When you’re weighing heat transfer vs. screen print, it really boils down to one thing: screen printing is built for cranking out huge orders of simple designs, while heat transfers are the go-to for detailed, full-color graphics on small-to-medium batches. The right choice hinges on whether you need bulk efficiency or on-demand flexibility.

Choosing Your Ideal Printing Method

Picking the right decoration method is one of the most important decisions you'll make when launching a clothing brand or printing custom gear. It directly impacts your costs, what you can design, and how fast you can produce. For decades, screen printing was the undisputed champ for large orders. It's durable and cheap after you get past the high initial setup costs. But it has always struggled with small runs and complex, multi-color designs, since every single color needs its own screen and a separate setup fee.

This old-school model put up a huge wall for small businesses, e-commerce stores, and brands that needed to offer a variety of designs without tying up cash in a mountain of inventory. But today, the game has totally changed. The rise of advanced heat transfer methods, especially Direct-to-Film (DTF), has pretty much closed the quality gap while offering flexibility that was once unthinkable. DTF transfers deliver the same vibrant colors and durability you’d expect from screen printing, but without any of the painful setup.

Understanding the Modern Printing Landscape

There's no single "best" method—it's all about what your specific project needs. Nailing down the fundamental differences is the first step toward making a smart, profitable choice. Key factors like your order size, how complex the design is, and how quickly you need it will point you in the right direction.

For example, if you need 500 shirts with a simple two-color logo, screen printing is a no-brainer. But if you're running an online store with 20 different t-shirt designs that you print as they sell, DTF transfers are far more practical and cost-effective. Modern tools are designed to make this easier than ever. For instance, our Auto-build gang sheet builder simplifies the process, making it easy and cost-effective to combine multiple designs.

The real win for small and medium-sized businesses is the power to produce top-quality, multi-color designs in any quantity—without the financial gamble of screen printing. This is where DTF really shines.

To make this even simpler for businesses, our Auto-build gang sheet builder is an incredibly cost-effective tool. It lets you pack multiple different designs onto a single transfer sheet, which dramatically cuts down your cost per print. This makes it possible to test out new products, handle small custom orders, and stay profitable without being stuck in the old ways of printing. This guide will give you a clear framework to help you pick the perfect technique for your goals.

| Feature | Heat Transfer (DTF) | Screen Printing |

|---|---|---|

| Best For | Small to medium batches, complex designs | Large volume orders, simple graphics |

| Setup Cost | None; print-on-demand model | High; requires a separate screen per color |

| Color Complexity | Unlimited colors and gradients | Limited colors; costly for complex art |

| Turnaround Time | Fast; ideal for quick projects | Slower due to intensive setup process |

Understanding the Core Printing Processes

To really get a handle on the heat transfer vs. screen print debate, you have to understand how each one actually gets a design onto a shirt. They're two completely different worlds. One is a classic, hands-on craft, while the other is driven by modern digital tech.

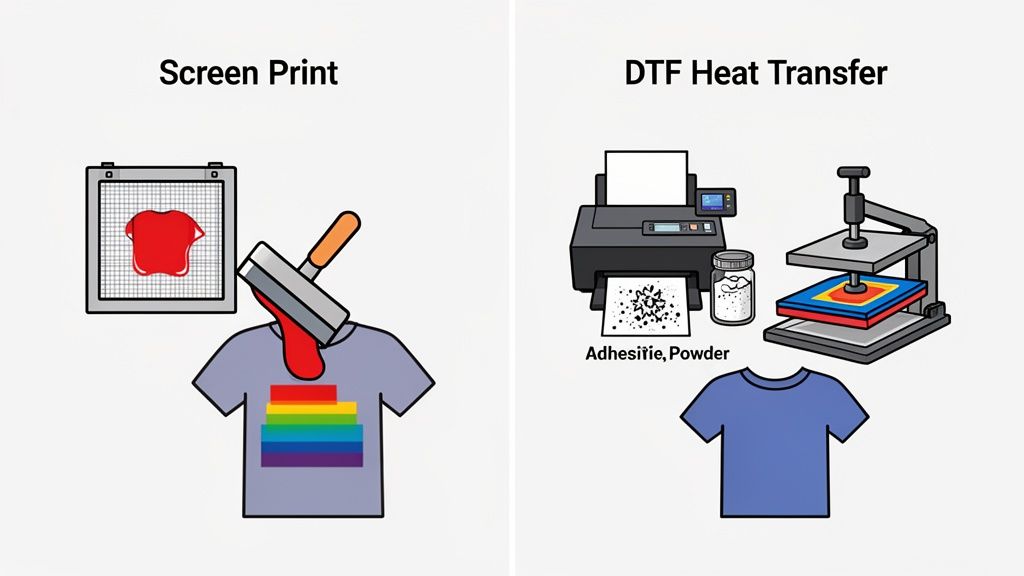

At its heart, screen printing is basically a highly refined stenciling technique. It’s an art form that’s been perfected over decades, making it the undisputed king for large-volume apparel runs. The whole process is methodical and requires a good bit of prep work before any ink hits the fabric.

The Mechanics of Screen Printing

The screen printing workflow is what dictates its costs and capabilities. The big thing to remember is that it requires a separate screen—a unique stencil—for every single color in your design.

- Screen Creation: It starts by coating a fine mesh screen with a light-sensitive emulsion. Your design is printed onto a clear film, laid on the screen, and blasted with powerful light.

- Stencil Formation: The light hardens the emulsion everywhere except where your design is. Those unexposed parts wash away, leaving a perfect stencil for one color layer.

- Ink Application: The screen is placed over the shirt, and a thick, vibrant ink is pulled across it with a squeegee, pushing ink through the stencil. For a multi-color job, you repeat this with a new screen for each color.

- Curing: Finally, the shirt goes through a huge conveyor dryer to cure the ink, making sure it permanently bonds with the fabric.

This layer-by-layer method is why screen printing is fantastic for bold, durable graphics with just a handful of colors. But all that setup makes it a poor choice for small orders or designs with photorealistic detail.

The Modern Heat Transfer Process: DTF

On the flip side, modern heat transfers like Direct-to-Film (DTF) work on a totally different principle. DTF completely skips the messy screen-making process, using digital printers to create a transfer that’s ready to press in minutes, handling unlimited colors and tiny details effortlessly.

Here’s the DTF process in a nutshell:

- Digital Printing: Your full-color design is printed directly onto a special translucent film using water-based inks.

- Adhesive Application: The printed film then gets a dusting of powdered thermoplastic adhesive, which cleverly sticks only to the wet ink.

- Curing the Transfer: The film is heated just enough to melt the adhesive powder into a smooth layer on the back of the print.

- Heat Application: The finished transfer is laid on the garment and pressed with a heat press, which permanently bonds the design to the fabric.

The real magic of DTF is its ability to produce vibrant, photorealistic, full-color designs in one shot, with no color separation or screen setup. This makes it a game-changer for complex art, small batches, and on-demand printing.

This tech has made professional-quality custom apparel accessible to everyone. Here at Lion DTF, we simplify this workflow even further. You just upload your designs, and we handle all the printing and curing. If you want to go deeper, check out our guide on what DTF printing is and how the technology works.

For a great real-world example of how different printing methods are used, take a look at the various methods for name printing on football shirts, where the flexibility of DTF really shines. And to get the most bang for your buck, our Auto-build gang sheet builder offers an easy-to-use and cost-effective way to cram multiple designs onto a single sheet, making even one-off prints incredibly affordable.

A Detailed Cost Breakdown for Different Order Sizes

When you're trying to choose between heat transfer and screen printing, your budget and order size are almost always the deciding factors. The way each method is priced is fundamentally different, and getting a handle on that is key to making a smart, profitable choice for your business.

Let's break down how the costs really stack up for small and large orders.

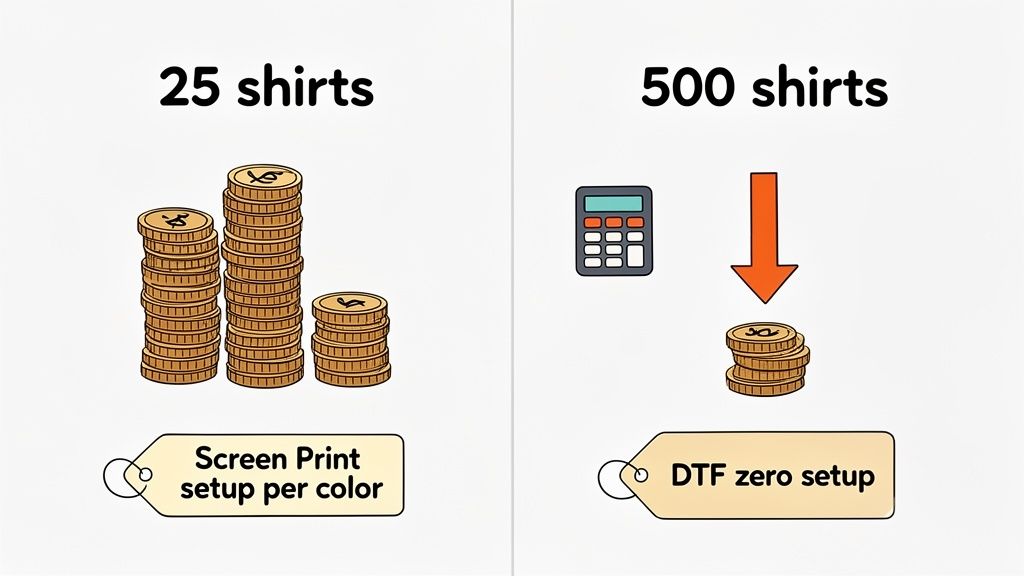

The Screen Printing Cost Structure

Screen printing is built on a classic economy of scale. The process involves a ton of upfront work, and every single color in your design needs its own separate screen. Those setup fees, which often run anywhere from $20 to $50 per screen, can add up fast and make small orders feel way too expensive.

For example, a simple four-color design could easily hit you with $100 or more in setup costs before the first shirt even gets printed. This initial investment is exactly why screen printers have to enforce minimum order quantities—they need a big enough run to absorb those fixed costs and actually make a profit.

But once those screens are made, the cost-per-shirt drops like a rock. Printing more units becomes incredibly fast and efficient, making screen printing the undisputed champ for big-volume runs where that initial setup cost is spread thin across hundreds or thousands of items.

The DTF Heat Transfer Advantage for Small Orders

Direct-to-Film (DTF) heat transfers completely flip that model on its head. Because it’s a digital process, there are zero setup costs. You can print a single, full-color design for the exact same per-unit price as you would for 50. There are no screens to burn and no color layers to separate.

This is a complete game-changer for small businesses, startups, and e-commerce brands that need to stay nimble. It opens the door for:

- One-off samples to test out new product ideas without any risk.

- Small batch orders for special events, local teams, or limited-edition drops.

- True on-demand printing, which means you can kill the need for expensive, risky inventory.

The financial flexibility of DTF lets you be far more agile and responsive to what your customers actually want. You don’t have to guess which designs will be a hit and sink a bunch of money upfront; you just print what you need, right when you need it.

Maximizing Cost-Effectiveness with Gang Sheets

To make DTF even more affordable, you can use a gang sheet—a large transfer film where you can place multiple different designs. This is where a tool like our Auto-build gang sheet builder becomes absolutely essential for your business. Its ease of use makes filling a single sheet with various logos, tags, and graphics incredibly simple, driving the cost-per-image down to just cents.

This strategy is incredibly powerful for squeezing every bit of profit out of an order. To see exactly how it works, check out our guide on creating and using DTF gang sheets.

With DTF transfers, there’s no financial penalty for design complexity or small quantities. You get the freedom to offer a wide variety of full-color products without the steep initial investment that traditional screen printing demands.

This difference is clearly reflected in market trends. While screen printing still holds a major market share for bulk production, the heat transfer market is growing much faster, fueled by its flexibility and low entry costs, which perfectly suit modern e-commerce needs.

To give you a tangible sense of the financial tipping point, here’s a practical comparison.

Cost and Time Comparison Screen Print vs DTF Heat Transfer

This table breaks down the typical costs and time investments for a small (25 shirts, 4 colors) and large (500 shirts, 4 colors) order using both methods.

| Metric | Screen Printing (25 Shirts) | DTF Transfer (25 Shirts) | Screen Printing (500 Shirts) | DTF Transfer (500 Shirts) |

|---|---|---|---|---|

| Setup Fee | ~$120.00 (4 screens @ $30/ea) | $0.00 | ~$120.00 | $0.00 |

| Cost Per Print | ~$5.00 | ~$3.50 | ~$1.50 | ~$3.50 |

| Total Cost | ~$245.00 | ~$87.50 | ~$870.00 | ~$1,750.00 |

| Time to Print | 2-4 hours (includes setup) | ~30 minutes (press time) | 5-7 hours (includes setup) | 5-6 hours (press time) |

As the numbers show, DTF is the clear financial winner for small orders. For a 25-shirt run, it's significantly cheaper and faster. But once you scale up to a 500-shirt order, screen printing’s lower per-unit cost takes over, making it the more economical choice. This shows you exactly where that financial tipping point lies.

Comparing Design Quality, Durability, and Feel

Beyond the nuts and bolts of cost and production, what really counts is the final product. How a design looks, feels on the shirt, and holds up over time are what keep customers coming back. When you put heat transfers and screen printing side-by-side, the differences in quality, durability, and feel become clear—and they all come down to how the graphic gets onto the fabric.

Color Vibrancy and Detail Accuracy

Screen printing has always been the king of bold, punchy colors. Because the ink is pushed right into the fabric, you get a rich, opaque finish that really pops, especially on darker garments. But that strength in color saturation is also its biggest weakness when it comes to detail.

The process just can't handle photorealistic images, smooth gradients, or super fine lines well. Every color needs its own screen, so complex designs with lots of tones become either ridiculously expensive or just technically impossible to get right.

This is where modern heat transfers—especially DTF—completely change the game. DTF is a digital process, printing your design in full resolution and capturing every single tiny detail and color gradient perfectly. It can lay down millions of colors in one pass to create prints that are stunningly sharp and vibrant.

Wash Durability and Longevity

For a long time, durability was screen printing’s claim to fame. Traditional plastisol inks create a serious bond with fabric fibers and are known to take dozens of washes before they even think about cracking or fading. For stuff that gets a lot of wear, like work uniforms or band merch, that longevity is a huge deal.

But heat transfer technology has caught up in a big way. High-quality DTF transfers, like ours at Lion DTF, are built for the long haul. We've put our transfers through the wringer, testing them to withstand 100+ wash cycles without any cracking, peeling, or fading. That’s longevity that goes toe-to-toe with, and often beats, traditional screen printing.

This kind of performance means those intricate, full-color designs you create stay crisp and vibrant for the entire life of the garment. You’re giving your customers a premium, long-lasting product that combines digital precision with screen print-level durability.

The Feel of the Print

The "hand" of a print—how it actually feels on the fabric—is a critical part of quality that often gets overlooked. It impacts everything from comfort to the perceived value of the shirt.

Screen printing, particularly with thick layers of plastisol ink, can feel a bit raised and heavy. While some people like that classic, thick texture, a design with a lot of colors can feel like a plastic shield on your chest—stiff and not very breathable.

DTF transfers deliver a totally different experience. The print is lightweight, flexible, and soft to the touch. Because the design is applied as a single, thin layer, it moves right along with the fabric, giving you amazing comfort without sacrificing color or durability.

This soft-hand feel is a massive advantage, especially for fashion apparel or anything where comfort is key. For a deeper dive, check out our article on exactly how a DTF transfer should feel on a finished shirt.

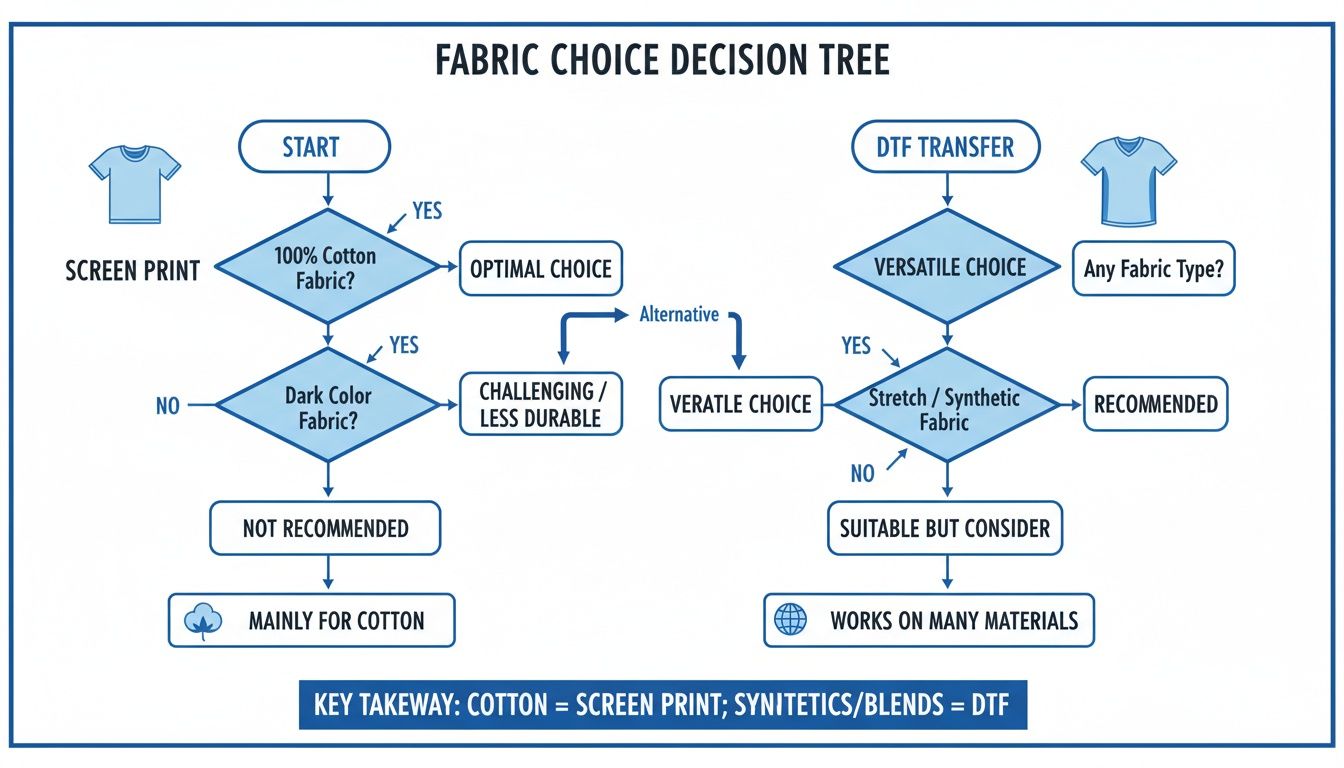

Fabric Compatibility: Where Can You Print?

The material you're printing on is a huge deal. A design that looks amazing on a cotton t-shirt can completely fall apart on a polyester jersey if you use the wrong method. This is a make-or-break factor in the heat transfer vs. screen print debate, because fabric compatibility directly impacts the quality of your final product.

Screen printing really made its name on natural fibers. It works beautifully on 100% cotton and most cotton/poly blends, where the ink can sink in and bond with the fabric. That makes it a solid, reliable choice for standard tees, hoodies, and tote bags.

But that's also where its flexibility starts to run out. Try to screen print on heat-sensitive synthetics like polyester or nylon, and you'll need special, pricey inks and additives to stop dye migration—that frustrating issue where the fabric's color bleeds into your print. It just adds a layer of complexity and cost that narrows its use.

The All-Surface Advantage of DTF Transfers

This is where DTF heat transfers really pull ahead. Because of how they're applied, they stick flawlessly to a massive range of materials without needing special inks or complicated tweaks. For any brand looking to expand its product line, this adaptability is a game-changer.

Lion DTF transfers are built for this kind of versatility. They work perfectly on:

- Cotton and Cotton Blends: The go-to for apparel, giving you a soft feel and a vibrant finish.

- Polyester and Performance Wear: Perfect for athletic jerseys and moisture-wicking gear where screen printing often struggles.

- Nylon and Tri-Blends: Great for jackets, bags, and trendy blended fabrics.

- Denim and Canvas: Lets you create durable, high-impact designs on tougher materials.

- Leather and Wood: Opens the door to unique accessories and promo items you couldn't print on before.

Being able to print on this many surfaces means you can grow your product line without having to buy different equipment or stock a dozen types of ink for every new material you want to try.

Real-World Scenarios, New Opportunities

Let's say you get an order to outfit a local sports team. Their jerseys are 100% polyester, their warm-up hoodies are a cotton/poly blend, and their duffel bags are made from tough nylon. With screen printing, this job would be a logistical nightmare, demanding different inks and curing methods for each item.

With DTF, the process is exactly the same for all three. You can put the jersey numbers, team logos, and player names all on a single sheet with our Auto-build gang sheet builder, making the whole thing incredibly easy to use and cost-effective. You just press the same transfer onto each different fabric and get consistent, professional results every time.

DTF’s ability to work across so many fabric types with one simple process removes the barriers that hold you back. It lets you say "yes" to more jobs, from custom denim jackets to branded leather patches, all with the same solution.

This kind of flexibility gives you a serious competitive edge. You're not stuck just printing t-shirts anymore. You can decorate tricky items like hats, backpacks, and even shoes, tapping into entirely new markets. This unmatched versatility is what makes DTF the clear choice for modern apparel decorators who need to adapt and offer a wide range of custom products.

Making the Right Choice for Your Project

Figuring out whether to go with heat transfers or screen printing doesn't have to be complicated. It really just comes down to asking a few key questions about your specific project. Once you know what to look for, you'll be able to spot the most practical and profitable method every single time.

This simple framework will steer you in the right direction, making sure you nail the choice for your apparel goals.

A Practical Decision-Making Framework

Here are the four questions you need to ask to get it right.

1. How Many Items Are You Printing?

This is almost always the first and most important factor. If you’ve got a big order—think 50 or more identical pieces—screen printing’s economy of scale kicks in, making it the cheaper option. But for small batches, one-off custom jobs, or any print-on-demand needs, DTF heat transfers win hands-down because there are zero setup fees.

2. How Complex Is Your Design?

Take a hard look at the artwork. Is it a simple logo with just one or two solid colors? Screen printing is a great, classic choice for that. But if you're dealing with photorealistic images, super fine details, or designs loaded with colors and gradients, DTF is in another league. It nails complex graphics with perfect accuracy in a single, simple pass.

3. What Fabric Are You Using?

The material you're printing on is a huge deal. Screen printing is king on cotton, but it gets tricky and requires special (and often expensive) inks for synthetics like polyester. On the other hand, DTF transfers are incredibly versatile. They stick flawlessly to cotton, polyester, nylon, and all sorts of blends without you having to change a thing about your process.

This visual shows you just how much of an advantage DTF has when you're working with different fabrics.

As you can see, screen printing is solid for cotton, but DTF gives you the freedom to print on pretty much anything you can fit in a heat press.

4. What Is Your Deadline?

Let’s be real: time is money. The setup for screen printing is a process, and that makes it slower for rush jobs. DTF transfers offer a much, much faster turnaround. If you have a tight deadline, DTF is the way to go. You can get your transfers, press them, and have orders out the door in a fraction of the time.

For any modern apparel business that needs speed, vibrant colors, and the ability to print on anything, DTF heat transfers are consistently the smarter solution. They get rid of the old-school printing headaches, letting you meet all kinds of customer demands without breaking a sweat.

Our Auto-build gang sheet builder makes this even easier. Its user-friendly interface helps you quickly and cost-effectively produce a bunch of different designs for various fabrics, all at once. It’s the perfect tool for any shop that needs to stay flexible and fulfill orders fast.

Frequently Asked Questions

When you're weighing heat transfer vs. screen printing, a few questions always seem to pop up. Getting straight answers is key to moving forward with confidence and picking the right method for your goals.

Which Method Is More Profitable for a Small Business?

For most small businesses and startups just getting their footing, DTF heat transfers are the clear winner on profitability. The biggest reason? The barrier to entry is incredibly low, and you don't have to worry about the minimum order requirements that make screen printing so expensive upfront.

With DTF, you can print a single, full-color shirt just as easily as you can a complex batch of different designs—all without a financial penalty. This flexibility lets you run a print-on-demand model, which keeps inventory risk at zero and helps you make money on every single sale, no matter how small.

For a small shop, profitability isn't just about the per-unit cost on a massive order. It's about being able to sell a wide variety of designs in small batches without tying up cash in stock that might not sell. DTF was practically built for this.

To squeeze even more profit out of your runs, our Auto-build gang sheet builder is a game-changer. It’s easy to use and lets you pack multiple designs onto a single sheet, which drops your per-image cost way down and makes even one-off prints incredibly affordable and cost-effective.

Is a Professional Heat Press Necessary for DTF Transfers?

Yes, a professional heat press is absolutely essential. If you want quality, durable results with DTF transfers, there's no way around it. It's tempting to think a home iron can do the job, but it simply can't provide the consistent temperature and even pressure required for the adhesive to properly bond with the fabric.

Trying to use an iron is a recipe for disaster. You'll almost certainly end up with prints that peel, crack, and look terrible after the first wash. A decent heat press is a critical investment for any serious apparel business, as it’s the only way to get the durable, professional finish your customers expect.

Is Screen Printing More Eco-Friendly Than Heat Transfer?

Generally speaking, modern heat transfer methods like DTF are actually more environmentally friendly than traditional screen printing. The screen printing process is a huge water consumer and often relies on harsh chemical solvents for cleaning and reclaiming screens between jobs.

DTF, on the other hand, is a digital process that's almost completely waterless. It also produces very little waste because you're only printing exactly what you need. Plus, many high-quality DTF inks are water-based and Oeko-Tex certified, making them a much more sustainable choice for brands focused on minimizing their environmental footprint.

Ready to create stunning, durable custom apparel with unmatched flexibility? At Lion DTF Transfers, we make it simple to get professional-quality prints for any project, big or small. Explore our premium DTF transfers and start building your order today!