The biggest difference between DTF and DTG printing boils down to one simple thing: how the ink gets onto the shirt.

Think of DTG (Direct-to-Garment) like a high-tech inkjet printer made just for clothes. It sprays the ink directly into the cotton fibers, making the design feel super soft and breathable—almost like it’s part of the fabric itself.

DTF (Direct-to-Film), on the other hand, is a two-step dance. First, we print your design onto a special film. Then, we use a heat press to transfer that entire design onto the garment. This creates a vibrant, durable layer that sits on top of the fabric, and it works on just about anything.

Decoding the Core Differences

Picking the right way to decorate your apparel is a huge decision, whether you're a growing brand, a hobbyist, or a full-blown print shop. Both DTF and DTG can produce incredible, full-color designs, but they get there in completely different ways, each with its own set of strengths. Getting a handle on these foundational differences is the key to figuring out which method is right for your projects and your business.

DTG printing is famous for that incredibly soft finish. Since the water-based inks soak right into the fabric, you can’t really feel the print. It’s just… part of the shirt. But there’s a catch: this process really only works its magic on 100% cotton and needs a pre-treatment spray to make sure the ink sticks and looks bright, especially on dark shirts.

This is where DTF printing really shines—it’s all about versatility. The design is printed onto a transfer film, dusted with an adhesive powder, and then cured. Once that transfer is made, you can press it onto a massive range of materials, including:

- Cotton

- Polyester and tricky poly-blends

- Nylon

- Leather

- Even hard stuff like wood

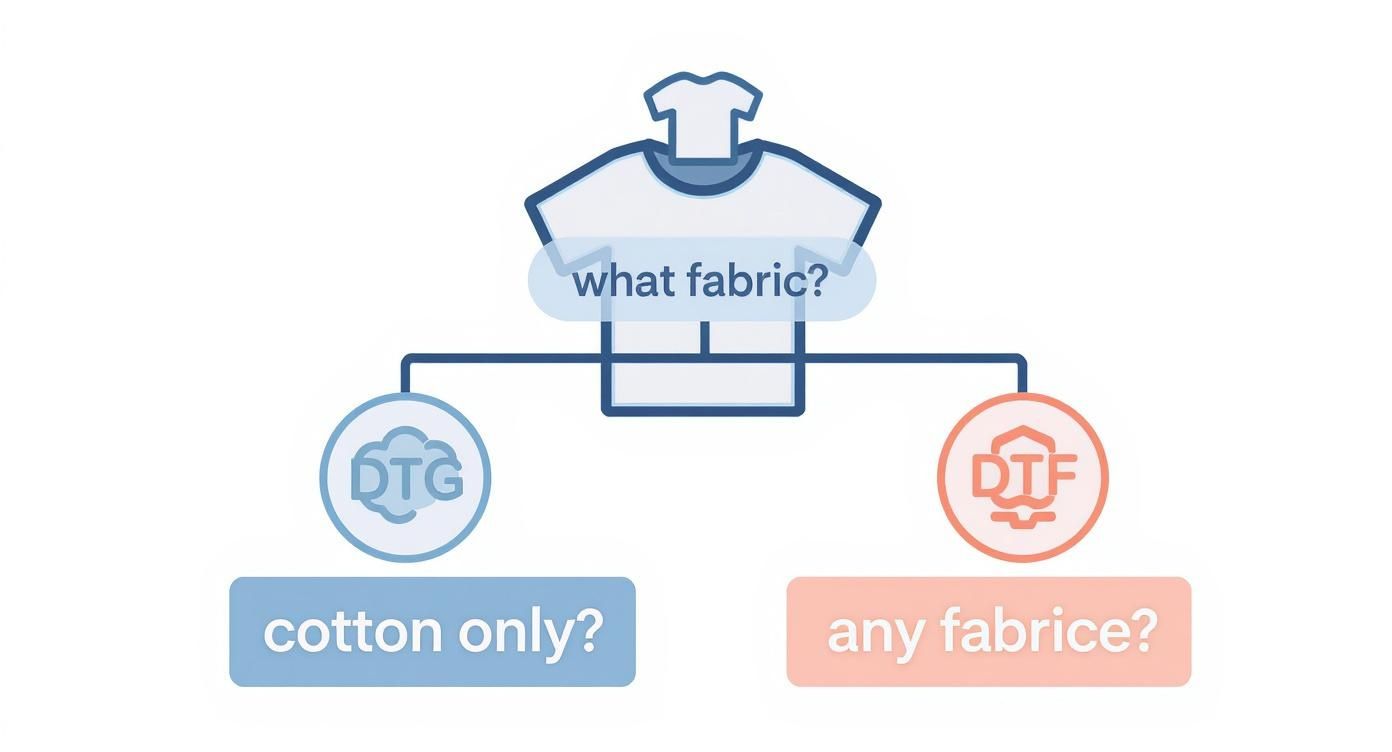

This little graphic really simplifies the main thing you need to think about: your fabric.

As you can see, the choice often starts and ends with what you're printing on. DTF just opens up way more doors for creativity and lets you build a more diverse product line. If you want to go deeper, you can explore the different DTF printing solutions out there for all sorts of jobs.

At a Glance DTF vs DTG Comparison

To make it even simpler, here’s a quick-and-dirty comparison table. It breaks down the most important differences between DTF and DTG so you can see how they stack up side-by-side.

| Feature | DTF (Direct-to-Film) | DTG (Direct-to-Garment) |

|---|---|---|

| Fabric Compatibility | Excellent (Cotton, polyester, blends, leather, nylon) | Limited (Best on 100% cotton or high-cotton blends) |

| Print Feel | Sits on top of the fabric, smooth plastic-like feel | Soft and breathable, integrated into the fabric |

| Vibrancy | Extremely vibrant on all fabric colors | Vibrant on light cotton, requires underbase on darks |

| Durability | Highly durable, excellent stretch and wash resistance | Good, but can fade over time with repeated washes |

| Workflow | Print transfers in batches for later application | Print on-demand, directly onto one garment at a time |

This table gives you the 30,000-foot view. DTF is your go-to for flexibility and punchy colors on any material, while DTG is the champ for that soft, premium feel on cotton.

When it comes to picking a print method, how the final design looks and feels is a huge deal. This is where you’ll spot the biggest differences between DTF and DTG. The way the ink hits the fabric completely changes the vibe, from the texture under your fingertips to how the colors pop.

Getting these distinctions right is key to matching the print method to your product.

The Feel: Soft and Seamless vs. Smooth and Bold

DTG printing is known for its incredibly soft hand-feel. Because the water-based inks are shot right into the cotton fibers, the finished print feels like it’s part of the shirt. You almost can’t feel it. It’s breathable and flexible, making it the go-to for high-end clothing, fashion lines, and baby apparel where a soft touch is everything.

A DTF transfer, on the other hand, sits right on top of the fabric. We print the design onto a special film, back it with an adhesive powder, and then heat-press it onto the garment. This whole process creates a smooth, slightly raised layer that you can definitely feel—most people describe it as having a soft, flexible, almost rubbery texture. If you want the full scoop, we break down exactly what DTF transfers feel like in our detailed guide.

Color Vibrancy: It’s All About the Underbase

The secret sauce for getting bright, screaming colors on dark shirts is the white under base. For both methods, this is a layer of white ink that goes down first, preventing the colors from getting swallowed up by the dark fabric. But how that underbase is applied makes all the difference.

With DTG, white ink is sprayed directly onto the pre-treated cotton. It works, but the fabric's own texture can sometimes peek through, and how vibrant it looks depends heavily on the quality of the pre-treatment and the garment itself. The colors are bright, but they’re still part of the fabric’s surface.

DTF flips the script. The white underbase is applied to the film, not the fabric. This creates a perfectly smooth, solid white foundation for the colors.

This is exactly why DTF prints often look more vibrant and saturated than DTG, especially on dark polyester or blends. The colors aren’t fighting with the fabric texture—they’re sitting on a perfect white canvas, which gives them maximum punch.

Real-World Scenarios: DTF vs. DTG

Let’s put this into practice. Here are two super common jobs and which method wins.

Scenario 1: A Bold Logo on a Sports Jersey

- Method of Choice: DTF Printing

- Why it Works: A polyester jersey is a total non-starter for standard DTG. DTF is the hero here, creating a razor-sharp logo with killer vibrant colors that pop against the synthetic material. The transfer is flexible and tough, so it’ll stretch and move with an athlete without cracking.

Scenario 2: A Detailed Photograph on a White Cotton Tee

- Method of Choice: DTG Printing

- Why it Works: Got a photorealistic image for a classic white cotton t-shirt? DTG is your best friend. The ink will soak right into the soft cotton, perfectly reproducing all the subtle gradients and fine details with a finish you literally can’t feel. It’s the definition of a retail-quality garment.

In the end, it’s a balancing act between texture, vibrancy, and the material you’re printing on. DTG gives you that unmatched soft feel on cotton, but DTF delivers a superior color punch on a much, much wider range of fabrics.

Print Durability: How Do They Hold Up in the Wash?

A killer design means nothing if it cracks, peels, or fades after a few trips through the laundry. When you're weighing DTF vs. DTG, durability is where the rubber really meets the road, directly impacting how happy your customers are and how long your products last.

The secret to their performance lies in how they're made. DTF prints are essentially a super-flexible, tough layer of ink and adhesive that gets heat-pressed onto the surface of the fabric. This creates a solid, resilient barrier that stands up surprisingly well to the abuse of a washing machine.

Because of this, DTF has a clear edge for stuff that needs to be tough—think workwear, sports gear, and kids' clothes. The print stretches and moves with the fabric, which is why you see far less cracking and peeling over time.

The DTF Advantage in Wash Tests

When it comes to wash performance, DTF transfers are the undisputed champ. That adhesive bond is engineered for the long haul. In real-world testing, a quality DTF print can easily handle 50-100+ wash cycles without losing its punch. The colors stay bright and the design remains solid.

This makes DTF a no-brainer for:

- Team Sports Jerseys: It can take all the stretching, sweat, and aggressive washing you can throw at it.

- Company Work Uniforms: It holds up to the daily grind and even industrial laundering.

- Merch for Active Brands: Your logos and designs will still look awesome long after the sale.

If you want to get into the nitty-gritty of what makes these prints so tough, check out our guide on how long DTF transfers last for a full breakdown.

DTG Durability: Good, But With a Catch

DTG prints are also durable, but their lifespan is a bit more of a moving target. Since the ink soaks into the cotton fibers, its longevity is directly tied to the life of the fabric. As those fibers start to fray from repeated washing, the print can start to fade along with it.

A DTG print's durability really hangs on two things: pre-treatment and curing. Mess up the pre-treatment, and the ink won't bond right. Cure it at the wrong temp or for too little time, and the ink can wash out in a heartbeat. When it's done perfectly, a DTG print holds up well, but any slip-up in the process can lead to a faded design way too soon.

Look, a perfectly made DTG print feels incredibly soft, but DTF just delivers a more consistent and reliable result when it comes to long-term toughness. That sealed, protective layer of a DTF transfer is simply better built to handle friction and washing again and again.

How to Make Your Prints Last

No matter which method you choose, a little TLC goes a long way. To get the most life out of any custom garment, stick to these simple rules:

- Wash Inside Out: This is huge. It protects the print from getting scraped up by other clothes or the inside of your machine.

- Use Cold Water: Hot water is the enemy. It breaks down both the fabric and the print way faster.

- Tumble Dry Low or Hang Dry: High heat will wreck a custom print. If you can, just hang it up to dry. It's the safest bet.

At the end of the day, if you’re a business that needs vibrant prints that can truly take a beating, DTF is the clear winner. And if you're lining up a bunch of different designs for various products, our Auto-build gang sheet builder makes it dead simple and cost-effective to get it done, saving you money without ever sacrificing that top-tier durability your customers demand.

Where Can I Put My Print? Breaking Down Fabric Compatibility

Let's get straight to it: one of the biggest deal-breakers between DTF and DTG is what you can actually print on. This isn't just a small detail—it completely shapes what products you can sell and who you can sell them to. Honestly, for many print shops and clothing brands, this single factor ends the debate right then and there.

Think of it this way: one method is a jack-of-all-trades, while the other is a specialist. DTG is an absolute master of its craft, but only in a very specific niche.

DTF Printing: The All-Rounder

The killer feature of DTF printing is its incredible versatility. Because we print the design onto a film first and then press it onto the garment with an adhesive, it can stick to almost anything. There's no need for special fabric treatments or chemistry.

This simple, indirect approach blows past the usual printing limits. It doesn't care if the material is cotton, a synthetic performance fabric, or a tricky blend. The DTF transfer sits right on top of the fabric, giving you a bright, solid print every single time.

This makes DTF the clear winner for any business that wants to offer a wide range of products. You can confidently print on:

- 100% Cotton and Blends: Your standard tees, 50/50 hoodies, all the classics.

- Polyester: The go-to for athletic wear, team jerseys, and gym clothes.

- Nylon: Perfect for windbreakers, bags, and outdoor gear.

- Leather and Faux Leather: Unlocks a whole world of custom accessories.

- Denim, Canvas, and More: Think tote bags, aprons, and other unique items.

Imagine printing one logo and being able to apply it to a dozen different products. That's a massive win for efficiency and cost effectiveness. Our Auto-build gang sheet builder takes this even further, letting you easily cram all sorts of designs onto one sheet to slash your material waste and lower your cost per print.

The DTG Printing Niche: A Cotton Specialist

DTG, on the other hand, is a cotton purist. The water-based inks it uses are made to soak into and bond with natural fibers. That's how DTG gets that super soft, breathable feel—the ink literally becomes part of the shirt.

But this specialization is also its biggest weakness. DTG inks just can't get a good grip on synthetic materials like polyester. The ink tends to just sit on the surface, looking splotchy and faded, and it definitely won't survive the wash.

DTF’s ability to work flawlessly on cotton, polyester, nylon, and blends is a strategic advantage. It allows a brand to expand its product line beyond basic t-shirts into high-margin items like performance wear, outerwear, and accessories without changing its printing process.

Sure, there are some pricey pre-treatments out there that claim to make DTG work on polyester, but the results are often hit-or-miss. It adds a ton of complexity and cost to your workflow. For most shops, DTG is strictly for 100% cotton or blends with a very high cotton count. Trying to print on dark polyester with DTG is a recipe for a headache and an unhappy customer.

This makes the DTF vs. DTG choice pretty simple. If your business plan involves custom jerseys for sports teams, polyester polos for corporate events, or unique items made from weird fabrics, DTF isn't just a better choice—it's really your only practical one. Being able to say "yes" to almost any fabric request is how you grow a business.

Understanding the True Costs and Economics

When you're comparing DTF and DTG printing, the conversation always lands on the bottom line. But the true cost is way more than just ink and blank tees; you've got to factor in equipment, maintenance, all the little consumables, and labor. Getting a handle on these numbers is key to making a smart investment for your shop.

Right off the bat, the upfront investment shows a massive difference between the two. A complete DTF system—printer, powder shaker, and curing oven—is a serious capital outlay. You're often looking at tens of thousands of dollars for a setup that won't let you down.

On the flip side, an entry-level DTG printer might look cheaper at first glance. But don't be fooled. The industrial-grade DTG machines built for real production volume can easily cost more than a DTF setup, and they're notorious for high-maintenance printheads that clog if you look at them wrong.

Breaking Down the Per-Print Costs

Beyond the big machines, the per-print costs tell the real story. This is where DTF often pulls ahead with lower prices on consumables. The ink, film, and adhesive powder you need for a DTF transfer are generally cheaper per print than the specialized ink and mandatory pre-treatment spray required for every single DTG garment.

This cost gap gets even wider when you're printing on dark shirts. DTG needs a thick, expensive layer of white ink as a base to make colors pop on dark cotton. DTF, however, applies a much more efficient white layer directly onto the film, which almost always means a lower ink cost for the same vibrant design.

A Smarter Alternative to Owning the Equipment

Look, for a lot of businesses, the huge upfront cost and constant upkeep of either system is a major roadblock. This is where you can make a strategic pivot to a powerful, budget-friendly alternative: just use a DTF transfer service instead of buying the whole setup yourself.

By ordering ready-to-press DTF transfers, you completely sidestep the massive initial investment, the painful learning curve, and the non-stop headache of machine maintenance. This flips a huge capital expense into a predictable, scalable operational cost.

This model gives you access to professional-grade prints whenever you need them, and you only pay for what you use. It's the perfect solution for small shops, startups, and even bigger operations looking to add new products without the financial risk or operational drain of new machinery. You get all the perks of DTF's versatility and toughness with none of the ownership headaches.

Maximize Your Savings with Gang Sheets

To make this approach even more of a no-brainer, you have to use gang sheets. A gang sheet is just a big sheet of transfer film packed with multiple designs, which absolutely tanks your cost per print. Instead of ordering one design at a time, you can cram logos, sleeve hits, and all sorts of graphics onto a single sheet.

This is exactly where our Auto-build gang sheet builder is a total game-changer. It makes the whole process ridiculously easy and cost-effective. Just upload your designs, and it automatically arranges them to use every last square inch of film. This slashes waste and drives your per-print cost way down, making professional-quality custom gear more profitable than ever. It's a scalable way for any business to get in the game and grow.

Workflow Efficiency and Production Speed

When you’re weighing DTF vs. DTG, you really have to look at how each one fits into your workday. The end-to-end process for each is wildly different, and that directly impacts how fast you can get a finished shirt out the door. The best choice really depends on if you're a one-shirt-at-a-time kind of shop or if you're prepping for a big run.

The DTG workflow is very linear and all about the garment. It's a one-by-one process, which is why it shines for single, on-demand orders. You have to pretreat the garment, heat press it dry, load it onto the printer, print the design, and then cure the final product.

This step-by-step method works great when a customer wants just one unique t-shirt. But try to do a larger batch, and you'll see the bottleneck pretty quickly. Each shirt ties up the entire production line from start to finish.

The DTF Production Advantage

DTF, on the other hand, is built for batching. The whole process is flipped on its head. You start by printing your designs onto a transfer film, apply an adhesive powder to the ink, and cure it. Only after all that is done do you even need a garment, and that final step is just a quick heat press application.

This is the secret sauce of DTF: separating the printing from the pressing. It lets you "print ahead," breaking the link between the time-consuming print job and the final sale.

This "print and store" model is a total game-changer for production speed. You can print and stock up on your most popular designs. When an order comes in, you just grab a transfer and press it. Fulfillment becomes a simple, lightning-fast process.

Take Your Workflow to the Next Level

Batch-printing your own transfers is a huge leap in efficiency, but you can streamline things even more by outsourcing the tricky parts. Ordering pre-made gang sheets from a service like ours completely removes the printing, powdering, and curing from your shop. You basically transform your business from a print manufacturer into a high-speed apparel decorator.

Your workflow becomes dead simple:

- Get an order.

- Grab a pre-made DTF transfer.

- Heat press it onto the blank shirt.

This setup takes up minimal space, creates no mess with ink or powder, and is way easier to train new employees on. You can crank out dozens, even hundreds, of orders with just a heat press and your inventory of transfers. It's not just faster; it's also a whole lot cheaper, especially when you pack your sheets tight.

Our Auto-build gang sheet builder was made for exactly this. It helps you cram as many designs as possible onto a single sheet with incredible ease, which drops your cost per image through the floor. It makes building a library of press-ready graphics almost effortless. By focusing only on that final, quick heat press step, you can massively boost your production speed and scale your business without sinking cash into a bunch of in-house printing gear.

Common Questions About DTF and DTG Printing

Got a few lingering questions? Perfect. When you're trying to nail down the right print method, the details really matter. Let's clear up some of the most common questions that pop up when comparing DTF vs. DTG printing.

Which Method Is Better for a Small Business Starting Out?

For anyone just jumping into the apparel game, starting with a DTF transfer service is almost always the smarter move. It lets you skip the massive upfront cost, the steep learning curve, and the non-stop maintenance that comes with owning a DTG printer.

By ordering ready-to-press DTF transfers, you can put all your energy into creating great designs and connecting with customers. You get consistent, top-shelf results on a massive range of products without the headaches. It's a low-risk, high-versatility way to get your business off the ground and scale up when you're ready. For the ultimate ease of use and cost effectiveness, our Auto-build gang sheet builder streamlines the entire ordering process.

Can I Print on Hats and Other Non-Flat Items?

Absolutely, and this is where DTF really pulls ahead. Since you’re just applying a flexible transfer with a heat press, you can use different-sized platens to get your designs onto all kinds of contoured items—hats, sleeves, bags, you name it.

DTG, on the other hand, is stuck in the flat world. It needs a perfectly flat surface that can be loaded onto the printer's platen, which means it’s a no-go for most accessories and anything that isn't a standard flat garment.

DTF's ability to decorate irregularly shaped objects is a game-changer. It opens the door to creating a whole ecosystem of branded merch, from t-shirts to headwear, all using the same killer print method.

How Does the Environmental Impact Compare?

Both methods have their pros and cons environmentally. DTG printing uses water-based inks and applies them right to the garment, which cuts down on some waste, but you still have to account for the chemical pre-treatment sprays.

DTF involves plastic films and adhesive powders, which can create more consumable waste. But the industry is making moves toward recyclable films and more eco-friendly powders. A huge part of minimizing that footprint comes down to efficiency. Using a tool like our Auto-build gang sheet builder is key—it lets you pack as many designs as possible onto a single film with incredible ease, which slashes waste and makes every print run more cost-effective.

Ready to unlock some serious versatility and durability for your custom apparel? At Lion DTF Transfers, we make getting pro-level prints unbelievably simple. Use our powerful online tools to design your perfect transfer and see the difference for yourself. Build Your Custom Gang Sheet Now

Article created using Outrank