Picture this: you're running an online store packed with unique, custom-designed products, but you never have to touch a single piece of inventory or make a run to the post office. That’s the magic of the print on demand business model. It's a system where you sell your products first, and only after a customer pays are they actually created and shipped. This simple flip completely removes the massive financial risk that comes with traditional retail.

Understanding the Print On Demand Business Model

Think of the print on demand model as having a massive, automated digital factory at your beck and call. Instead of gambling on buying hundreds of t-shirts upfront and just hoping they sell, you create a design, upload it to a product in your online store, and let your partner—the print provider—take care of the rest.

When a customer falls in love with your custom hoodie or tote bag and clicks "buy," that order gets zapped directly to your production partner. From there, they print your design onto a blank product, package it up, and ship it straight to your customer's doorstep, all under your brand's name. You get to be the creative director and marketer; they act as your silent, behind-the-scenes production crew. It's a clean, simple workflow that’s changing the game for creators and entrepreneurs.

The Key Players in a POD Partnership

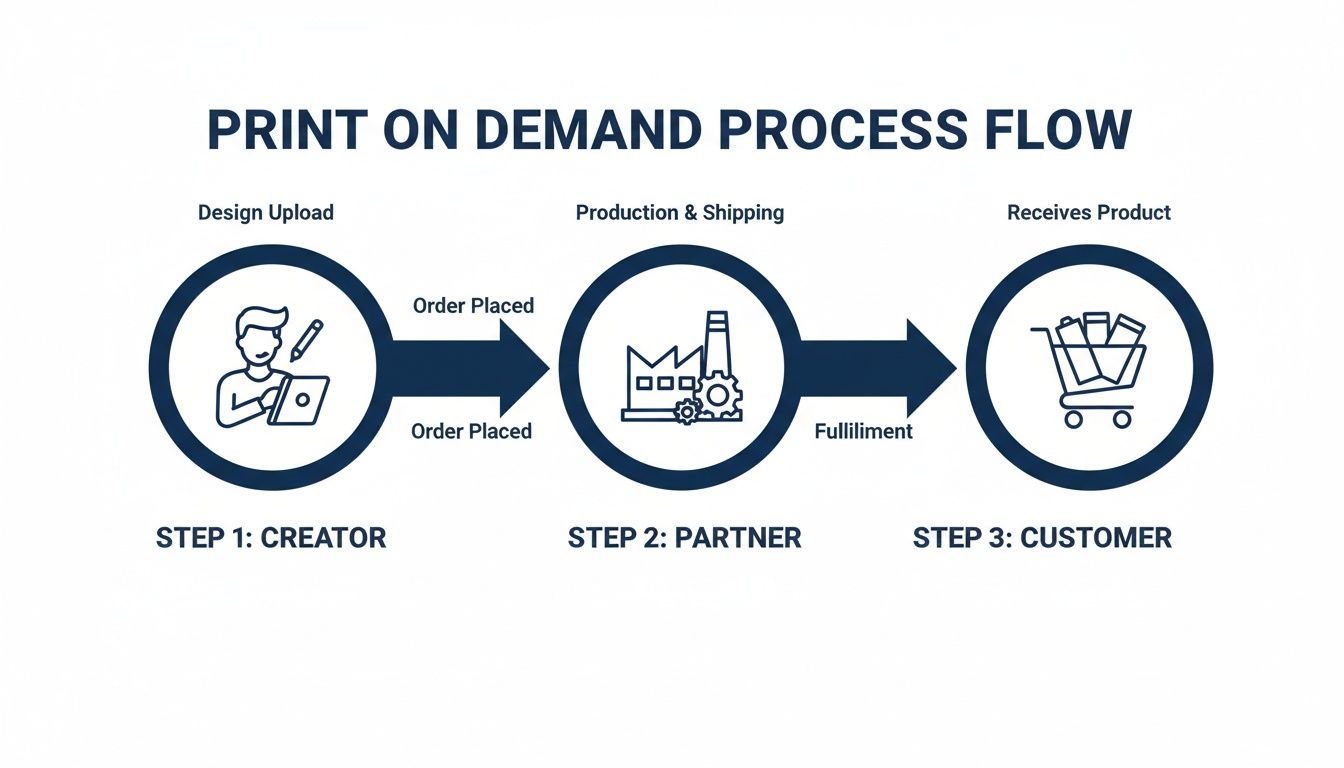

The entire system hums along thanks to a simple, three-part relationship. Getting a handle on these roles is the first step to seeing exactly where you fit in.

- You (The Creator): Your job is all about creating killer designs, building a storefront that tells your brand’s story, and marketing your products to the right people. You’re in full control of the brand, the designs, and the final price.

- Your POD Partner (The Producer): This is the company that handles all the physical stuff. They source the blank products, manage the high-tech printing equipment, and deal with all the packaging and shipping logistics so you don't have to.

- Your Customer (The Buyer): They find your store, connect with your unique designs, and make a purchase. What they receive is a high-quality product with your branding on it, often completely unaware that a third-party partner ever touched it.

This "sell first, create later" approach has completely reshaped e-commerce. It allows anyone with a creative spark to launch a real business with minimal startup costs and virtually no inventory risk, letting them pour their energy into design and community instead of logistics.

This efficiency has pushed the POD market from a small niche into a full-blown industry. Market research firms estimated the global market was already worth over $10 billion in 2025 and project it will explode to nearly $57.5 billion by 2033—a clear sign of its incredible growth.

For apparel brands, a hugely popular production method used by POD partners is Direct to Film (DTF) printing, which is known for its ridiculously vibrant colors and tough durability. To get a better sense of how the tech works, check out our guide on what DTF printing is and how it creates those pro-level garments.

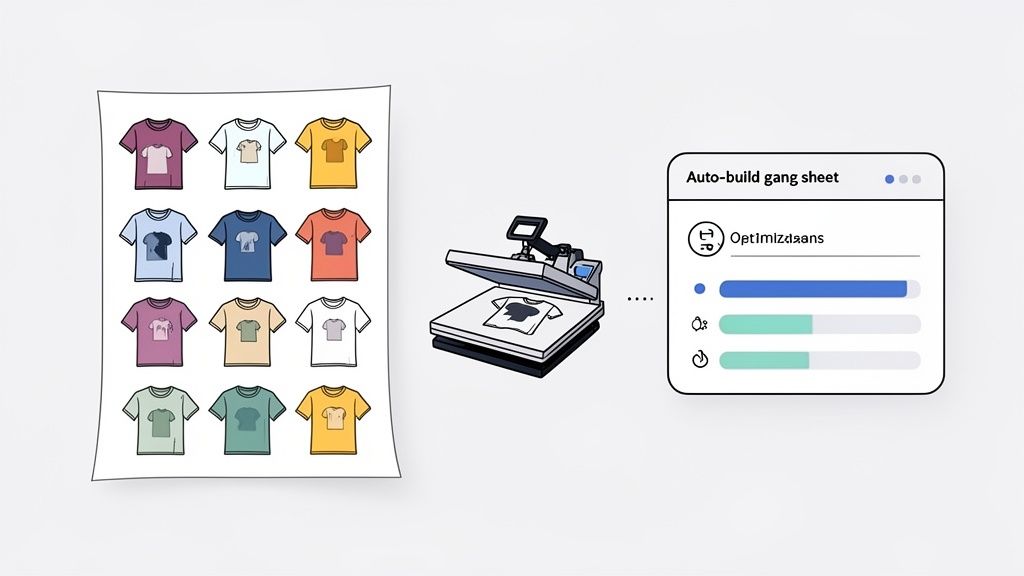

As you grow, you can even use DTF transfers to bring some production in-house. By using our Auto-build gang sheet builder, you can arrange a bunch of your designs onto a single sheet. Its ease of use and cost-effectiveness make it incredibly simple to print your bestsellers on your own terms.

How the POD Supply Chain Actually Works

So, what really goes on behind the curtain when a customer clicks "buy" on your store? The magic of the print on demand business model is its automated, hands-off supply chain. This is the engine that turns your digital design into a real product that lands on your customer's doorstep—all without you ever touching a single piece of inventory.

Let's walk through the journey of a single order, using a custom t-shirt as our example. This simple workflow is what powers your entire operation, freeing you up to focus on what you do best: designing and marketing.

From Click to Customer: The POD Journey

Think of the process as a seamless digital handshake between your online store and your production partner. Every step is triggered automatically, so you don't have to lift a finger.

- A Customer Places an Order: A shopper finds your awesome t-shirt design on your Shopify or Etsy store and makes a purchase. The payment gets processed, and the order is officially logged.

- The Order is Sent to Your Partner: Instantly, your e-commerce platform sends all the critical details—the specific design file, the t-shirt size and color, and the customer's shipping address—directly to your integrated POD provider.

- The Product is Created: Your POD partner’s fulfillment center gets the notification and gets to work. They pull a blank t-shirt from their warehouse stock and use their printing equipment to bring your design to life on the fabric.

- Packaging and Shipping: Once the tee is printed and passes a quality check, it’s packaged up. It then gets shipped directly to your customer, often with your own branding on the return label to complete the white-label experience.

This infographic shows just how linear and straightforward this flow is between you (the creator), your partner, and the customer.

The key takeaway here is that you, the creator, stay completely detached from the physical side of things. You're the creative and marketing force, not a warehouse manager.

Optimizing Your Fulfillment Workflow

This hands-off approach is the core value of POD. While your partner handles the printing, packing, and shipping, you get to focus on the tasks that actually grow your business, like dreaming up new designs, connecting with your audience, and running ad campaigns. To keep things running smoothly, brushing up on ecommerce shipping best practices is a smart move for optimizing that final, crucial step of the journey.

The real beauty of this system is its scalability. Whether you sell one shirt or a hundred in a day, the process just works. It handles the volume without piling any extra logistical work onto your plate.

As your brand gets bigger, you’ll probably start looking for ways to squeeze a bit more profit out of your best-selling items. This is where more advanced tactics come into play, like using Direct to Film (DTF) transfers for your most popular designs.

To get the most bang for your buck, you can learn how to build a DTF gang sheet, which lets you group a bunch of designs onto a single sheet for printing. By using our Auto-build gang sheet builder, you can easily arrange your artwork to maximize every inch of space, making it an incredibly cost-effective way to produce your top sellers. It's a great strategy for putting more control—and profit—back in your pocket.

Calculating Your POD Costs and Profit Margins

Alright, let's talk numbers. This is where your creative side hustle starts looking like a real, sustainable business. How do you actually make money with print on demand when you're not holding any inventory? It all boils down to understanding your costs and pricing your products smartly to protect your profit on every single sale.

While you get to skip the massive upfront cost of buying products in bulk, each item you sell still has a few costs baked into it. These get deducted from the price your customer pays, and whatever is left over is yours to keep. The goal is to set a retail price that covers everything and still leaves a healthy chunk of change for you.

Breaking Down the Core Costs

Every time a customer hits that "buy" button, a chain reaction of costs kicks in. Getting a handle on these numbers is the first step toward setting a price that actually makes you money.

- Product Base Cost: This is what your POD partner charges you for the blank item—the t-shirt, mug, or poster before your art goes on it. The cost can change based on the item's quality, brand, and even size.

- Printing Fee: This is the charge for actually applying your design. It often depends on the print method and how complex your design is. Think one-sided versus a front-and-back print.

- Shipping Costs: This covers packing the item up and sending it straight to your customer. The price is usually based on the product type, its weight, and where it's headed.

- Marketplace & Transaction Fees: Your sales platform, whether it's Shopify or Etsy, will skim a small percentage off each sale. On top of that, payment processors like PayPal or Stripe take their cut, which is typically around 2.9% + $0.30 per transaction.

When you add all these up, you get your "Cost of Goods Sold" (COGS) for that one item. From there, the math is simple: Retail Price - COGS = Your Profit.

A Real-World Profit Calculation

To see how this works in practice, let's break down the costs for a single print on demand t-shirt. This kind of calculation is essential for figuring out if your pricing strategy is on the right track.

Sample Product Profit Margin Calculation

| Item | Cost/Price | Notes |

|---|---|---|

| Retail Price | $30.00 | The price you list in your store. |

| Blank T-Shirt Cost | -$10.00 | The base cost from your supplier. |

| Printing Fee (Front) | -$5.00 | The charge for printing your design. |

| Shipping Cost | -$4.50 | The fee to ship to the customer. |

| Platform/Payment Fee | -$1.50 | An estimate of transaction fees (~5%). |

| Total Costs | $21.00 | The total cost to get the order fulfilled. |

| Your Final Profit | $9.00 | The money you actually earn from the sale. |

In this example, your profit margin comes out to 30% ($9 profit / $30 retail price). Running these numbers for every product is non-negotiable. Tools like a Shopify Profit Margin Calculator can make this process way easier and help you keep a close eye on your business's financial health.

Choosing the Right Pricing Strategy

Sure, the per-item cost in POD is higher than buying in bulk, but that's the trade-off for zero inventory risk. Apparel is king in this space, and most successful sellers aim for a profit margin somewhere between 20–40% after all the costs are paid.

The key is setting a price that reflects the unique value of your designs, not just the cost of production. Your creativity is the real product customers are buying.

Want to squeeze more profit out of each sale? It's time to get smarter with fulfillment. For instance, using our Auto-build gang sheet builder lets you easily arrange multiple designs on a single film, which can seriously slash your printing costs, especially for your top-selling designs. Its cost-effectiveness is a major advantage for scaling brands.

You can learn more about how different printing methods stack up by comparing the benefits of DTF printing vs DTG. This is the kind of behind-the-scenes efficiency that separates the hobbyists from the truly profitable brands.

Launching Your First Print On Demand Store

Alright, this is the exciting part. Moving from a cool idea to a live store is where the print on demand business model really comes to life. It’s the moment your designs become actual products people can browse, buy, and love. Getting there involves a few key decisions, from figuring out who you're selling to, to picking the right platform to showcase your work.

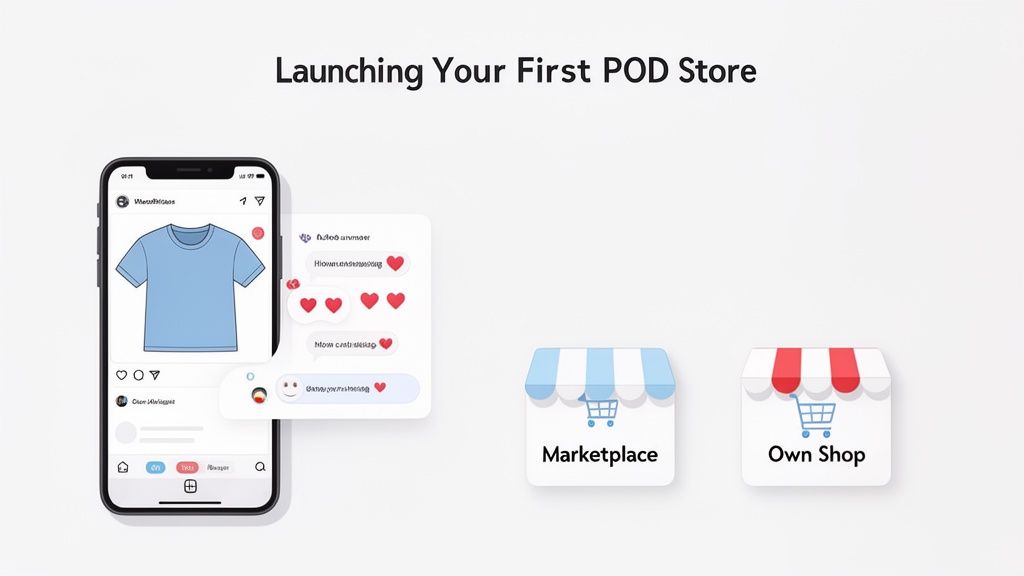

Your first step isn't about the product; it’s about the person. In a crowded market, success comes from finding a specific niche. Don't just make generic t-shirts. Instead, zero in on a community you genuinely get—maybe it's dachshund owners, vintage sci-fi fans, or nurses with a dark sense of humor.

When you know exactly who you're talking to, you can create designs that hit the mark. This focused approach makes marketing a whole lot easier and helps you build a real brand with loyal fans.

Find Your Niche and Validate Your Designs

Before you build out an entire product catalog, test the waters. You don't even need a live store to figure out if you've got a winner. Create some professional-looking mockups—basically, digital previews of your designs on shirts, hats, or mugs—and get them in front of your target audience on social media.

Head to where your community hangs out. Use Instagram polls or post in a relevant Facebook group and just ask for feedback. Simple questions like, "Which color combo works best?" or "Hoodie or tote bag for this design?" will give you incredible insight. This validation step is super low-risk and makes sure you're putting your energy into products people actually want.

There's an old marketing idea called the "Rule of Seven," which says a potential customer needs to see your brand at least seven times before they'll buy. Sharing mockups and behind-the-scenes content isn't just for validation; it's the start of building that all-important brand recognition.

Choose Your Sales Channel

Once you have a few designs that people are excited about, you need a place to sell them. In the POD world, you have two main options, and they each have their own pros and cons.

- Marketplaces like Etsy: The huge advantage here is the built-in traffic. Millions of people are already on Etsy actively looking for unique stuff. This can get you seen right away without a big marketing spend. The downside? Less control over your brand and a lot more direct competition on the platform.

- Your Own Store with Shopify: Using a platform like Shopify means you're building your own turf. You get total control over your website's look, the customer journey, and all your data. It takes more work to drive traffic, but the long-term payoff is building a scalable, independent brand that's truly yours.

Which one is right for you? It really depends on your goals. Etsy is a fantastic launching pad to test ideas quickly. Shopify is the move for building a long-term business asset.

Integrate Your POD Provider and Go Live

After you've picked your sales channel, the last piece of the puzzle is connecting it to a POD provider. Services like Printful or Printify integrate directly with platforms like Etsy and Shopify, handling all the backend work for you. Once connected, you just upload your designs, choose which products to put them on, and push them live to your storefront.

When you're writing your product listings, focus on great descriptions and use high-quality mockup photos that let customers picture the item in their own lives. Be upfront about production and shipping times in your store policies to manage expectations right from the start.

As your store grows, you'll want to find ways to boost your profit margins. For your best-selling designs, switching to Direct to Film (DTF) transfers can seriously cut your per-item costs. Our Auto-build gang sheet builder makes this transition seamless. Its ease of use and cost-effectiveness let you pack multiple designs onto a single sheet to maximize efficiency. This is how you take your print on demand business model from a side hustle to a seriously profitable operation.

Scaling Your Business with Smart Fulfillment

Once your store finds its groove and orders start trickling in consistently, the game changes. The initial buzz of launching fades, and a new challenge emerges: how do you scale up without your profit margins getting squeezed? Moving from a few sales here and there to a reliable revenue stream demands a smarter approach to both marketing and, maybe more importantly, your fulfillment.

While getting sustainable traffic to your store is one piece of the puzzle, the real secret to long-term profitability is in your operations. The standard print on demand business model is unbeatable for getting started, but once you know what sells, a hybrid approach can seriously boost what you earn on every single sale. This is where you level up from pure POD to a more hands-on, high-margin game plan.

The Hybrid Model: From POD to In-House Finishing

Let's say you have three t-shirt designs that are flying off the virtual shelves week after week. In a typical POD setup, you're paying a premium to have each one printed and shipped out one by one. But what if you could slash that cost per shirt by more than half? You can, by bringing production for those proven winners in-house with Direct to Film (DTF) transfers.

This hybrid model doesn't mean you ditch POD altogether. Far from it. You keep using it to test new designs, float creative ideas, and fulfill orders for your less popular items. But for your superstars, you order the designs as ready-to-press DTF transfers and apply them to blank garments yourself with a simple heat press.

This strategy introduces a tiny bit of inventory (the transfers and some blank tees), but in return, you get a massive jump in profit margin and total control over the quality of your final product.

Unlocking Profit with DTF Gang Sheets

Ordering individual DTF transfers is a good first step, but the real cost-saving magic comes from using gang sheets. A gang sheet is just a large sheet of transfer film where you can cram multiple designs together, which brings the cost per design way, way down. Instead of paying for each graphic on its own, you pay for the whole sheet and fill it with as many of your top-sellers as you can fit.

This is where getting efficient really matters. Manually trying to arrange designs to use every last square inch of a gang sheet can be a tedious, time-sucking task.

That's precisely why our Auto-build gang sheet builder is such a game-changer. It automatically and intelligently arranges your uploaded designs for maximum space efficiency, ensuring you get the absolute lowest cost per print. This ease of use makes the transition to in-house fulfillment simple and incredibly cost-effective.

This operational shift is a natural progression for successful apparel brands. It's no surprise that North America has historically been the biggest market for POD, making up about 36.2% of global revenue in 2024. The combination of strong e-commerce adoption and a hungry market for custom gear creates the perfect environment for sellers to scale with smart methods like DTF. You can dive deeper into the POD market size and regional trends to see just how big the opportunity is.

Comparing Fulfillment Models

Making the right call means understanding the trade-offs. Here’s a look at how sticking with the standard model stacks up against adopting a hybrid DTF approach for your bestsellers.

POD Fulfillment vs DTF Transfer Fulfillment

| Feature | Standard POD Model | DTF Transfer Model |

|---|---|---|

| Upfront Cost | Virtually zero; no inventory needed. | Moderate; requires transfers, blank shirts, and a heat press. |

| Profit Margin | Lower; typically 20-40% per item. | Higher; can easily exceed 60-70% per item. |

| Fulfillment Time | Slower; dependent on partner's production queue. | Faster; press and ship orders on the same day. |

| Inventory Risk | None; products are made only after a sale. | Low; only stock transfers and blanks for proven sellers. |

| Control | Limited; rely on partner for print quality and shipping. | Full control; manage quality, packaging, and speed. |

| Best For | New stores, testing designs, and niche products. | Scaling bestsellers and maximizing profit on popular items. |

By embracing this kind of smart fulfillment strategy, you're not just running a store anymore—you're evolving your business. You shift from being just a designer to a savvy operator who can strategically cut costs, speed up delivery, and build a more resilient and profitable brand for the long haul.

Your Action Plan for POD Success

So, there you have it. You now have the complete map to get a real ecommerce store off the ground using the print on demand model. The whole thing is built on low startup costs, zero inventory headaches, and total creative freedom. It’s one of the best ways to turn an idea into a legitimate, profitable brand.

If you take one thing away, it should be this: start with a niche you actually get. That focus is what lets you create designs that connect with a real audience, which makes your marketing a thousand times easier. A great design on the right product, shown to the right person—that's the simple formula for your first sale and every sale after that.

Your Path to Profitability

Once your brand starts getting some traction, your mindset has to shift from just making sales to maximizing the profit on every single one. This is the moment you go from being a beginner to a business owner. For your designs that consistently sell, moving from a pure POD setup to a hybrid approach using DTF transfers is how you unlock much better margins.

The POD entrepreneurs who really crush it understand that optimizing fulfillment is just as critical as creating a killer design. Real scale comes from making your operations as lean and profitable as possible.

Making that transition is way easier than you think. By ordering your most popular designs on Direct to Film transfers, you take back control of your production costs. Our Auto-build gang sheet builder was designed for exactly this purpose, making it incredibly easy to use and cost-effective. It automatically packs your designs onto the sheet to use every inch of space, guaranteeing you get the lowest possible price per print.

This is the last piece of the puzzle. With a clear niche, designs that people love, a smart marketing plan, and a dialed-in fulfillment strategy, you're ready to step into the world of e-commerce and build something that lasts.

Frequently Asked Questions

Jumping into the print on demand business model can feel like you're learning a new language. You're bound to have questions, especially in the beginning. Let's break down some of the most common ones to give you the clarity you need to get moving.

How Much Money Do I Need to Start?

This is where print on demand really shines. Since you're not buying stacks of t-shirts or mugs upfront, the biggest expense of traditional retail—inventory—is completely off the table.

Your main costs at the start are your e-commerce platform subscription (like Shopify) and maybe a design tool. Honestly, you can get a store up and running for less than $100, which covers initial fees and a custom domain. You can start small with marketing and let your ad spend grow with your sales.

Can I Use My Own Designs?

Absolutely! In fact, you should. The whole point of the print on demand business model is to bring your unique creative vision to life. That's how you build a brand that people actually connect with.

Just make sure your files are top-notch. To get a clean, professional-looking product, you need to provide high-quality artwork. That typically means saving your designs as high-resolution images—at least 300 DPI—in a format like PNG with a transparent background. This is non-negotiable for a crisp print.

Is the Print On Demand Market Too Saturated?

It's definitely competitive, but "too saturated" isn't the right way to look at it. There's always room for good ideas. Success comes down to finding your niche and building a real brand around it.

The secret is to stop being generic. Don't just make a "cat lover" shirt. Instead, why not target owners of a specific breed, like Maine Coons or Sphynx cats? Unique designs, focused marketing, and authentic branding are what will help you carve out your own profitable corner of the market.

How Do I Handle Returns and Customer Service?

Simple: you are the face of your business. All customer communication, questions, and support tickets come directly to you. Your POD provider, on the other hand, usually handles returns for things that are their fault, like printing errors, damaged items, or defective products.

You’ll need a crystal-clear return policy on your site. When a customer makes a mistake, like ordering the wrong size, that's generally on you to figure out, since your partner fulfilled the order correctly. Good communication is everything here. As you grow, you might bring your bestsellers in-house using DTF transfers, which gives you far more control over quality and service. Our Auto-build gang sheet builder makes this switch not only easy to use but incredibly cost-effective.

Ready to bring your creative vision to life with vibrant, durable prints? At Lion DTF Transfers, we make professional-quality printing accessible to everyone. Explore our easy-to-use gang sheet builder and premium DTF transfers today.