Direct-to-Film (DTF) printing is a modern way to customize apparel where designs are printed onto a special film, then transferred to fabric using a heat press. It’s a seriously versatile technique that delivers vibrant, full-color graphics on just about any material you can think of.

What Is DTF Printing Explained Simply

Imagine creating a high-tech, durable sticker made specifically for fabric. In a nutshell, that's what DTF printing does. Instead of printing ink directly onto a shirt, this process prints your design onto a special transparent sheet called a PET film.

Once printed, the film gets coated with a powdered adhesive and cured with heat. This simple step transforms your design into a ready-to-press transfer. The final move is using a heat press to permanently bond this "fabric sticker" onto the garment. Think of it like a professional temporary tattoo for your clothes—one that’s incredibly durable and flexible.

The Modern Way To Print On Anything

DTF has quickly become a go-to method for custom apparel creators, and for good reason. It breaks the old rules of fabric printing by offering a powerful mix of quality, versatility, and efficiency. This isn't your average DIY iron-on that peels after one wash; it's a professional-grade solution built to last.

Here's why it's catching on:

- Unmatched Fabric Versatility: DTF works on materials that other methods struggle with. It applies perfectly to cotton, polyester, tricky blends, nylon, leather, and more.

- Vibrant and Detailed Prints: The process allows for stunning, high-resolution graphics with a brilliant color spectrum, including crisp white ink on dark garments.

- Cost-Effective for Complex Designs: For small to medium runs with lots of colors, DTF is incredibly economical. You can combine multiple designs on a single sheet, which is made even easier with tools like our Auto-build gang sheet builder that helps maximize space and minimize cost.

The core idea behind DTF is simple: create a high-quality, ready-to-apply transfer that works on almost any fabric. This removes the limitations of printing directly onto challenging materials, opening up a world of creative possibilities for apparel.

This blend of flexibility and quality is why so many businesses are making the switch. Before we get into the step-by-step process, it helps to know what these transfers are made of and why they work so well. You can learn more about the components that make DTF transfers so durable in our detailed guide.

Your Step-by-Step Guide to the DTF Process

Ever wondered how a digital file on a screen becomes a vibrant, wearable design? With DTF printing, the journey is surprisingly direct. The process boils down to a few core stages, and understanding them demystifies how a simple piece of art becomes a professional-grade transfer ready for pressing.

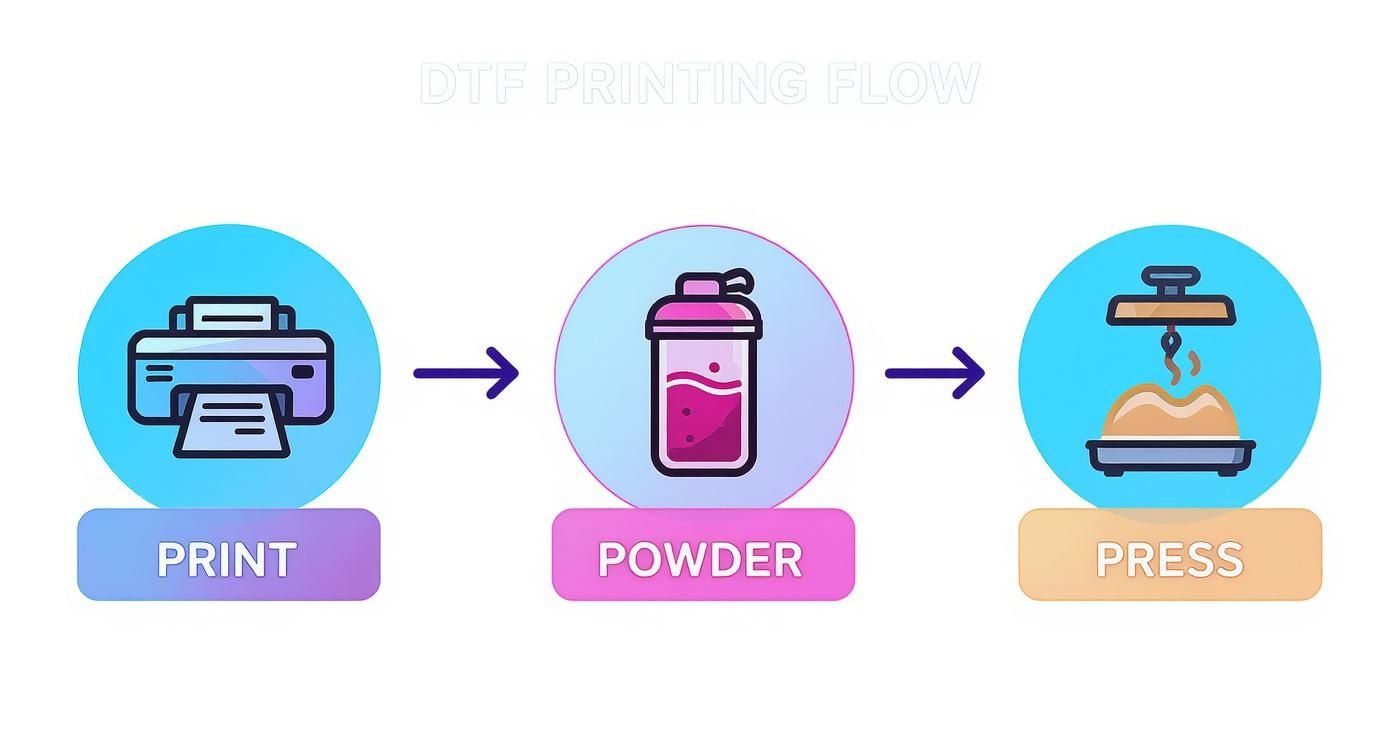

This infographic breaks down the essential three-step flow, from printing the design to the final heat press application.

As you can see, the workflow is logical: print, apply adhesive, and press. Each step builds on the last, setting the stage for a flawless final product. Let's break down exactly what happens at each point.

Step 1: Artwork Preparation and Printing

It all starts with your digital design. For the best results, you need a high-resolution file, usually a PNG with a transparent background. This is crucial because it ensures only your design gets printed—no unwanted white boxes or stray colors.

Once the file is prepped, it's sent to a specialized DTF printer. This isn't your average office machine; it’s built to handle specific DTF inks and PET film. The printer first lays down the full-color CMYK layer of your design onto the film. Then, in a second pass, it prints a perfectly aligned layer of white ink right on top. This white ink is the secret sauce—it acts as a base that makes your colors truly pop, especially on dark fabrics.

Step 2: Adhesive Application and Curing

This is where the real magic happens. While the ink is still wet on the PET film, it gets a generous coating of a fine, granular thermoplastic polyurethane (TPU) adhesive powder. The powder sticks only to the wet ink, creating an adhesive layer that perfectly mirrors your design.

Any extra powder is shaken off, leaving behind a crisp, clean outline. Next, the powdered film is sent through a curing oven or placed under a heat press that hovers just above the surface. This melts the adhesive and fuses it to the ink, turning the printed graphic into a stable, durable transfer that’s ready to press.

Step 3: Heat Pressing the Transfer

The final step is getting the transfer onto your garment. You’ll place the transfer on the fabric, and a heat press applies just the right amount of time, temperature, and pressure. A typical setting is around 240-280°F for about 10 seconds.

The combination of heat and firm pressure activates that cured adhesive, permanently bonding the ink layer into the fabric's fibers. This creates a bond that’s both incredibly strong and flexible, allowing it to move with the fabric instead of sitting stiffly on top.

Once pressed, the film is peeled away, leaving only your vibrant, soft-to-the-touch design behind.

For those looking to create multiple designs efficiently, using our Auto-build gang sheet builder is a game-changer. It lets you arrange several graphics on a single sheet with ease, which drastically improves cost-effectiveness by minimizing waste. If you want to dive deeper into creating the transfers themselves, you can learn more about how to make DTF transfers in our detailed guide.

The Key Advantages of Choosing DTF Printing

The buzz around DTF printing isn't just hype; it's a direct answer to the growing demand for high-quality, on-demand custom apparel. Creators and businesses are flocking to this method because it solves many of the classic headaches found in traditional printing, offering a powerful mix of versatility, quality, and durability.

This explosion in popularity is backed by the numbers. The global Direct-to-Film printing market was valued at an impressive $2.72 billion in 2024 and is projected to hit $3.92 billion by 2030. That growth is fueled by one simple fact: DTF delivers incredible prints on a massive range of fabrics, blowing past the limitations of older methods. You can dive deeper into the stats on the DTF market's impressive growth on Grand View Research.

Unmatched Fabric Versatility

One of the biggest wins for DTF printing is its ability to work with almost any fabric you can throw at it. Unlike other methods that are notoriously picky about material, DTF doesn't play by those rules.

- Cotton and Blends: It works perfectly on 100% cotton, 50/50 blends, and even tricky tri-blends.

- Synthetics: It bonds flawlessly to 100% polyester, a material that often trips up DTG printing.

- Tough Materials: It can even be pressed onto difficult surfaces like nylon, leather, denim, and canvas.

This incredible flexibility opens up a world of creative possibilities. We're talking everything from standard t-shirts and team jerseys to rugged workwear, hats, and bags—all achievable with a single print technology.

Brilliant Quality and a Soft Feel

DTF transfers are famous for producing stunning, photo-quality prints with razor-sharp details and an unlimited color palette. The secret is the white ink underbase, which ensures every color stays bright and solid, even on the darkest fabrics.

But it's not just about looks. The final print has a soft, flexible hand-feel. It stretches and moves with the fabric, so you don't get that stiff, plastic-shield feeling on your chest. It just makes the garment comfortable to wear.

A key benefit of DTF is achieving screen-print-level vibrancy and durability without the complex, costly setup. You get brilliant, full-color designs that last, whether you're printing one item or a hundred.

Durability That Lasts

A great design is worthless if it can't handle a little wear and tear. DTF prints are engineered to last, holding up through dozens of wash cycles without cracking, peeling, or fading away. The specialized adhesive creates a permanent bond with the fabric fibers, making sure your design looks fantastic for years to come.

Cost-Effective for Modern Needs

For small-to-medium-sized print runs, especially those with intricate, multi-color designs, DTF is an economic powerhouse. Traditional screen printing demands a separate screen for every single color, which racks up setup fees and makes small orders painfully expensive. DTF completely eliminates that barrier.

This is especially true when you use gang sheets. With our Auto-build gang sheet builder, you can easily pack multiple designs onto a single film. This approach maximizes every square inch of the transfer sheet, slashing your cost-per-print and making it a seriously profitable option for any custom apparel business. It's an easy-to-use tool that makes the process much more cost-effective.

How DTF Compares to Other Printing Methods

To really get what DTF printing brings to the table, it helps to put it side-by-side with the other heavyweights in the custom apparel world. Every method has its own sweet spot and is built for different kinds of jobs. Making the right call boils down to understanding the trade-offs between fabric options, the feel of the print, how long it lasts, and of course, the cost.

Let's break down how DTF stacks up against its main competitors: Direct-to-Garment (DTG), screen printing, and heat transfer vinyl (HTV). Knowing these differences will help you nail down which technique is the perfect fit for your project, making sure you get the best possible result.

DTF vs Direct To Garment (DTG)

At first glance, DTF and DTG seem like two sides of the same coin. Both are digital, both produce incredible, full-color detail. The real difference is how they get the ink onto the shirt. DTG printers work like your desktop paper printer, spraying ink directly onto the fabric where it soaks into the fibers. This gives you an unbelievably soft, breathable print with almost zero feel, but it really only plays nice with 100% cotton.

DTF flips the process around, printing onto a transfer film first, which is then heat-pressed onto the garment. This simple change makes DTF the undisputed champ of versatility. It works beautifully on cotton, polyester, nylon, and tricky blends that would make DTG inks bleed or fade. While a DTF print has a slightly more noticeable feel, it pays you back with stunning vibrancy on a much, much wider range of materials.

For a deeper dive into these two methods, check out our guide comparing DTF vs DTG printing head-to-head.

DTF vs Screen Printing

Screen printing is the OG of the t-shirt world, the long-standing industry standard for big-volume orders. The process involves pushing ink through a stenciled mesh screen onto the shirt, one color at a time. It produces incredibly durable, vibrant prints with that classic, slightly raised feel everyone knows. Its superpower is cost-effectiveness at scale—once the screens are burned, cranking out hundreds of shirts is cheap and fast.

The catch? The setup is a ton of work. Every single color in your design needs its own screen, which means high initial costs that just don't make sense for small runs or designs with a lot of colors. DTF completely changes the game here. With zero screen setup, it excels at producing full-color, photorealistic designs for small-to-medium batches at a fraction of the upfront cost.

The bottom line is this: Screen printing is your go-to for simple, high-volume orders (think 100+ shirts of the same 1-2 color design). DTF is the ideal solution for detailed, multi-color designs in any quantity.

DTF vs Heat Transfer Vinyl (HTV)

Heat Transfer Vinyl (HTV) involves cutting your design from colored vinyl sheets and pressing them onto a garment. It’s perfect for simple, bold graphics like names and numbers on team jerseys. The process is straightforward, and it opens the door to unique finishes like glitter, foil, and holographic effects that other methods can't easily replicate.

But HTV’s limits show up fast when you get into complex or multi-color designs. Each color has to be cut, weeded, and layered separately—a tedious process that’s a magnet for misalignment. DTF sidesteps all that by printing the entire full-color design in one clean pass. On top of that, DTF prints are generally softer, more flexible, and more durable than layered HTV, which can feel thick, stiff, and eventually start to crack.

When you need efficiency and fine detail, DTF is the clear winner.

Where DTF Transfers Shine in the Real World

This is where the theory ends and the practical magic begins. The true power of DTF printing isn't just in how it works, but where it works. Its versatility blows the doors wide open for businesses of all sizes, pushing creative boundaries far beyond the standard cotton t-shirt. From gritty team uniforms to crisp corporate logos on tricky fabrics, DTF is the secret sauce behind countless custom products you see every day.

This isn't just a niche trend; it's a massive market shift. The global direct-to-film printing market is projected to nearly double between 2023 and 2033, rocketing from $2.56 billion to $4.57 billion. That explosion is fueled by a huge consumer appetite for personalized gear, with the fashion and sportswear industries leading the pack. You can dive deeper into the rise of the DTF printing market on Spherical Insights.

A Game-Changer for Small Businesses and Brands

One of the best things about DTF is how it empowers the little guy. For entrepreneurs and indie fashion labels, the "print-on-demand" model is a total game-changer. Gone are the days of gambling on huge, risky inventory orders. With DTF, you can order small batches of transfers to test new designs and react to trends in real time without wasting a dime.

This "press-as-you-sell" approach keeps businesses nimble. By having pre-made transfers on hand, a small shop can press a custom design onto a blank garment the second an order hits, guaranteeing lightning-fast fulfillment with almost zero upfront cost.

For small to medium-sized businesses, DTF printing levels the playing field. It provides access to professional, full-color printing without the high setup costs or minimum order quantities required by traditional methods.

Diverse Industries and Creative Uses

The sheer flexibility of DTF means it shows up in some pretty unexpected places. Its ability to stick to just about anything makes it the go-to solution for anyone needing high-quality graphics on a variety of surfaces.

Here are just a few examples of where it excels:

- Corporate Branding: Think sharp, consistent logos on everything from staff polos and work jackets to promotional tote bags for trade shows.

- Sports Teams and Events: It’s perfect for producing those vibrant, tough-as-nails names, numbers, and mascots on polyester jerseys that have to survive game day.

- Fashion and Apparel: Designers are using it to put intricate, multi-color graphics on unique pieces like denim jackets, canvas sneakers, and snapback hats.

- Promotional Products: Because it works on non-traditional materials, it's great for customizing gear like umbrellas, coolers, or backpacks.

The real win for businesses is how cost-effective it is to combine multiple designs. Using a tool like our Auto-build gang sheet builder, you can easily cram dozens of different logos and graphics onto a single sheet. This drastically lowers the cost per print and sends your profitability through the roof.

How to Order and Apply Your DTF Transfers

Turning your digital designs into professional-grade apparel is surprisingly simple. From the moment you upload your art to the final press, getting the basics right is what separates a good print from a great one. It all starts with the quality of your artwork.

The first rule of thumb for crisp, clean DTF transfers is to start with a high-quality art file. Your design needs to be saved as a PNG with a transparent background—this is non-negotiable. It ensures the printer only lays down ink for your actual design, not a clunky background box. For results that truly pop, make sure your file has a resolution of at least 300 DPI (dots per inch).

Optimizing Your Order for Cost and Efficiency

If you want to get the absolute best value from DTF printing, you need to know about gang sheets. A gang sheet is one large transfer film packed with multiple designs. Instead of ordering individual transfers one by one, you can combine logos, sleeve hits, neck tags, and full-size graphics onto a single sheet. This simple trick dramatically drops your cost per print.

Now, arranging all those designs manually can feel like a game of Tetris you just can't win. That's where smart tools come in.

At Lion DTF, our Auto-build gang sheet builder takes care of all the heavy lifting. Just upload your designs, and the tool automatically nests them to maximize every inch of the film. It's an incredibly easy-to-use solution that saves you time, money, and a whole lot of frustration.

This level of efficiency is why so many creators, from small Etsy shops to major apparel brands, rely on DTF to get the job done. It removes the guesswork and makes sure you’re not paying for wasted space.

Your Step-by-Step Guide to a Perfect Press

Once your transfers land on your doorstep, you’re just a few moments away from a finished product. The application process is straightforward, but doing it right is crucial for a print that looks fantastic and holds up wash after wash.

Here’s a proven, step-by-step guide to applying your DTF transfers with a heat press:

- Prepare Your Garment: Start by pre-pressing your shirt for about 5-7 seconds. This little step is a game-changer—it smooths out wrinkles and removes any hidden moisture, giving you a perfect canvas.

- Position Your Transfer: Lay the DTF transfer onto the garment with the design facing down. If you're worried about it shifting, a little heat-resistant tape can help lock it into place.

- Press with Precision: Set your heat press to 240-280°F and press with firm pressure for 10 seconds. These settings can vary a bit based on the fabric, so if you’re working with a new material, it’s always smart to test a small area first.

- Peel with Confidence: This is the magic moment. For hot peel transfers, you can peel the film away immediately while it's still warm, which leaves a smooth, matte finish. If you’re using a cold peel transfer, let it cool down completely before removing the film to get a glossier look.

- Final Cure: To give your design maximum durability, cover it with parchment paper or a Teflon sheet and do a quick final press for 5-7 seconds. This locks the ink deep into the fabric fibers, creating a soft, flexible print that’s built to last.

Common Questions About DTF Printing

When you're new to DTF, a few practical questions always come up. It's one thing to see a print online, but understanding how it feels, how it holds up, and how to take care of it is what really matters. Let's tackle some of the most common curiosities so you can move forward with confidence.

So, what does a DTF print actually feel like? Forget those stiff, heavy prints from the past. A high-quality DTF transfer has a remarkably soft and flexible feel. It becomes part of the fabric, allowing it to stretch and move naturally without feeling like a plastic shield on your chest.

Durability And Care Instructions

Longevity is a huge deal for anyone creating custom apparel. How long do these transfers really last? When applied the right way, DTF prints are incredibly tough, often outlasting the garment itself. They're engineered to handle 100+ wash cycles without cracking, peeling, or fading.

To get the most life out of your prints, just follow these simple care guidelines:

- Washing: Always turn the garment inside out. Wash it in cold water on a gentle cycle.

- Drying: Tumble dry on low heat. For the absolute best results, hang it up to dry.

- Ironing: If you need to iron the garment, do it inside out on a low setting. Never, ever iron directly over the transfer.

Following these steps will keep your DTF designs looking sharp and brilliant for years.

A question we hear all the time is whether a standard home iron can be used to apply a DTF transfer. While it's technically possible, it is highly discouraged. A home iron just can't provide the consistent, even pressure and precise temperature needed for the adhesive to bond properly. This almost always leads to peeling and poor durability. A heat press is absolutely essential for professional, long-lasting results.

Ready to create stunning, durable custom apparel with total ease? At Lion DTF Transfers, we make it simple to get professional-grade prints for your projects. Use our intuitive Auto-build gang sheet builder to maximize your value and bring your designs to life with ultimate ease of use and cost-effectiveness.

Start Your Order with Lion DTF Transfers Today

Article created using Outrank