Picking the right way to print a t-shirt is a lot like choosing the right tool for a job—the best one depends entirely on what you’re trying to build. The most common methods you'll hear about are Screen Printing, Direct-to-Garment (DTG), and Direct-to-Film (DTF), and each one brings something different to the table.

Finding the Perfect T-Shirt Printing Method

Whether you're launching a brand, whipping up some merch for an event, or just making a single custom piece, knowing your options is the first step to getting a professional result. This guide will cut through the noise and help you figure out which technique actually fits your vision, budget, and how many shirts you need to make.

Each method serves a totally different purpose. Screen printing is the undisputed king of bulk orders, while DTG is perfect for those hyper-detailed, one-off prints.

Making the right choice here is a huge deal, especially if you're focused on growing your online business. It doesn’t just affect how your final apparel looks and feels; it directly impacts your profit margins and your ability to scale.

T-Shirt Printing Methods at a Glance

For anyone just looking for a quick breakdown, this table compares the most popular methods side-by-side. It hits on the big questions: cost, feel, durability, and the ideal order size for each. This should give you a solid starting point before we dive deeper.

| Printing Method | Best For | Feel on Shirt | Durability | Cost (High Volume) | Cost (Low Volume) |

|---|---|---|---|---|---|

| Screen Printing | Simple designs, large batches (100+) | Thicker, can be felt | Very High | Low | Very High |

| DTF Printing | Detailed, full-color designs; all fabric types | Smooth, flexible, slightly raised | Very High | Low | Moderate |

| DTG Printing | Photorealistic images, small batches; cotton | Soft, breathable, no feel | Moderate | Moderate | Moderate |

| Sublimation | All-over prints on polyester | No feel (dyes the fabric) | Extremely High | Moderate | High |

| Heat Transfer Vinyl | Simple text/shapes, jerseys, small runs | Varies (smooth to textured) | High | Moderate | Low |

| Embroidery | Logos, premium apparel, hats | Textured, raised stitching | Extremely High | Moderate | High |

Now that you've got the lay of the land, you can start thinking about the practical side of things, like how you'll manage your designs. With a method like DTF, for example, squeezing as many designs as possible onto one sheet is how you win on cost. This is where the right tools make all the difference.

For instance, our Auto-build gang sheet builder takes all the guesswork out of arranging multiple designs. It’s not just a user-friendly trick; it seriously boosts your cost-effectiveness by cutting down on waste, making sure you get the most value out of every single print run.

This guide will walk you through each of these techniques, breaking down what makes them tick. By the end, you'll know exactly which path to take to produce high-quality, professional-looking t-shirts that bring your ideas to life. Let’s get started.

Screen Printing: The Workhorse for Bulk Orders

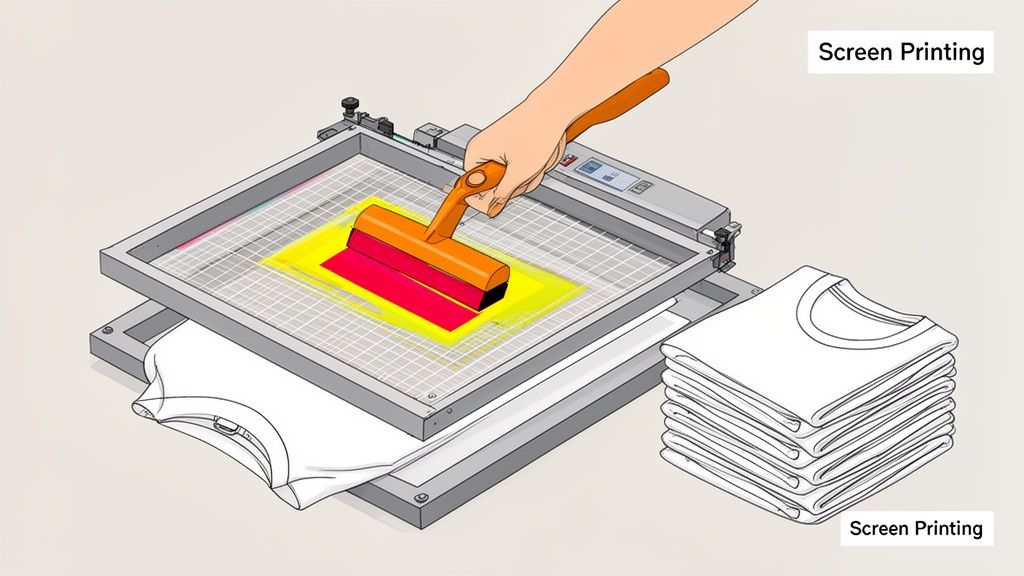

When it comes to printing t-shirts, screen printing is the undisputed champion of large-scale production. It's the OG method, and for good reason. Think of it as a highly refined stenciling process. For each color in your design, a separate mesh screen is burned with a stencil. Ink is then pushed through that screen onto the fabric with a squeegee, one color at a time.

This method has been the go-to for decades, especially for cranking out hundreds or thousands of shirts for concerts, corporate events, or merchandise lines. The logic is simple: the more you print, the cheaper each shirt becomes. While the initial setup is time-consuming and carries some cost, once those screens are made, the actual printing process is incredibly fast and efficient.

This legacy technique still holds a massive portion of the market. In fact, screen printing commands a staggering 51.8% market share in the global custom t-shirt printing industry. Its dominance comes from its unmatched cost-efficiency for big runs, which is why it remains a favorite for anyone needing to scale up their apparel. You can dig into more data on the custom apparel market in this Straits Research report.

The Tradeoffs: Durability Versus Complexity

One of screen printing’s biggest draws is the quality of the print. The inks, usually plastisol, are thick and opaque, creating vibrant, punchy colors that sit right on top of the fabric. This gives the print a slightly raised, tactile feel that just screams professional. The technique is also legendary for its durability, easily lasting 50+ washes without any serious fading or cracking. It’s the kind of print that often outlasts the shirt itself.

The main drawback, however, is the setup. Each color needs its own screen. That means a four-color design requires four separate screens, four stencil preparations, and painstaking alignment to make sure everything lines up perfectly. This complexity makes screen printing completely impractical and way too expensive for small batches or designs with lots of colors and gradients. A ten-color design for a handful of shirts? Forget about it.

This per-color setup cost is exactly why screen printing isn't built for one-off custom shirts or small, multi-design orders. The upfront investment just doesn't make sense unless you're printing in bulk.

When Screen Printing Makes Sense

So, when is screen printing the right call? It’s the clear winner in a few key scenarios:

- Large Volume Orders: If you need 100 or more identical shirts, the low per-unit cost makes it the most economical choice by a long shot.

- Simple Designs: It’s perfect for designs with one to four solid colors. Think bold logos, text-based graphics, and simple illustrations.

- Durability is Key: For uniforms, workwear, or merch that needs to survive heavy use and frequent washing, screen printing is as reliable as it gets.

For designers trying to push the boundaries with more complex visuals, there are advanced techniques. You can learn more about how creators achieve photorealistic effects with just a few colors by reading our guide on using halftones in screen printing. Ultimately, while screen printing is a powerful tool, its limitations in color complexity and small-batch affordability have paved the way for more agile digital methods to step in.

DTG Printing for Detailed One-of-a-Kind Designs

Picture a standard inkjet printer, but instead of sliding in a piece of paper, you load a t-shirt. That’s the core idea behind Direct-to-Garment (DTG) printing. This method is the star of the print-on-demand world, and for good reason—it sprays specialized water-based inks right onto the fabric, creating photorealistic images and complex color gradients with incredible precision.

Because there are no screens to set up or per-color fees, DTG is the go-to for artists selling intricate artwork or for anyone who just wants a single, highly customized shirt. There’s really no better way to capture every subtle shade in a photograph or the fine lines of a detailed illustration.

It's no surprise this digital approach is catching on. The DTG printing market is expected to grow at 12.5% annually from 2025 to 2030, making it a major player in the custom apparel game. This growth speaks volumes about its value for e-commerce sellers, hobbyists, and small-batch creators who need top-notch results on demand.

The Feel and Fabric Factor

One of the biggest selling points for DTG is how the final print feels, especially on light-colored garments. The water-based ink soaks directly into the cotton fibers, so it truly becomes part of the shirt instead of sitting on top like a plastic-y layer.

The result is an incredibly soft, breathable feel that’s almost impossible to detect by touch. It’s as if the design was woven right into the fabric, making it super comfortable to wear. But, and this is a big but, this method is pretty picky about its fabrics.

DTG works best on 100% cotton. The natural fibers are fantastic at absorbing those water-based inks. While you can sometimes get away with cotton blends, the print’s vibrancy and overall quality tend to drop off as the polyester content goes up.

Limitations and Ideal Use Cases

For all its strengths in detail and softness, DTG printing has some major drawbacks. The biggest hurdle by far is its performance on dark-colored garments. To get colors to pop on a black or navy shirt, you first have to coat the fabric with a chemical pre-treatment solution.

This solution acts as a base layer for a coat of white under-ink, but it can sometimes leave a slightly stiff or noticeable feel on the shirt. It also adds extra time and cost to every print, making it a slower and more expensive process per shirt, especially when you compare it to bulk methods.

DTG printing shines brightest for one-off prints and small, highly detailed orders. However, its dependency on cotton and the complexities of printing on dark fabrics make it less versatile than newer technologies.

This is where understanding the different types of t-shirt printing really matters. If you need a single photorealistic print on a white cotton tee, DTG is an amazing choice. But for creators who need to print on different fabrics or colors in small to medium batches, other methods strike a much better balance.

For anyone weighing their options, it’s key to understand the differences between modern digital methods. To see how they stack up directly, check out our detailed breakdown of DTF vs DTG printing, which dives deep into quality, durability, and cost. While DTG is perfect for certain jobs, its limitations are exactly why more flexible solutions have emerged.

DTF Transfers: The Modern All-in-One Solution

This is where everything comes together. Direct-to-Film (DTF) printing is the modern problem-solver, grabbing the best features from other methods and rolling them into one powerful technique. It gives you the full-color, photorealistic detail of DTG combined with the fabric versatility of screen printing.

It’s no wonder DTF is quickly becoming the go-to for small businesses and growing apparel brands.

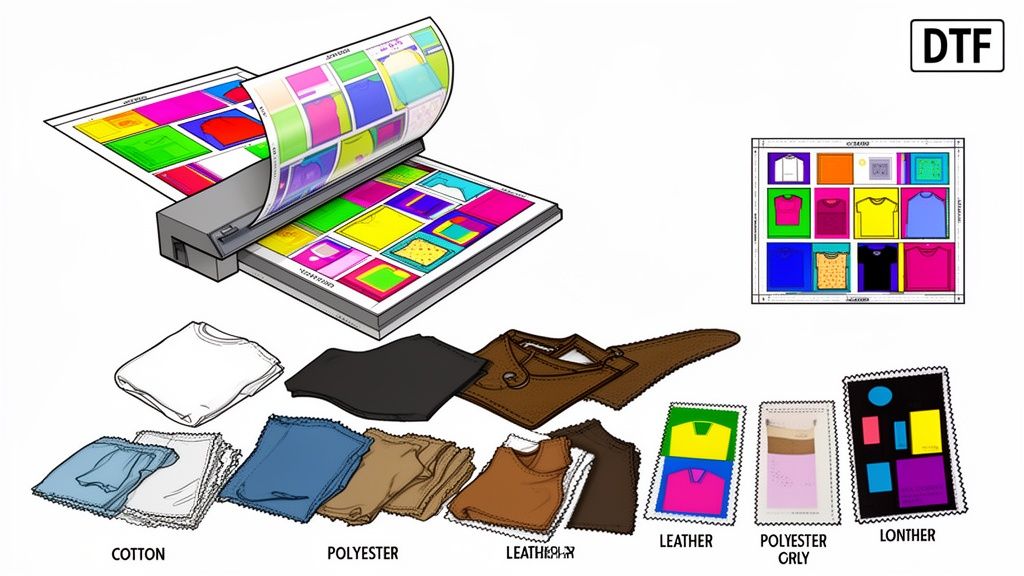

The process is surprisingly straightforward. A special printer lays down water-based inks onto a clear film. Then, a powdered adhesive gets applied to the wet ink, is melted to create a stable transfer, and that's it. Your design is ready to be applied to almost anything with a simple heat press.

This method unlocks professional-grade results without the crazy learning curve or massive equipment costs tied to other techniques.

Unmatched Versatility Across Fabrics and Colors

Here's the real game-changer: DTF's universal compatibility. While DTG struggles with polyester and screen printing needs different ink formulations for different materials, DTF just works. It bonds perfectly to cotton, polyester, blends, nylon, leather—you name it.

This flexibility is huge for brands wanting a consistent look across a wide range of products, from t-shirts and hoodies to hats and bags. Plus, it excels on any color garment, light or dark, without the chemical pre-treatment that can leave a stiff feel on DTG prints. Your colors stay bright and opaque, every time.

DTF effectively breaks down the fabric barriers that hold creators back. It's a single, reliable solution for producing high-quality, full-color designs on just about any apparel item, seriously streamlining the entire production process.

If you're just starting, this means you can test out all sorts of different products without having to become an expert in multiple printing methods.

Durability and Quality That Lasts

When you talk about longevity, DTF transfers are in a league of their own. The combination of flexible inks and a powerful adhesive creates a print that stretches with the fabric. That means it resists the cracking and peeling that often ruins lower-quality heat transfers.

Properly applied DTF prints have been tested to withstand over 100 washes without any significant fading. This level of durability is right up there with screen printing, and often even better, making it perfect for workwear, athletic apparel, or any garment that needs to stand up to real life.

- Vibrant and Sharp: DTF nails fine lines and complex color gradients with photographic clarity.

- Soft Hand Feel: While it's a transfer that sits on the fabric, the final print is thin, flexible, and feels much softer than old-school vinyl.

- Excellent Stretch and Rebound: The design moves with the garment and snaps back into shape without damage.

The Sweet Spot for Modern Creators

DTF hits the perfect balance of cost, quality, and efficiency, especially for small businesses and growing brands. You get professional results that can go head-to-head with major retail brands, but you don't need the high minimum order quantities that screen printing demands. It's ideal for launching new designs, doing limited-edition drops, or handling print-on-demand orders.

To make it even more economical, you have to use an Auto-build gang sheet builder. This tool lets you cram multiple designs onto a single large film sheet, which drastically cuts your cost per print. You pay for the sheet, not for each individual design, so you can maximize every square inch of film and slash your waste.

This approach makes DTF an incredibly budget-friendly choice for small to medium-sized runs. If you want to dive deeper, you can find out more about getting started with custom DTF transfers in our complete guide. It’s the key to making pro-level apparel printing accessible for everyone.

Taking a Look at Other T-Shirt Customization Methods

While screen printing, DTG, and DTF are the big three that handle most modern apparel jobs, a few other specialized techniques are worth knowing. They each bring something unique to the table for specific projects.

Think of these as the specialists in your printing toolbox. They might not be your everyday workhorses, but when the right job comes along, they’re the only way to get a particular look, feel, or function.

Heat Transfer Vinyl for Bold and Simple Graphics

Heat Transfer Vinyl (HTV) is a huge favorite for crafters, Etsy sellers, and anyone needing simple, durable graphics in small numbers. The process is pretty hands-on: a design is cut from a sheet of colored vinyl with a cutting machine, then you use a heat press to melt and bond the vinyl onto the shirt.

It’s the perfect method for putting names and numbers on sports jerseys or creating bold, single-color logos for a small team or event. Since every color is a separate piece of vinyl, it’s a non-starter for complex, multi-color images, but it absolutely nails crisp lines and solid shapes.

- Best For: Simple text, logos, and personalizing items with names or numbers.

- Feel: Creates a distinct layer on top of the fabric. It can range from smooth and thin to thick and textured, depending on the vinyl.

- Durability: High-quality HTV is incredibly durable and can outlast the shirt itself without peeling or cracking.

The DIY nature of HTV makes it super accessible, but it gets tedious fast. For larger orders, having to cut, "weed" (remove the excess vinyl), and press each piece one-by-one just doesn't scale.

Sublimation for Permanent All-Over Prints

Sublimation is a wild process that feels a bit like magic. It uses special inks that, when heated, turn directly into a gas and permanently dye the actual fibers of the fabric. The design becomes part of the shirt, not just a layer sitting on top.

This leaves you with an incredibly soft, breathable print that has zero feel to it. Because the ink is in the fibers, the design will never crack, peel, or fade, making it one of the most durable options out there. It’s the go-to method for those vibrant, edge-to-edge, all-over prints you see on athletic wear.

But here’s the catch: Sublimation is picky about fabric. The process only works on 100% polyester or high-polyester blends and is only visible on light-colored garments. The inks are transparent, so they just won’t show up on a dark background.

Beyond the print itself, thinking about the customer's experience is key. For custom shirts, especially with complex all-over designs, tools like a virtual try on can be a game-changer, letting buyers see exactly how a design will look on them before they commit.

Embroidery for a Premium Textured Finish

Lastly, there's embroidery. It isn't a printing method at all—it's stitching. A design is digitized into a format a machine can read, which then uses thread to stitch it right onto the fabric. This creates a textured, three-dimensional design that just screams quality and professionalism.

Embroidery is the undisputed champ for corporate logos on polo shirts, monograms on jackets, or emblems on hats. It gives you a premium, classic look that no ink-based method can touch. The durability is second to none; an embroidered design will almost always outlast the garment it's stitched on.

Of course, its strengths are also its weaknesses. Embroidery is not built for photorealistic images or designs with subtle color gradients. It really shines with simple, bold graphics and logos. The cost is also typically higher than printing, which makes sense given the time and materials involved.

Each of these methods fills a specific niche in the apparel world. While DTF strikes the best all-around balance of quality, versatility, and cost for most projects—especially when you use an Auto-build gang sheet builder for max efficiency—understanding HTV, sublimation, and embroidery means you can pick the absolute best tool for any job you can dream up.

How to Choose the Right T-Shirt Printing Method

Alright, now that you’ve got a handle on the different printing methods, let's put that knowledge to work. Picking the right one isn’t about finding a single “best” option—it’s about finding the best fit for your specific project.

To make the right call, you really need to look at your project from five different angles: how many shirts you need, what they're made of, how complex your design is, your budget, and how long you need the print to last. Each of these factors will point you toward a different solution, helping you narrow down the field and sidestep any costly mistakes.

Answering the Five Core Project Questions

Start by asking yourself these critical questions. Your answers will quickly tell you which printing methods are even on the table for your job.

- How many shirts do you need? For bigger orders of 50+ identical items, you just can’t beat the cost-per-shirt of screen printing. But if you're doing a small batch, a one-off sample, or a run with lots of different designs, digital methods like DTF and DTG are way more economical.

- What fabric are you printing on? This is a huge one. DTG really shines on 100% cotton, but sublimation is strictly for light-colored polyesters. DTF transfers, on the other hand, are the most flexible of the bunch, working brilliantly on cotton, polyester, blends, and even tricky materials like nylon or leather.

- How complex is your design? Got a simple text-based logo with just a few colors? Screen printing and HTV are fantastic choices. But for photorealistic images, gradients, and designs with unlimited colors, DTG and DTF are the clear winners.

- What's your budget per shirt? High setup costs make screen printing expensive for small runs, but that cost drops dramatically as your quantity goes up. DTF offers a great middle ground, giving you professional quality without needing to order hundreds of pieces.

- How durable does the print need to be? For maximum longevity, sublimation, screen printing, and high-quality DTF transfers are top-tier. In fact, a good DTF print is often tested to withstand 100+ washes, making it perfect for workwear, team jerseys, or anything that's going to see heavy use.

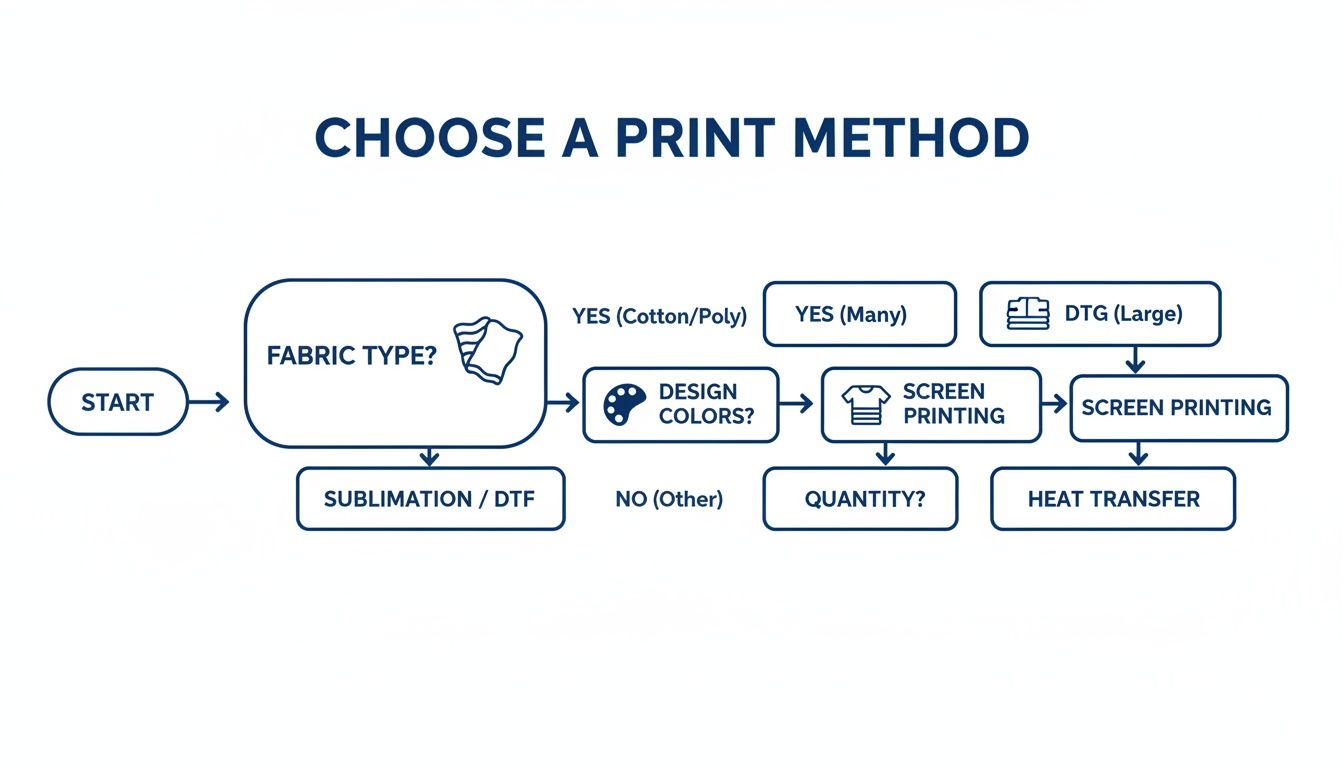

This decision tree gives you a great visual for how to walk through these questions—fabric, design complexity, and quantity are the big three that guide your choice.

As the chart shows, your project's specific needs—like needing to print full-color designs on dark polyester—will quickly rule out some methods while making others the obvious choice.

Decision Matrix: Which Printing Method Is Best for You?

To make this even clearer, let's lay out the main contenders side-by-side. Use this table to compare the top printing methods based on the specific requirements of your project, helping you make the most informed and cost-effective choice.

| Factor | Screen Printing | DTG | DTF Transfers | HTV |

|---|---|---|---|---|

| Best Quantity | 50+ | 1-25 | 1-500+ | 1-10 |

| Design Complexity | Simple (1-5 colors) | Photorealistic, unlimited colors | Photorealistic, unlimited colors | Simple text & shapes |

| Durability | Excellent (50-100+ washes) | Good (25-50 washes) | Excellent (100+ washes) | Good (25-50 washes) |

| Fabric Versatility | Good (Cotton, Blends) | Poor (Best on 100% Cotton) | Excellent (Any Fabric) | Good (Cotton, Poly, Blends) |

| Feel on Shirt | Thicker layer of ink | Soft, breathable feel | Smooth, flexible layer | Stiff, vinyl-like layer |

This matrix really highlights the trade-offs. While screen printing is a workhorse for big jobs and DTG is great for cotton one-offs, DTF consistently hits that sweet spot of versatility, durability, and quality across the board.

Why DTF Is Often the Modern Sweet Spot

For most creators, small businesses, and growing brands, DTF transfers consistently emerge as the most balanced solution. It simply excels where other methods force you to compromise, offering vibrant quality, incredible fabric versatility, and top-tier durability.

The real advantage of DTF is its ability to deliver professional, retail-quality results on small-to-medium batches without breaking the bank. It removes the barriers of fabric limitations and high setup costs, making it a powerful and accessible option.

The cost-effectiveness of DTF gets even better when you optimize your prints. Using a tool like our Auto-build gang sheet builder is a perfect example. It lets you pack multiple designs onto a single film sheet, which dramatically lowers your cost per print and slashes waste. This one step makes an already efficient process even more profitable, giving you the freedom to test new designs and expand your product line with total confidence.

T-Shirt Printing Questions We Hear All the Time

As you dive into the world of custom apparel, a few questions always pop up. We've tackled the most common ones here to give you the clarity you need to move forward with your project.

What Is the Most Durable T-Shirt Printing Method?

When it comes to durability, it's really a two-way tie between screen printing and top-tier DTF transfers. A well-made screen print can easily handle 50+ washes, which is why it's been a classic for so long.

But this is where things get interesting. Premium DTF transfers have been tested to withstand over 100 washes, making them a true powerhouse for longevity. For designs with fine lines or intricate details that need to hold up against serious wear and tear, DTF is often the better bet.

Can I Print a Photograph on a T-Shirt?

You absolutely can. For photorealistic images packed with colors and subtle gradients, your best options are Direct-to-Garment (DTG) and Direct-to-Film (DTF). Both are fantastic at recreating complex digital art without the tedious color separation that screen printing requires.

DTF often pulls ahead with more vibrant results, especially on dark fabrics. It ensures your photo looks sharp, punchy, and true to the original file.

The ability of DTF to handle intricate, full-color designs on virtually any fabric is what makes it such a versatile and powerful choice for modern creators who need both quality and flexibility.

How Can I Make Small-Batch Printing Cost-Effective?

This is where DTF really shines. For smaller runs, DTF transfers are hands-down the most cost-effective way to get professional-grade results. You don't have to worry about the high setup fees per color or design that come with screen printing.

To really get the most bang for your buck, you'll want to use a service that offers an Auto-build gang sheet builder. This tool lets you fit multiple different designs onto a single transfer sheet. It dramatically drops your cost per print and cuts down on wasted material, making even the smallest orders profitable.

Ready to create vibrant, durable, and cost-effective prints for any project? The Lion DTF Auto-build gang sheet builder makes it easy to maximize every order. Build your custom gang sheet today!