches.

The DTF Advantage with Gang Sheets

Modern DTF transfers have a secret weapon that helps bridge the economic gap between these two methods: the gang sheet. A gang sheet is one large sheet of transfer film where you print multiple different designs all at once. For cost efficiency, this is a total game-changer.

Instead of paying for each design individually, you pay for the total area of the film. This lets you cram various logos, graphics, and full-color images into a single print job, slashing the cost of each individual transfer. This is where a tool like our Auto-build gang sheet builder becomes so valuable.

Our builder takes the guesswork out of it, letting you upload multiple designs and automatically arranging them to use every last square inch of the sheet. You get the cost-effectiveness of a bigger print run but with the flexibility to produce a ton of different designs. It makes small-to-medium batch printing far more profitable.

Here’s how the numbers break down in the real world:

- Screen Printing: Still the champ for huge orders where cost is the only thing that matters. Screen printing holds a 56% revenue share globally, winning on high-volume jobs where costs can fall to just $2-$4 per shirt on orders of 1,000+.

- Heat Transfer: Wins on flexibility and detail. The heat transfer printing market was valued at $4.21 billion in 2024, powered by its ability to handle photorealistic art and custom orders, where the per-shirt cost might be around $5-$8.

By using a gang sheet, a small brand can produce 20 different full-color designs for a tiny fraction of what it would cost to screen print each one. This kind of scalability lets a business expand its product line without the massive capital investment that traditional methods demand. It’s the on-demand nature of heat transfer, but with a cost structure that gets much closer to bulk printing.

Production Speed and Turnaround Time: Getting Orders Out the Door

In the world of custom apparel, speed matters. A client with a rush order or a sudden spike in demand for a particular design means you need a printing method that can keep up. When you look at how fast you can move from a digital file to a finished shirt, the difference between screen printing and heat transfer becomes crystal clear.

Screen printing is a craft, and like any craft, it requires a significant amount of prep work. This is where most of the time is spent. You have to create a separate screen for every single color in the design, coat it, expose it, wash it out, and then line everything up perfectly on the press. For a design with three or four colors, you could easily spend hours on setup before the first shirt ever gets printed.

This front-loaded labor makes screen printing a terrible choice for one-off jobs or small, personalized orders. The time investment only makes sense when you can spread that setup cost across hundreds, or even thousands, of identical prints.

The Digital Advantage of Heat Transfer

Heat transfer, and modern DTF in particular, operates on a completely different clock. Because it's a digital process, it completely skips the manual, time-consuming setup that bogs down screen printing. There are no screens to prep, no messy inks to mix, and no complicated color separations to worry about.

The workflow is beautifully simple: send a digital file to the printer, print the transfer, and it's ready to press. From the moment you get the file to holding a finished shirt, the whole thing can take just a few minutes. This incredible speed makes heat transfer the undisputed winner for same-day service, on-demand printing, and personalized orders. All you need to get started is a good press. You can even explore different options for a heat press machine for t-shirt printing to see what fits your space and budget.

Key Difference: Screen printing's speed is in its raw output after a long and tedious setup. Heat transfer's speed is in its immediate readiness, making it perfect for quick turnarounds on any size order.

How Gang Sheets Maximize Your Speed

For any print shop, maximizing output is the name of the game. This is where DTF transfers really pull ahead, especially when you use smart tools to help you. The ability to print multiple, completely different designs on a single large sheet—known as a gang sheet—is a massive time-saver. The only downside is that arranging all those designs by hand to use every inch of film can be a real drag.

That’s exactly the problem our Auto-build gang sheet builder was designed to solve. Just upload your designs, and the tool intelligently and automatically arranges them to fit perfectly on the sheet, killing waste and eliminating the time you’d spend manually dragging and dropping files. This automated process takes you from a folder of digital files to a press-ready sheet in seconds.

This level of efficiency allows shops to knock out aggressive deadlines without the multi-hour setup that screen printing forces on you. It's a powerful way to boost your production capacity and profitability, letting you turn around diverse, multi-design orders with the speed of a single job.

Choosing the Right Method for Your Project

Making the final call between screen printing and heat transfer is where the theory hits the production floor. It’s not just about specs on a page; it’s about matching the method to your project goals, your audience, and your business model. The "best" choice really depends on the job in front of you.

For big jobs, screen printing is still the undisputed champ. Think massive corporate events, promotional giveaways, or a band's tour merch. When you need hundreds (or thousands) of identical, durable shirts, your main goal is getting the lowest possible cost per piece, and that’s where screen printing shines.

Heat transfer, on the other hand, is built for speed and customization. It’s the engine powering countless Etsy shops selling personalized gifts, the go-to for sports teams needing custom names and numbers on jerseys, and the perfect tool for designers creating one-off prototypes. The low setup cost makes small batches not just possible, but incredibly profitable.

Real-World Scenarios When to Use Each Method

Let's walk through a few common situations to see which method really pulls ahead. These examples should make it crystal clear when to reach for screen printing, heat transfer vinyl (HTV), or modern DTF transfers.

-

Large Corporate Order (

500+Shirts): A company needs 500 T-shirts with its two-color logo for a trade show. Screen printing is the obvious winner. The high volume swallows the initial setup costs, driving the price per shirt way down while guaranteeing brand color accuracy and serious durability. -

Local Sports Team (

25Jerseys): A youth soccer team needs jerseys, each with a unique name and number. Heat transfer is the only practical choice. Trying to screen print this level of personalization would be outrageously expensive and take forever. -

Online T-Shirt Store (On-Demand): A designer launches an online shop with 30 different, complex, full-color designs. DTF heat transfers are the perfect solution. With no minimum orders, they can print designs only when they sell, killing inventory risk and allowing for a virtually unlimited product catalog. This is made even more cost-effective by using our Auto-build gang sheet builder to print multiple designs at once.

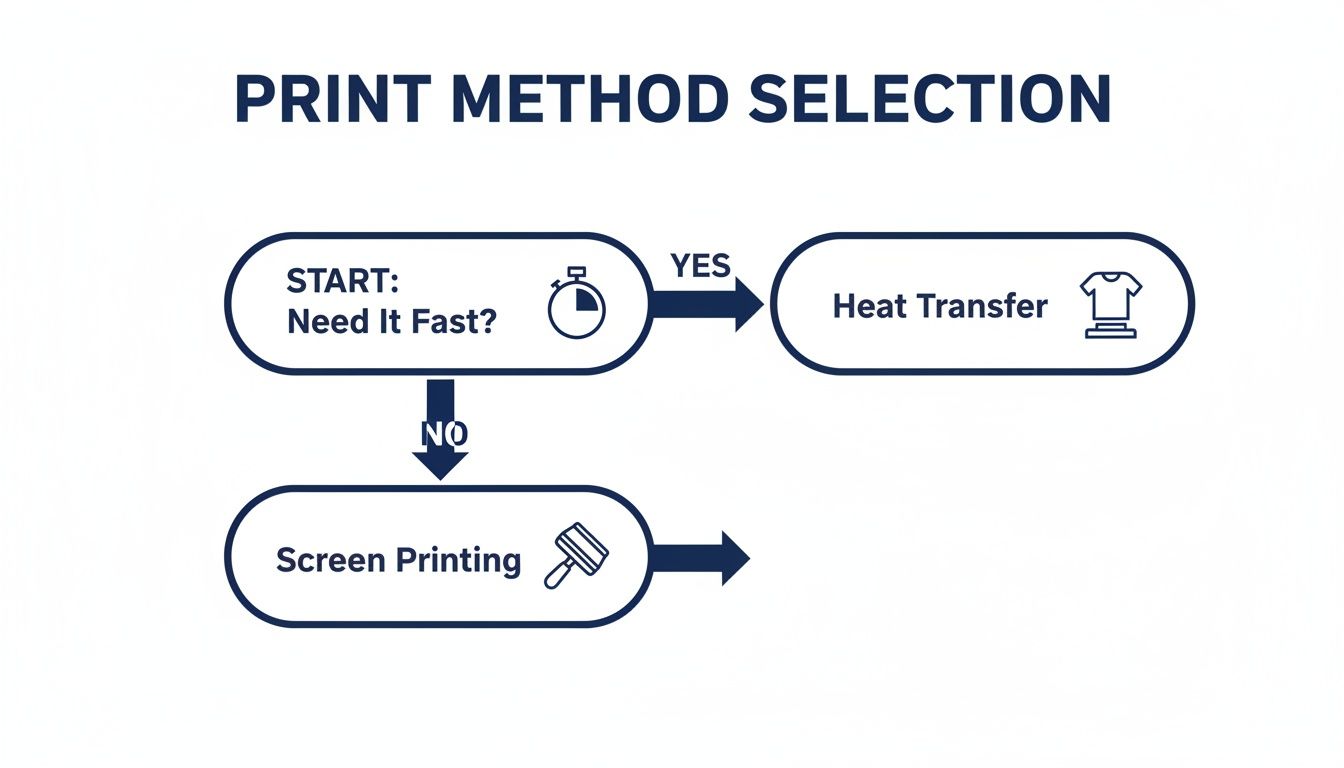

This simple flowchart helps visualize that first critical decision, especially when time is tight.

As you can see, if speed is the name of the game for a small or detailed job, heat transfers give you a direct path to a finished product, letting you skip screen printing's entire setup process.

The DTF Transfer Sweet Spot

Modern DTF transfers have carved out a seriously powerful niche, acting as a flexible hybrid for growing brands. They bring the full-color detail of digital printing but with a durability that gives screen printing a run for its money. This makes them ideal for small-to-medium batches where both quality and flexibility are non-negotiable.

For a growing brand that needs to run 50 shirts of five different multi-color designs, DTF is a total game-changer. The ability to group all those different designs onto a single sheet makes the whole process incredibly cost-effective. You can learn more about how to set this up in our guide to creating your own custom heat transfer designs.

Guidance for Growing Brands: Start with DTF transfers. They give you flexibility and incredible quality right out of the gate. Once a specific design becomes a bestseller and you need to print it in huge quantities (200+), that's the time to look into screen printing for that one design to maximize your margins.

Making a Cost-Effective Decision

The explosion in personalization is what’s fueling the heat transfer market. Valued at USD 3.2 billion in 2025, the market is projected to hit an incredible USD 8.9 billion by 2035, growing at a blistering 10.8% CAGR. That growth is all about the demand for quick-turn, small-batch orders with vivid, tough graphics.

This is exactly where our Auto-build gang sheet builder gives you a critical advantage. It lets you pack multiple designs onto one sheet, which slashes your cost per print. This makes DTF not just a smart choice for quality and flexibility, but an essential economic tool for scaling your business without the massive overhead of screen printing.

Got Questions? We've Got Answers.

Even after laying it all out, you probably still have a few questions rolling around. Let's tackle the most common ones head-on to help you lock in your decision.

Is Heat Transfer Cheaper Than Screen Printing?

For smaller jobs, heat transfer is almost always the cheaper route. Screen printing has a pretty involved setup process—a separate screen has to be burned for every single color in your design. Those setup costs add up fast, making it a tough sell for small batches or one-off prints.

On the other hand, modern heat transfer methods like DTF have next to no setup costs tied to how complex your design is. This makes them perfect for any order size, but especially for those smaller runs. Once you get into big bulk orders, though—think 100+ pieces—screen printing starts to make more financial sense. The setup cost gets spread so thin across all the items that the price per shirt drops way down.

Which Lasts Longer: Screen Print or Heat Transfer?

For years, screen printing has worn the crown for durability. The ink literally becomes one with the fabric fibers, creating a print that can easily outlive the garment itself without cracking or fading. It's the old-school, time-tested method known for just being tough.

But here's the thing: modern DTF (Direct to Film) transfers have pretty much closed that gap. High-quality DTF prints are built for the long haul, engineered for flexibility and often tested to handle 100+ wash cycles without breaking a sweat. While those old, papery heat transfers would crack and peel if you looked at them wrong, today’s professional DTF transfers bring a level of durability that absolutely rivals screen printing.

The Modern Verdict: When done right, both methods deliver fantastic durability. Screen printing is naturally rugged, while high-quality DTF offers a tough, flexible finish that holds up to serious wear and tear. Longevity is no longer the deciding factor it once was; now, it's more about the other needs of your project.

What Does the Final Print Feel Like?

The feel of the print—what we call the "hand"—is a huge point of difference and often a dealbreaker for people.

- Screen Printing: The ink soaks into the fabric, giving you a soft, breathable finish. You can usually feel it, but it moves right along with the garment, so the material keeps its natural feel.

- Heat Transfer: This method lays the design on top of the fabric. Forget those thick, plasticky transfers from the past, though. Modern DTF transfers are incredibly thin, soft, and flexible. It’s a smooth, light feel, but it's definitely a distinct layer on the shirt.

Can I Print on Dark-Colored Fabrics?

Yep, both methods are great on dark garments, they just get there in different ways. Screen printing is fantastic at laying down bright, opaque colors on dark fabrics because you're applying a thick layer of ink. To make colors really pop, printers will often put down a white underbase layer first.

DTF transfers also kill it on dark fabrics. The process automatically includes a white ink layer printed behind the colors, which acts as a built-in underbase. This ensures your design is just as vibrant on a black t-shirt as it is on a white one, with no extra setup or steps needed.

What’s the Best Method for Full-Color Photos?

For photorealistic images, complex color gradients, and designs with a million different shades, heat transfer is the undisputed winner. Digital methods like DTF can reproduce any image with flawless accuracy and detail, just like printing a photo from your camera.

Screen printing, on the other hand, really struggles with photos. It requires a complicated technique called four-color process or simulated process, which uses tiny dots of cyan, magenta, yellow, and black ink to fake a full-color image. It can be done, but it's usually less precise and way more expensive than a simple digital transfer.

How Can I Make Small Batches More Cost-Effective?

This is the million-dollar question for small businesses and growing brands. The single best way to slash costs on varied, small-batch orders is to use gang sheets with your DTF transfers. A gang sheet lets you cram multiple different designs onto one big transfer sheet.

Instead of paying for each design individually, you just pay for the total sheet. This is exactly where a tool like our Auto-build gang sheet builder becomes a game-changer. It automatically and efficiently packs your designs onto the sheet, using every last square inch to drive your cost per print way down. It's how you make small, diverse runs incredibly profitable.

Ready to create vibrant, durable, full-color designs with unmatched ease and affordability? The Lion DTF Transfers Auto-build gang sheet builder makes it simple to optimize your costs and bring any project to life. Build your custom gang sheet today!