Step into the world of custom apparel, where a plain t-shirt becomes a canvas for your brand, your art, or your message. This guide is here to cut through the noise and show you the ropes of t-shirt printing, helping you pick the perfect method whether you're launching a clothing line, outfitting your team, or just making a single, killer shirt.

Navigating the World of Custom Apparel

The custom t-shirt game is way more than a small niche—it's a creative engine for businesses, artists, and anyone with an idea. From merch tables to corporate events, the power to put a design on fabric is a cornerstone of personal and commercial expression. It's no surprise that this demand has fueled some serious innovation in printing tech.

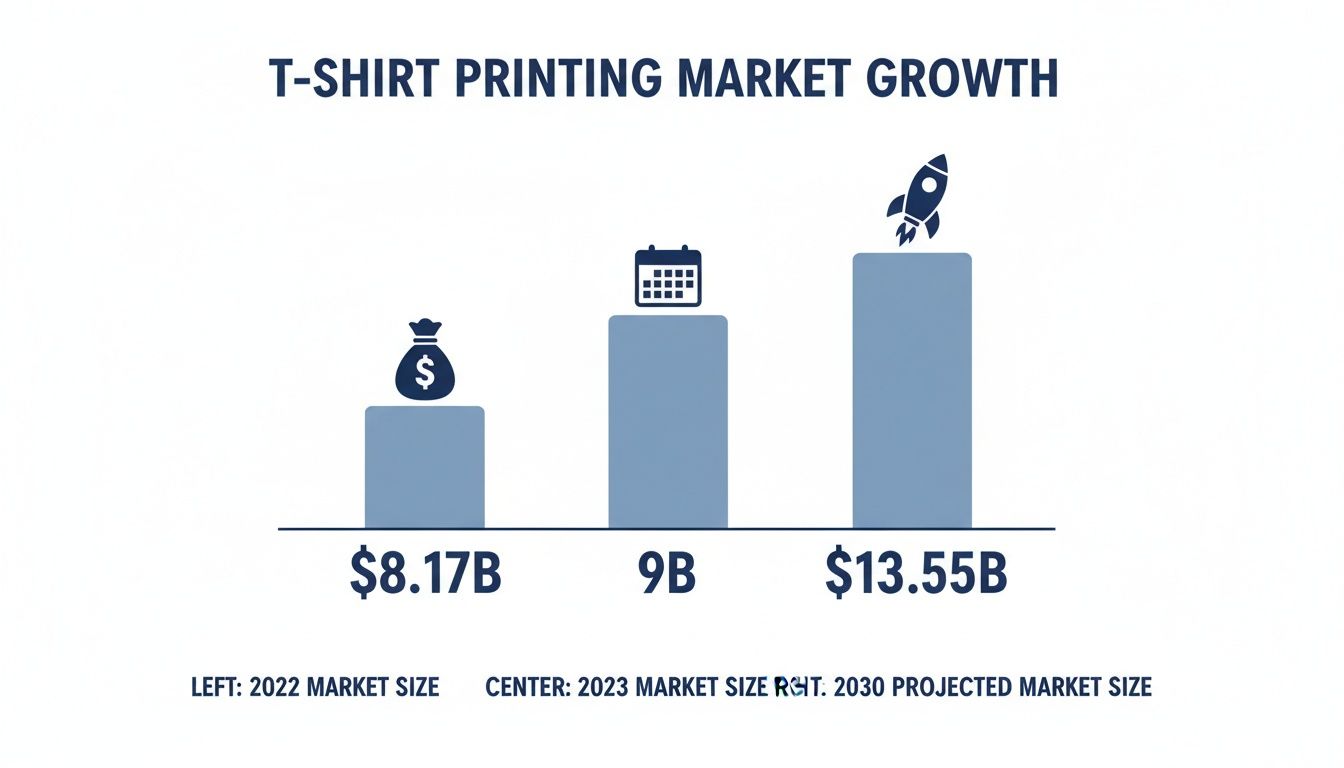

And the numbers don't lie. The global market for custom t-shirt printing was recently pegged at $8.17 billion, with projections hitting $13.55 billion by 2029. This boom is all about the move toward digital, on-demand services that put professional-quality printing in everyone's hands. You can get the full scoop on the t-shirt printing industry's growth from GlobeNewswire.

Understanding Your Printing Options

Choosing the right t-shirt printing method is the single most important decision you'll make. It directly impacts how your final product looks, feels, holds up in the wash, and what it costs you to produce. Each technique has its own strengths, making one a better fit for certain jobs over others.

At its core, t-shirt printing is about matching the right technology to your vision. The perfect method for a 500-shirt corporate order is rarely the best choice for a small, multi-color Etsy design.

To make a smart call, you need to know the main players. This guide will break down the four most important methods in the industry today:

- Direct-to-Film (DTF): The versatile workhorse. Designs are printed on a special film, then heat-pressed onto the shirt. It’s known for brilliant colors that pop on any fabric, from cotton to polyester.

- Direct-to-Garment (DTG): Think of it like a high-end inkjet printer for clothes. It applies ink right onto the fabric, which is fantastic for super-detailed, full-color photos on cotton shirts.

- Screen Printing: The classic, time-tested technique. It uses stencils (screens) to push ink onto a shirt one color at a time. It’s incredibly cost-effective for large runs of simpler designs.

- Heat Transfer Vinyl (HTV): Perfect for bold, simple graphics. Designs are cut from sheets of colored vinyl and then heat-pressed onto the garment. This is the go-to for names and numbers on jerseys.

We’ll get into the nitty-gritty of how these methods stack up. Plus, we'll show you how tools like our Auto-build gang sheet builder make modern methods like DTF unbelievably easy and cost-effective, helping you turn your ideas into pro-quality apparel.

Comparing The Top T-Shirt Printing Methods

Picking the right t-shirt printing method feels a lot like choosing a tool for a job—you wouldn't use a sledgehammer to hang a picture frame, right? Each technology has its own sweet spot, making it perfect for some projects and a total headache for others. The choice you make directly impacts your cost, quality, and how fast you can get things done.

To make sense of it all, let's break down the four heavy hitters in the industry: Direct-to-Film (DTF), Direct-to-Garment (DTG), Screen Printing, and Heat Transfer Vinyl (HTV). Getting a handle on how they stack up against each other is the key to creating pro-level apparel that actually matches your vision and budget. And with the market for custom tees booming, there's never been a better time to get it right.

In fact, the custom t-shirt market is on a serious growth spurt, climbing from $8.17 billion in 2022 to a projected $13.55 billion by 2030.

That steady climb just goes to show how much demand there is for custom gear. Choosing the smartest printing tech for your needs is how you grab a piece of that pie.

Direct-to-Film (DTF): The Versatile Powerhouse

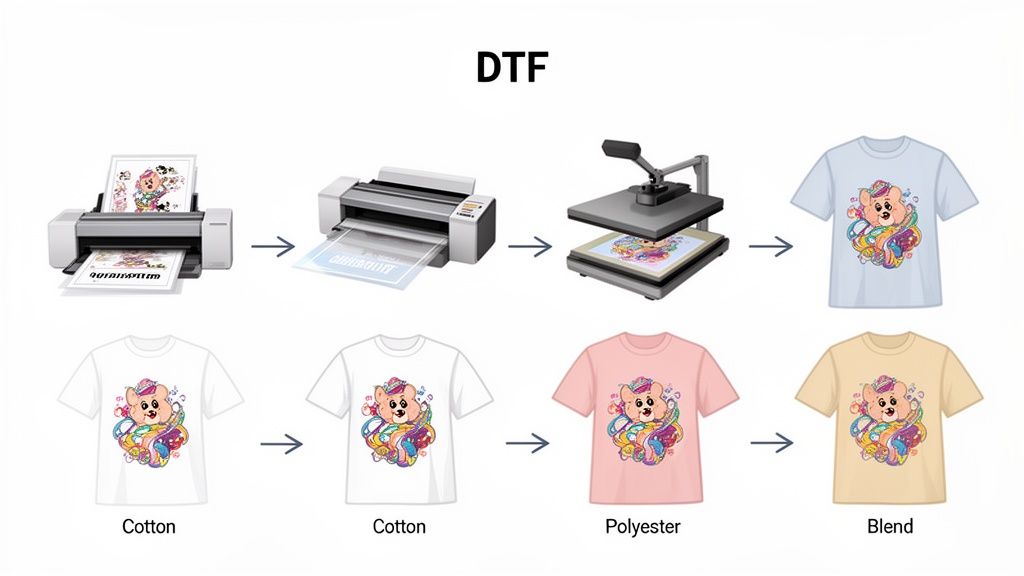

DTF printing is a clever hybrid that borrows the best features from other methods. First, your design is printed onto a special film. Then, it's simply heat-pressed onto the garment. This two-step process is what makes it so incredibly versatile.

The biggest win for DTF is its fabric freedom. It works beautifully on cotton, polyester, nylon, fleece, and just about any blend you can throw at it—light or dark—all without needing messy pre-treatments. This makes it a fantastic all-around solution for anyone printing on a wide range of products.

DTF prints are also known for their ridiculously vibrant colors, crisp details, and amazing durability. A quality transfer can easily handle dozens of washes without cracking or fading, all while keeping a soft, flexible feel that moves right along with the fabric.

Direct-to-Garment (DTG): The Digital Artist

Think of DTG printing like your desktop inkjet printer, but built for clothes. A specialized print head sprays water-based inks directly onto the fabric, allowing them to soak right into the fibers. This is the go-to method for creating photorealistic images with millions of colors and super-fine details.

But DTG definitely has its limits. It performs best on 100% cotton or high-cotton blends because natural fibers do the best job of absorbing the ink. If you're printing on dark shirts, you'll need a white underbase, which can change the feel of the fabric a bit. For a deeper dive, our guide comparing DTF vs DTG printing breaks it all down.

DTG is the master of one-off, highly detailed prints on cotton. It excels at capturing the nuance of a photograph or a complex illustration, but its fabric limitations and slower per-item print time make it less suitable for large, varied orders.

Screen Printing: The Bulk King

Screen printing is the OG champion of the t-shirt world and still reigns supreme as the most cost-effective method for massive orders. The process involves creating a stencil (or "screen") for each color in your design. Ink is then pushed through that screen onto the shirt, one color at a time.

Because of all the setup involved, screen printing just isn't practical for small runs or designs with a ton of colors. But once those screens are ready? You can crank out hundreds or even thousands of shirts quickly and for cheap. The ink sits on top of the fabric, creating a thick, tough, and incredibly vibrant print.

This makes it the number one choice for:

- Event Merchandise: Uniform shirts for a festival or marathon.

- Corporate Branding: Large orders of company shirts with a simple logo.

- Band Merch: High-volume prints with just one or two colors.

Heat Transfer Vinyl (HTV): The Personalization Pro

Heat Transfer Vinyl, or HTV, is all about cutting designs from a sheet of colored vinyl and then using a heat press to apply them to a shirt. It’s the perfect method for simple, bold graphics like names, numbers on a jersey, or single-color logos.

HTV gives you a clean, crisp finish and comes in a huge range of styles, including glitter, metallic, and even fuzzy flocked textures. While it's not the right tool for complex, multi-color images, it’s a fantastic choice for personalization and small-batch orders that need bold, durable graphics without a complicated setup.

T-Shirt Printing Method Comparison

Seeing it all side-by-side can really help clear things up. This table breaks down how each method stacks up across the factors that matter most when you're making a decision.

| Method | Best For | Feel on Fabric | Durability | Color Vibrancy | Cost (Low Volume) | Cost (High Volume) |

|---|---|---|---|---|---|---|

| DTF | Full-color on any fabric; versatile | Soft, flexible layer on top | Excellent | Excellent | Moderate | Low |

| DTG | Photos on 100% cotton | Very soft, ink-dyed feel | Good | Very Good | Moderate | High |

| Screen Printing | Simple designs in bulk | Thick, raised layer | Excellent | Excellent | High | Very Low |

| HTV | Names, numbers, simple logos | Varies; can be thick | Very Good | Good | Low | High |

Ultimately, the best t-shirt printing method comes down to your project. What’s your design, what's your fabric, and how many are you making? While DTF offers some serious advantages in flexibility and quality, it's always smart to know your options. For example, some shops might also Explore another popular custom apparel technique, sublimation printing when working with specialty polyester gear. By weighing these factors, you can confidently pick the right tech to bring your creations to life.

Why DTF Is a Game Changer for Custom Apparel

Direct-to-Film printing, or DTF, is completely shaking up the custom apparel world. It’s a refreshingly simple process that sidesteps many of the headaches that come with other printing methods. You just print a design onto a special film, dust it with an adhesive powder, and press it onto your garment with a heat press. That’s it. The result is a professional, vibrant print with surprisingly little effort.

The real magic of DTF is its incredible versatility. Forget being locked into one type of fabric. While DTG struggles with polyester and sublimation demands it, DTF just works. Cotton, poly, fleece, leather, nylon, blends—you name it, you can probably press a DTF transfer onto it. This opens the door to printing the same full-color, killer design on a whole range of products, from cotton tees to poly hoodies, without ever changing your workflow.

Unlocking Unmatched Quality and Durability

Beyond its "print-on-anything" freedom, DTF is getting noticed for the sheer quality of the final product. The prints are bright and crisp, with razor-sharp details that sit right on top of the fabric. It handles fine lines and complex color gradients with an accuracy that can give screen printing a run for its money, but without any of the color count limitations.

Durability is another huge win. These prints have a soft, flexible feel that stretches with the fabric, which means they resist the cracking and peeling that can ruin a good design.

Premium DTF transfers are built to last. We put our transfers through the wringer, testing them to withstand over 100 wash cycles to make sure the design looks just as good months down the road as it did on day one.

This kind of reliability makes DTF a solid choice for anyone who needs a professional finish that holds up, whether you're creating high-end retail merch or durable workwear.

Driving the Growth of Personalized Apparel

The timing for DTF couldn't be better, as it taps directly into the massive demand for personalized gear. Customization is the engine of the modern t shirt printing industry, a market that hit $5.16 billion recently and is on track to nearly double to $9.82 billion by 2030. A huge part of that growth is coming from startups and brands using custom tees as powerful marketing tools.

Digital methods like DTF are at the center of this trend, growing at a massive 12.5% each year. They make small, cost-effective print runs possible, which is perfect for everyone from hobbyists to promotional agencies. This shift means small businesses and solo creators can finally compete on quality without needing a massive budget. As you build your brand, it's key to learn how to promote custom apparel on TikTok and drive sales to reach a wider audience.

Efficiency and Accessibility for Everyone

Maybe the biggest impact DTF has had is making professional-grade t shirt printing accessible to almost anyone. The startup costs and learning curve are way lower than traditional screen printing, leveling the playing field for businesses of all sizes.

This efficiency gets a serious boost from tools designed to cut waste and maximize every dollar you spend. Here’s how you can make your production incredibly streamlined:

- Gang Sheets: Instead of printing designs one by one, you can pack multiple images onto a single large transfer film, called a gang sheet.

- Smart Layouts: By arranging your main graphics, logos, and sleeve prints all on one sheet, you dramatically drop the cost of each individual print.

- Builder Tools: Our Auto-build gang sheet builder makes this ridiculously easy. Just upload your artwork, and the tool helps you arrange everything to use every last square inch of film, ensuring cost effectiveness.

This approach makes DTF not just a high-quality option, but a seriously cost-effective one. It empowers Etsy sellers, local print shops, and growing brands to produce top-tier apparel affordably, turning great ideas into profitable products without the heavy overhead.

How to Maximize Efficiency with DTF Gang Sheets

Once you’ve locked in DTF as the right tool for your t shirt printing projects, the next question is always the same: how do you make it as smart and affordable as possible? The secret to serious cost savings isn’t some complicated industry trick—it’s just about being smart with your space. This is where a gang sheet becomes your most valuable asset.

Think about it like baking cookies. You wouldn't put one cookie on a giant baking sheet and call it a day. You'd fill that sheet up to make the most of your oven space and time. A gang sheet takes that exact same logic and applies it to DTF transfers. It's one large film that holds multiple different designs, all grouped together.

When you print all your designs at once on a single sheet, you stop paying for each individual transfer. Instead, you're just paying for the total area of the film, which can dramatically slash the cost of each image. This simple shift turns t shirt printing from a one-off job into a bulk production process, even when all your designs are completely different.

What Is a Gang Sheet and How Does It Work?

A gang sheet is just a collection of different art files arranged—or "ganged up"—onto a single printable sheet. For creators, this is an absolute game-changer. Let's say you're launching a new clothing drop. You've got a main chest design, a small logo for the sleeve, a custom tag print, and a graphic for a matching hat.

Instead of ordering four separate transfers, you can place all of them onto one sheet. Now, with a single print run, you have all the components you need, ready to be cut apart and pressed.

The real benefit of a gang sheet is maximizing the value of every single square inch of film you buy. The more designs you can fit, the lower your per-print cost drops, making professional-quality printing a reality for any budget. This is made incredibly easy and cost-effective with our Auto-build gang sheet builder.

This efficiency is a lifeline for small businesses. Etsy sellers can combine orders for several different customers onto one sheet. Brands can produce a variety of designs for a photoshoot without being forced to buy a huge inventory of any single one. It’s all about flexibility and cost control.

The Power of Automation in Building Your Sheet

Manually arranging designs can feel like a frustrating game of Tetris. You have to carefully rotate, resize, and nest every image to avoid wasting precious space, a process that often requires design software and a whole lot of patience. This is where automation changes everything.

Our Auto-build gang sheet builder was designed specifically to eliminate that headache. It’s an intuitive tool that does the heavy lifting for you, turning a complex layout task into a simple drag-and-drop process.

Here’s how it improves your t shirt printing workflow:

- Easy Uploads: Just upload all the image files you need for your various projects.

- Automatic Arrangement: The builder intelligently nests your designs, rotating and placing them to get the tightest fit possible for maximum cost effectiveness.

- Instant Optimization: You can watch in real-time as the tool maximizes your sheet space, guaranteeing you get the absolute lowest cost per image.

- Total Control: If you want to tweak things, you still have full control to resize, duplicate, or reposition any design on the sheet.

By using a smart tool like this, you take the guesswork out of the equation and ensure you’re getting the most prints for your money, every single time. For anyone serious about scaling their operation, mastering these tools is non-negotiable. To become an expert, you can dive deeper by reading our complete guide on what are dtf gang sheets. This level of efficiency empowers everyone from hobbyists to large-scale print shops to produce more for less.

Your Step-By-Step Guide to Pressing Perfect Transfers

This is where the magic happens—turning a digital design on a piece of film into a finished, wearable garment. While it might look a little technical, pressing a DTF transfer is a straightforward process that anyone can master with just a little practice. I'll break it down into a few simple, actionable steps to make sure you get pro-level, durable results every single time.

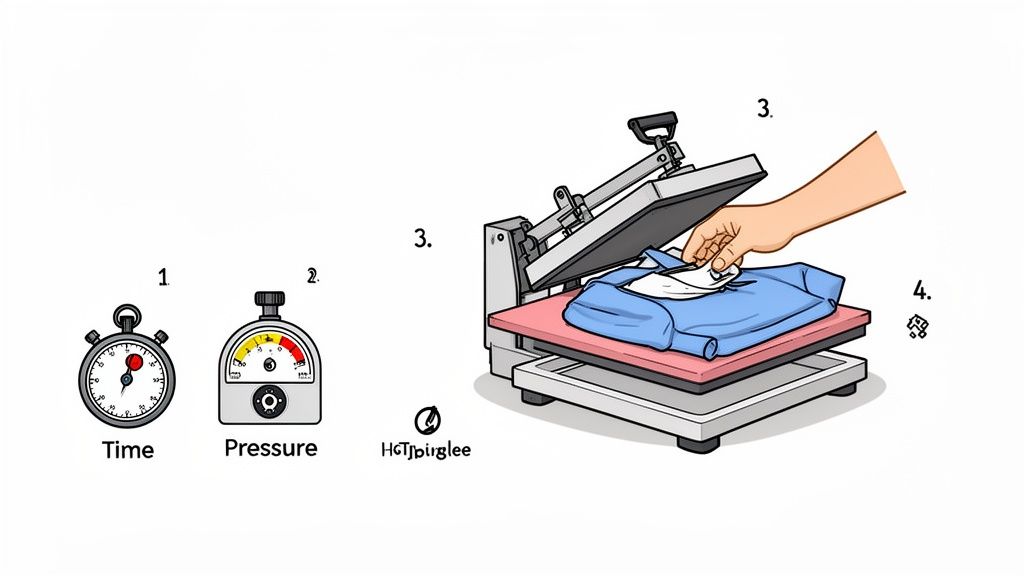

Before you even think about placing your transfer, a little prep work goes a very long way. Start by pre-pressing your garment for about 5-10 seconds. This quick step pulls out any hidden moisture and smooths out wrinkles, giving you a perfectly flat, dry surface for the transfer to stick to. Trust me, a prepped canvas is essential for the best adhesion.

Setting Up for Success

With your shirt ready, it’s time to get the transfer in position. Lay your DTF transfer on the garment with the glossy, printed side facing up. The matte, adhesive side should be touching the fabric.

Take a second to make sure it's perfectly centered and straight. If you're worried about it moving, a little heat-resistant tape can lock the design in place and prevent any shifting when you close the press.

Next up is dialing in your heat press settings, which is arguably the most crucial part of the whole process. For most standard fabrics like cotton and polyester blends, these are your go-to numbers:

- Temperature: 240-280°F

- Time: 10 seconds

- Pressure: Medium to firm

These settings create the perfect environment for the adhesive to melt and bond permanently with the garment’s fibers. We’ve got more specific recommendations in our detailed guide on heat press settings for DTF transfers if you want to get more granular.

The Perfect Press and Peel

Once your settings are locked in, close the heat press and let it do its thing. As soon as that timer beeps, open the press smoothly and get ready for the big reveal. Our transfers are designed for a hot peel, which means you can pull that film right off while the garment is still hot.

To get a flawless peel, just grab a corner of the film and pull it back in one smooth, continuous motion. Try not to yank or stop halfway through, as that can mess with the transfer. A clean peel will leave you with a vibrant, perfectly applied design.

Pro Tip: Want an even softer hand-feel and a little extra durability? Do a quick second press. Cover the design with a Teflon sheet or parchment paper and press again for just 5-7 seconds. This helps meld the ink even deeper into the fabric for a true premium finish.

By following this simple checklist, you take all the guesswork out of the equation and can confidently produce top-quality apparel.

Finding the Right Print Partner For Your Project

Picking the perfect t shirt printing method is only half the job. Finding a reliable partner to actually bring your designs to life? That's just as critical. The final quality of your shirt hinges entirely on your partner’s obsession with precision, speed, and genuine support. When you’re looking around, there are a few things that are absolutely non-negotiable.

A real partner gets that color is everything. They should have a dialed-in color-matching process to make sure the vibrant red or deep navy on your screen is exactly what shows up on the finished shirt. Durability is right up there, too—ask them how they test their stuff. Here at Lion DTF, our transfers are put through the wringer, tested to hold up for over 100 washes. That’s our guarantee that your designs won’t crack, peel, or fade out after a few laundry cycles.

Speed and Support Are What Really Separate the Good from the Great

In a world where everyone wants everything yesterday, turnaround time can make or break a project. You need a partner who moves fast, like our standard 1-2 day turnaround, with options for next-day air or even same-day pickup if you're local. That kind of agility is huge, especially with the demand for on-demand merch growing like crazy.

The custom apparel market is massive—we’re talking $185.2 billion massive—and digital methods like DTF are growing at a blistering 12.5% CAGR. This just proves how essential it is to have a reliable partner who can hit deadlines without cutting corners on quality. You can dive deeper into the global t-shirt market stats over on Impressions Magazine.

A great printing partner doesn’t just print and ship. They’re an extension of your team, giving you the tools and support you need to win. Their success is tied directly to yours.

Top-tier support is more than just answering emails. A true partner offers services that actually make your life easier and your workflow smoother. That could look like:

- Design Help: Offering vectorization services to sharpen up your artwork and get it print-ready.

- Expert Assistance: Providing hands-on help, like our "We Build a Gang Sheet for You" option.

- Real Human Access: Being available by call, text, or chat to sort out issues fast.

- Smart Tools: Building things like our Auto-build gang sheet builder to make ordering simple and more cost-effective.

At the end of the day, you prove consistency and trust through experience. With thousands of 5-star reviews, we stand by our promise to deliver exceptional quality, every single time. It’s that dedication that makes creators and businesses trust us to be the reliable partner behind their brand.

Got Questions About T-Shirt Printing? We’ve Got Answers.

Jumping into the world of custom apparel always brings up a few questions. To make sure you’re moving forward with total confidence, we’ve tackled some of the most common things people ask about t-shirt printing. Let’s clear things up so you can get back to creating.

What Is the Most Durable T Shirt Printing Method?

This is a big one. While old-school screen printing has a solid reputation for being tough, today’s Direct-to-Film (DTF) transfers are engineered to go the distance. In fact, high-quality DTF can easily match—and often beat—other methods, especially when you’re dealing with complex, multi-color designs.

Our premium DTF transfers are built to last, tested to withstand over 100 washes without cracking, peeling, or fading. You get a professional, retail-quality finish that stays vibrant.

Can I Use a Home Iron for DTF Transfers?

We get this question a lot, but the answer is a hard no. For professional results, you absolutely need a proper heat press. A heat press is built to deliver two things a home iron can't: perfectly even heat and consistent, heavy pressure. Both are critical for correctly bonding the transfer’s adhesive into the fabric fibers.

An iron creates hot spots and applies pressure unevenly, which is a recipe for a failed transfer. You’ll end up with peeling edges, a patchy finish, and a print that won't last. It just isn't worth the risk.

How Do I Create a Gang Sheet to Save Money?

Using a gang sheet is, without a doubt, the smartest and most cost-effective way to order multiple DTF transfers. The idea is simple: you arrange several different designs onto one large sheet of film, which dramatically drops your cost per image.

The best way to control your t-shirt printing costs is to maximize every single square inch of your transfer film. A gang sheet makes that happen, whether you're ordering a few designs or a few hundred.

Our free Auto-build gang sheet builder takes all the guesswork out of it. Just upload your artwork, and the tool helps you arrange and optimize the layout to fit as many designs as possible. It’s the easiest, most cost-effective way to guarantee you’re getting the absolute best value.

What Is the Best File Format for T Shirt Printing?

For the sharpest possible prints, a vector file like an AI, EPS, or SVG is always the gold standard. If you’re working with raster images (like photos), your best bet is a high-resolution PNG with a transparent background, saved at 300 DPI (dots per inch).

This ensures your final print is crisp, clean, and free of any blurry or pixelated edges. If you need a hand getting your art prepped, we also offer professional vectorization services to make sure your files are 100% print-ready.

Ready to bring your ideas to life with prints that pop? At Lion DTF Transfers, we deliver vibrant, durable DTF prints that make your designs stand out from the crowd.