A UV DTF gang sheet is a pretty straightforward concept: it’s one large transfer film loaded up with multiple designs, all ready for application on hard, non-porous surfaces. It's an incredibly cost-effective and efficient way to create vibrant, adhesive-backed decals. Best of all? You don't need a heat press, which makes it perfect for customizing items like glass, metal, and wood.

Understanding the Power of a UV DTF Gang Sheet

Ever bake cookies? You wouldn't bake them one by one. Instead, you'd fill a single baking sheet with different shapes to make the most of your oven space. A UV DTF gang sheet follows that exact same logic for custom printing.

This method lets you arrange and print a bunch of unique designs—logos, detailed graphics, tiny text—all onto one big adhesive sheet. Consolidating your designs like this is a smart move that seriously cuts down on material waste and brings your production costs way down. For ultimate ease of use and cost-effectiveness, using an Auto-build gang sheet builder can automatically arrange your designs to maximize space.

But these aren't your typical fabric transfers. UV DTF decals are specifically engineered for hard, non-porous surfaces, opening up a whole new world of customization for items that could never survive a heat press. Think about personalizing anything from glass mugs and metal tumblers to plastic phone cases and finished wood plaques.

The Magic Behind the Acronym

Let's quickly break down the name. "UV" stands for ultraviolet light, which is used to instantly cure the ink and make it incredibly durable. "DTF" means Direct-to-Film, describing how the design is printed directly onto a specialized film.

What you get is a vibrant, permanent decal that looks and feels almost like it was painted right onto the surface, with no weird background or clear outline around the design.

The core benefits of this technology are pretty clear:

- No Heat Required: Application is a simple peel-and-stick process. All you need is a little pressure, making it completely safe for heat-sensitive items.

- Versatile Application: It sticks perfectly to a massive range of hard surfaces, including glass, metal, plastic, ceramic, and treated wood.

- Exceptional Durability: The UV-cured ink is waterproof, scratch-resistant, and tough enough to handle harsh conditions without fading.

- Cost-Effective Production: Printing multiple designs on a single sheet is the best way to minimize waste and lower your cost per individual design. Using our Auto-build gang sheet builder makes this even more cost-effective.

UV DTF vs Traditional DTF At a Glance

It's easy to get UV DTF and standard DTF mixed up, but they serve completely different purposes. This table breaks down the key differences to help you choose the right transfer for your project.

| Feature | UV DTF Transfers | Standard DTF Transfers |

|---|---|---|

| Primary Use | Hard, non-porous surfaces (glass, metal, plastic, wood) | Fabrics (cotton, polyester, blends) |

| Application Method | Peel-and-stick (pressure-sensitive adhesive) | Heat press required |

| Required Equipment | None (just your hands!) | Heat press |

| Durability | Waterproof, scratch-resistant, and permanent | Washable, stretchable, and durable on garments |

| Ideal For | Mugs, tumblers, phone cases, laptops, signs, promotional hard goods | T-shirts, hoodies, hats, tote bags, and other apparel |

In short, if you're decorating a t-shirt, you need standard DTF. If you're customizing a tumbler or a laptop, UV DTF is your go-to.

Simplifying the Process for Everyone

While the tech behind it is pretty advanced, getting started is easier than you might think. For instance, our Auto-build gang sheet builder was designed to be as user-friendly and cost-effective as possible. The tool automatically arranges your uploaded designs to squeeze as many as it can onto the sheet, which completely removes the guesswork and tedious manual layout work.

This kind of efficiency makes powerful printing accessible to everyone, from small businesses creating promotional merch to crafters personalizing one-of-a-kind gifts. The market for this is blowing up; in fact, the global UV DTF sector, valued at US$215 million, is projected to more than double to US$442 million by 2033. This growth is all about the rising demand for durable, high-quality customization across tons of industries.

For a deeper dive into the specifics, check out our guide on UV DTF transfers. You can also discover more about the booming market and its future from various industry reports.

How UV DTF Printing Actually Works

To really get why a UV DTF transfer looks so good, it helps to understand the multi-layered process behind it. This isn't just simple printing. Think of it more like building a high-tech, adhesive sandwich where every single layer has a job to do. This unique method is what allows the final design to stick to hard surfaces without needing any heat at all.

The whole thing starts with a clear base, not color. The very first layer that goes down on the special "A" film is a strong adhesive. This is the foundation that will eventually lock your design onto the target object, giving the transfer its powerful grip on tricky surfaces like glass, metal, or plastic.

Building the Layers of Ink

Right on top of that adhesive, the printer lays down a crucial layer of white ink. This opaque base acts as a primer, making sure the colors printed on top of it are bright and vibrant, no matter what color the surface is underneath. Without it, your design would look dull and washed out on a dark mug or tinted glass.

After the white base is set, the printer gets to work on the CMYK (Cyan, Magenta, Yellow, and Black) inks. This is where your design bursts to life with rich, accurate colors. As each drop of ink is applied, powerful UV lights instantly cure—or harden—it. This immediate curing process is what gives "UV DTF" its name. It also prevents the ink from smudging or bleeding, which is how you get those exceptionally sharp details.

The final touch is a layer of protective varnish. This clear top coat is like the clear coat on a car's paint job. It seals the design and gives it a tough, glossy finish that resists scratches, water, and fading.

The A and B Film System

The entire process relies on two separate films that work together as a team:

- The 'A' Film: This is the main sheet where all the layers are printed in order: adhesive, white ink, color ink, and finally, varnish.

- The 'B' Film: After printing, the 'A' film is laminated with this second film. The 'B' film is basically the carrier sheet that holds everything together until you're ready to apply the transfer.

This two-film system creates a stable, ready-to-use decal. When it's time to apply it, you just peel the design off the original backing paper, stick it on, and the 'B' film is the last thing you peel away. All that's left behind is the perfectly cured ink and adhesive. This process is totally different from other methods, and you can learn more about how it stacks up by exploring what standard DTF printing is and its focus on fabrics.

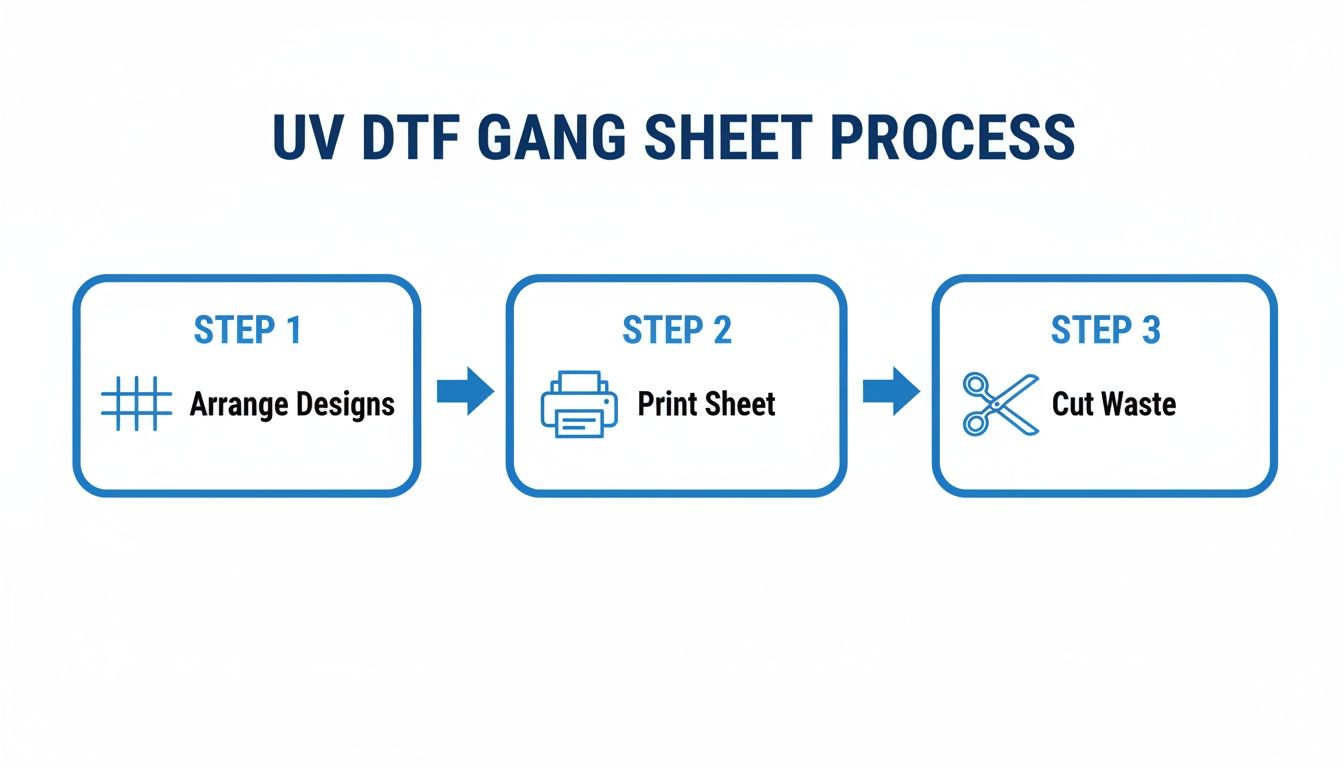

The visual below gives you a simplified look at the workflow for getting a UV DTF gang sheet ready to go.

This workflow shows just how important it is to arrange your designs to maximize every inch of space, which is the key to creating a cost-effective UV DTF gang sheet. While you could do this manually, our Auto-build gang sheet builder automates the whole thing, making sure you fit as many designs as possible onto your sheet for ultimate savings and ease. The result is a perfectly optimized sheet, printed with precision and ready for you to cut and apply.

Creating the Perfect Print-Ready Gang Sheet

Your final UV DTF transfer is only as good as the design file you start with. Seriously. Preparing a print-ready gang sheet is the single most important step you can take to make sure your decals come out sharp, vibrant, and exactly how you pictured them.

Think of it as the blueprint for your final product. Any mistake or shortcut in the plan will show up in the finished transfer, and nobody wants that. The goal is to create a file that communicates perfectly with our printers, leaving zero room for error. It sounds technical, but it really boils down to getting a few key details right from the start.

Foundational File Requirements

Before you even think about arranging your designs, you have to nail two non-negotiable file settings. These fundamentals are what separate a crisp, professional print from a blurry, amateurish one.

First is resolution. Your file must be 300 DPI (Dots Per Inch). This is the gold standard for high-quality printing, period. Anything less will look pixelated and fuzzy. Going higher won't make a noticeable difference in quality but will create a massive, clunky file.

Second is a transparent background. You absolutely have to save your designs as a PNG file with transparency enabled. This ensures only your artwork gets printed—no ugly white or colored boxes around it. It’s what gives you that clean, "painted-on" look that makes UV DTF so impressive.

Pro Tip: Try to avoid super fine or delicate lines in your artwork. While UV DTF is incredibly precise, details that are only a few pixels thin might not transfer well. There simply isn't enough surface area for the adhesive and ink to grab onto reliably.

Sizing and Arranging Your Designs

Once your individual files are prepped, it's time to arrange them on the gang sheet canvas. The main goal here is efficiency—fitting as many designs as you can onto a single sheet to get the most bang for your buck. You can absolutely do this by hand, carefully rotating and nesting your graphics to fill in every last bit of space.

But let's be honest, that manual process can be a real headache. It’s easy to accidentally overlap designs or leave too much empty space, which is like throwing money away. This is where automated tools become a lifesaver for creators at every level.

Tools like our Auto-build gang sheet builder take all the guesswork out of it. You just upload your individual PNG files, and the software intelligently analyzes their shapes and sizes. It then automatically rotates and nests them into the most efficient layout possible, maximizing your print area for ultimate cost-effectiveness and ease of use. It saves a ton of time and prevents those common, costly mistakes.

The efficiency of using a uv dtf gang sheet is a total game-changer for so many businesses. Gang sheets are transforming print-on-demand, letting producers consolidate dozens of orders onto one sheet, which dramatically slashes waste and production costs. The broader DTF printer market, where UV tech is a major player, is on track to hit USD 4.25 billion by 2032. It's not uncommon for businesses to see a 50% boost in their output just by switching to UV DTF gang sheets, helping small shops handle hundreds of transfers a day. For more on these industry trends, you can find market reports from sources like 360iResearch.com.

For those who prefer a more hands-on approach with their favorite design software, that's totally fine too. In fact, you can check out our guide on how to create a DTF gang sheet in Canva, which walks you through the entire manual setup, step-by-step.

Applying Your UV DTF Transfers for Flawless Results

This is where the magic really happens. You’ve designed your layout, received your custom UV DTF gang sheet, and now it’s time to turn those designs into durable, stunning decals. The best part? There’s no heat press or complicated equipment needed—just a few simple steps stand between you and a professional-grade finish.

The whole process is essentially a peel-and-stick application, but getting it right is what creates that flawless, "painted-on" look. Precision is everything here, as it ensures a strong, bubble-free bond that’s built to last. Let's walk through the exact steps to apply your transfers like a seasoned pro.

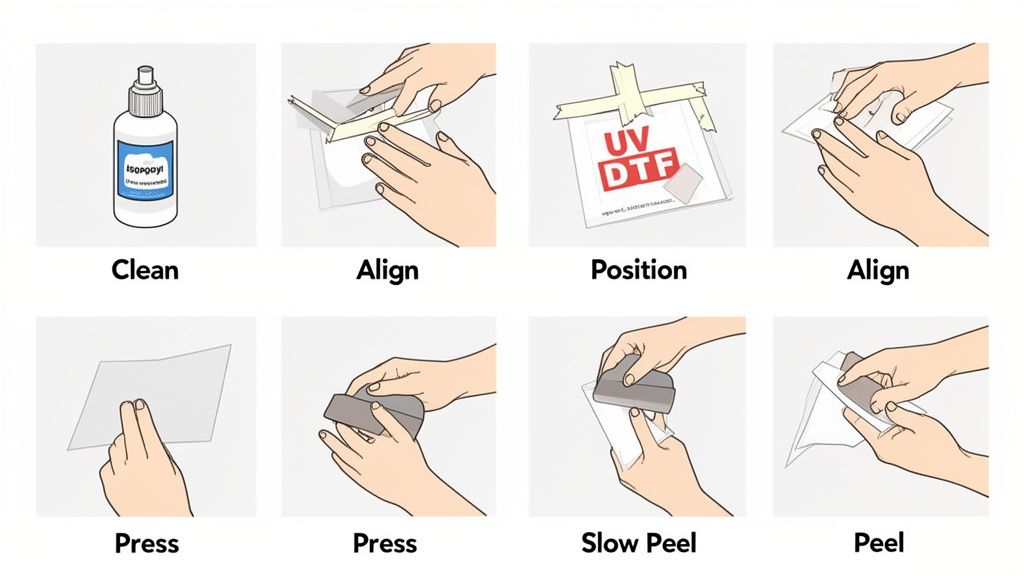

The Four Steps to a Perfect Application

Stick to this simple, four-part process, and you’ll get incredible results every single time. It’s a method that works on just about anything, from tumblers and mugs to phone cases and laptops.

-

Clean the Surface: This is easily the most critical step. Start with a completely pristine surface by wiping the area with isopropyl alcohol and a lint-free cloth. This gets rid of any dust, oils, or stray residues that could get in the way of the adhesive, guaranteeing the strongest bond possible.

-

Position Your Decal: Carefully peel the transfer off its white paper backing. Try not to touch the sticky side with your fingers—oils from your skin can weaken the grip. Once it's free, align the transfer exactly where you want it on the object.

-

Apply Firm Pressure: With the transfer in position, press it down firmly. Use a squeegee to apply even, overlapping strokes, working from the center outward. This is how you push out any trapped air bubbles and make sure every bit of the design makes solid contact with the surface.

-

Peel the Carrier Film: Time for the final reveal. Slowly and carefully peel back the clear carrier film, starting from one corner. Keep the film low to the surface and pull it back at a sharp angle. If you see any part of the design lifting, just lay the film back down, squeegee over that spot again, and then continue peeling.

Insider Tricks for Tricky Applications

While the standard method is perfect for flat surfaces, curved or complex shapes require a little more finesse. For items like tumblers, helmets, or anything with a contour, the "hinge method" is your new best friend.

Here’s how it works: place your transfer (with the backing still on) right where you want it. Then, apply a piece of masking tape across the top or middle to create a "hinge" that holds it in place. You can now lift the transfer, peel off the backing from the un-taped side, and smooth it down section by section. This technique prevents misalignment and makes it way easier to handle bigger decals on rounded objects.

Key Takeaway: Patience is your most important tool during application. Rushing the process, especially when peeling the carrier film too quickly, is the number one cause of bubbles, tears, or poor adhesion. Take your time for a perfect result.

Common Mistakes to Avoid

A professional finish is just as much about knowing what not to do. Steer clear of these common slip-ups, and you'll set yourself up for success on your very first try.

- Applying to a Dirty Surface: If you skip the alcohol wipe, you risk the transfer peeling off way too soon.

- Touching the Adhesive: The oils from your hands will definitely compromise the bond.

- Peeling the Film Too Fast: This can cause parts of your design to lift right off or even tear.

- Not Using Enough Pressure: A weak press won't get rid of air bubbles or fully activate the adhesive.

By following these guidelines, your finished product will look sharp and professional. Beyond everyday items, the precise application of UV DTF also makes it great for specialized signage, like when printing on materials like Coroplast for durable, vivid displays. The principles of a clean surface and firm pressure are universal.

Unlock New Business Opportunities with UV DTF

Ready to move beyond just apparel? A UV DTF gang sheet is your ticket to a massive world of customizing hard goods. This is where you can turn everyday items into personalized, high-margin products and open up entirely new revenue streams for your business.

Think about it: by grouping multiple designs onto one sheet, you can produce decals for an entire product line in a single run. It's the perfect method for creating branded promo items, personalized gifts, and all the unique custom gear that customers are looking for.

From T-Shirts to Tumblers and Beyond

Imagine taking your business, which might have started with t-shirts, and suddenly launching a full line of durable, high-end merchandise. That’s the power UV DTF transfers put in your hands. The ability to decorate non-fabric items without a heat press is a serious game-changer.

You can start creating profitable products that command higher prices and attract a completely different customer base. The possibilities are huge:

- Branded Promotional Items: Offer businesses custom pens, keychains, phone cases, and USB drives with their logos. These are often high-volume orders that can become a steady source of income.

- Personalized Drinkware: Create stunning, durable designs for coffee mugs, tumblers, and water bottles. The market for these items—think weddings, corporate gifts, and personal accessories—is massive.

- Unique Custom Gear: Decorate toolboxes, helmets, fishing lures, and other specialty equipment. These niche markets have passionate customers who are more than willing to pay a premium for customization.

The Power of a Premium Finish

One of the standout features of a UV DTF transfer is its premium, slightly raised finish. It looks and feels like a high-end application, which instantly elevates the perceived value of any product it’s on. This isn't just some flimsy sticker; it's a permanent, professional-grade decal.

This quality lets you position your products in a more premium category. For example, a plain $10 tumbler can easily become a $25 personalized piece of drinkware with a well-designed UV DTF transfer. That significant margin increase is exactly how you can scale your business and boost your bottom line, fast.

The direct-to-film printing market is projected to hit USD 3.92 billion by 2030, and the versatility of UV DTF is a major reason why. Data shows that UV DTF transfers can last 50% longer than standard DTF, with 98% color retention after 100 cycles, making them ideal for durable items like mugs and outdoor banners.

Making It Easy and Cost-Effective

Jumping into a new market can seem intimidating, but it doesn’t have to be. Creating your own UV DTF gang sheet makes the whole process incredibly cost-effective. By filling a sheet with multiple designs for different products, you minimize waste and bring your cost per decal down to just pennies.

Business Growth Insight: By diversifying your product line with UV DTF, you're not just selling more items—you're capturing a larger share of your customer's wallet and building stronger brand loyalty. A customer who buys a custom t-shirt might also need a matching custom mug or phone case.

Of course, as you plan to commercialize your UV DTF skills, it's smart to tackle the business setup process early on, including understanding legal requirements like needing an LLC to sell on Shopify. A solid foundation is key to long-term success.

To make this transition even smoother, our Auto-build gang sheet builder takes all the guesswork out of ordering. Just upload your designs, and the tool automatically arranges them for maximum efficiency, ensuring you get the absolute best value from every sheet. This simplicity makes it easy for any business to start offering a wide range of customized hard goods.

Why Lion DTF Is Your Go-To Printing Partner

Choosing the right supplier for your UV DTF gang sheet is a huge deal. It’s not just about getting a decent print; it’s about the quality, the speed, and the support you get when you need it. Thousands of creators and businesses trust Lion DTF because we’re obsessed with making professional-grade printing easy and accessible for everyone.

We started by tackling the biggest time-waster: layout. We know that manually arranging dozens of designs is tedious and kills your efficiency. That's why we built our own Auto-build gang sheet builder, a tool designed to simplify ordering and get you the most for your money. Just upload your designs, and it automatically nests them into the most cost-effective layout. No wasted space, maximum value.

More Than Just a Printer

Beyond the smart tools, our main focus is on delivering knockout quality and speed. We make sure every single transfer has vibrant, accurate colors and durability that actually holds up in the real world. We back that promise with some of the fastest turnaround times in the business.

- Rapid Shipping: Most orders are out the door in just 1-2 business days.

- Next-Day Air Options: Got an urgent project? We offer expedited shipping to get it there fast.

- Same-Day Pickup: Local customers can grab their orders even quicker.

We believe technology should serve people, not replace them. That’s why our customer support is run by real, knowledgeable humans who are ready to help you succeed.

But what really makes us different is our commitment to real, human support. When you have a question or need a hand, you won’t get stuck talking to a bot. Our team is here to help by phone, text, or email. Whether you need us to build a gang sheet for you or just want some advice on your project, we’ve got your back.

We're not just a printer; we're a partner invested in helping you grow. The proof is in the thousands of 5-star reviews from customers who count on us for consistent quality and service they can depend on. When you choose Lion DTF, you’re choosing a team that’s genuinely excited to help bring your vision to life.

Got Questions About UV DTF? We've Got Answers.

Jumping into the world of UV DTF can bring up a few questions, especially when you're just getting your feet wet. We've pulled together some of the most common things our customers ask to give you clear, straight-up answers.

Think of this as your quick guide to getting the small details right. Nailing these points will help you skip the common mistakes and create some seriously impressive, long-lasting products.

Are UV DTF Transfers Dishwasher Safe?

While our UV DTF transfers are incredibly tough and 100% waterproof, we always recommend hand washing to get the longest possible life out of them, especially on drink-ware. We do not ever recommend using a dishwasher. The combo of high heat and harsh detergents in most dishwashers can slowly break down the adhesive over many cycles. Also, for safety, they are not considered microwave safe.

What Surfaces Are a No-Go for UV DTF?

UV DTF transfers are made specifically for hard, smooth, non-porous surfaces. They are not designed for fabrics like cotton or polyester—that's a job for our standard DTF transfers.

You might also have a tough time getting them to stick properly to:

- Anything oily or waxy

- Rough or highly textured materials, like some raw, unfinished wood

- Certain types of rubberized or silicone plastics

When in doubt, always test a transfer on a small, hidden spot first before you commit to the full application.

How Is This Different From a Vinyl Sticker Sheet?

The biggest differences come down to the application process and the final look. A UV DTF transfer leaves only the ink and adhesive behind, giving you a seamless, "painted-on" finish with zero background or clear border. The best part? This process requires absolutely no weeding, which is a huge time-saver.

A vinyl sticker, on the other hand, is a single piece that includes its background material, whether it's clear or a solid color. UV DTF is also typically more resistant to scratches, chemicals, and water than most printed vinyl.

Do I Need a Heat Press to Apply UV DTF Transfers?

Nope, not at all. A heat press is not needed and should never ever be used with UV DTF transfers. The high temperatures will melt and ruin both the transfer and its special adhesive. Application is all about firm, even pressure, making it perfect for items that can't handle the heat.

As you plan your projects, remember that designing an efficient uv dtf gang sheet is the smartest way to produce a bunch of different designs at once. Our Auto-build gang sheet builder takes all the guesswork out of the layout, making sure you get the most value and cost-effectiveness every single time.

Ready to take your hard-good customizations to the next level? At Lion DTF Transfers, we make it simple to get professional-grade prints with a fast, reliable service you can count on.