When you're trying to decide between buying the best DTF printer for your small business and just outsourcing the prints, it really boils down to one thing: control versus convenience.

Owning the machine gives you total control, but it comes with a hefty upfront investment and the added job of running and maintaining it. On the other hand, outsourcing gives you incredible flexibility and predictable costs with zero maintenance headaches. The right choice depends entirely on whether you need on-demand production capacity right now or if you're playing the long game for operational efficiency.

The Core Decision: Buy a DTF Printer or Outsource?

For any small business in the custom apparel game, you eventually hit a fork in the road. Do you invest in your own equipment or partner up with a specialized transfer provider like us? This isn't just about buying a new piece of gear; it's a strategic move that will shape your finances, your time, and how fast you can grow.

Before you even think about purchasing a printer, it's a good idea to realistically look at the different sources of capital available. A good DTF setup isn't cheap, and you need to be prepared for the total cost of ownership.

This flowchart breaks the decision down into the three biggest factors: your production volume, your budget, and the space you have available.

As you can see, if you're already pushing high, consistent order volumes and have the cash and dedicated space, buying your own printer makes a lot of sense. But for everyone else—especially those with fluctuating demand, a tight budget, or a cramped workspace—outsourcing is almost always the smarter move.

Understanding the Trade-Offs

Let's be clear: when you choose to buy a DTF printer, you're also signing up for a second job as a printer operator and maintenance tech. The sticker price is just the entry fee. You also have to factor in the ongoing costs of consumables, the potential for downtime when something breaks, and the steep learning curve it takes to get consistently great prints.

The global Direct-to-Film (DTF) printing market, which powers solutions like ours, was valued at USD 2.72 billion in 2024 and is projected to surge to USD 3.92 billion by 2030. This growth is a testament to how effective and popular this technology has become.

Outsourcing to a provider like Lion DTF Transfers flips the script. It turns a massive capital expense into a simple, predictable operational cost. You get instant access to our industrial-grade equipment and our team's expertise without any of the maintenance headaches. This frees you up to focus on what actually grows your business: designing, marketing, and taking care of your customers.

To make this even more efficient, our Auto-build gang sheet builder helps you maximize every square inch of film, driving your cost-per-print down and your profits up. It's a simple, easy-to-use tool that directly improves your cost-effectiveness.

Quick Decision Matrix: Owning vs. Outsourcing DTF

To help you see the differences at a glance, we've put together this quick comparison table. Think of it as a cheat sheet for figuring out which path aligns best with your current business needs.

| Business Factor | Best for Owning a DTF Printer | Best for Outsourcing to a Provider |

|---|---|---|

| Order Volume | High and consistent (500+ prints/month) | Fluctuating or low-to-medium volume |

| Upfront Budget | Sufficient capital for printer, supplies, and ventilation ($5,000+) | Limited capital; prefer a pay-as-you-go model |

| Technical Skill | Comfortable with daily maintenance and troubleshooting | Prefer to focus on design and sales, not machine upkeep |

| Workspace | Dedicated, well-ventilated room (100+ sq. ft.) | No extra space required; a home office is sufficient |

| Speed to Market | Slower initial start due to setup and learning curve | Immediate; can start selling the same day |

Ultimately, the table highlights a clear pattern. Owning a printer is a powerful move for established, high-volume businesses ready to take on the operational responsibilities. For everyone else, outsourcing offers a faster, more flexible, and capital-efficient way to get professional results from day one.

Calculating the True Cost of DTF Printer Ownership

When you start shopping for a DTF printer, that initial sticker price is just the tip of the iceberg. The real financial picture—the total cost of ownership—includes the machine plus a whole ecosystem of ongoing expenses that can easily catch a new business owner off guard. Getting a handle on these numbers is the only way to figure out if this investment will actually make you money.

It's crucial to have a solid grasp of your shop's financial health before you even think about a major equipment purchase. Knowing how to How to Calculate Profit Margins for Your Business helps you see past simple revenue and understand what ongoing costs will do to your bottom line. Without that clarity, a seemingly "affordable" printer can quickly become a cash drain.

Beyond the Initial Purchase Price

That big upfront cost is the most obvious one, but it's never just about the printer. To get a fully functional setup off the ground, you need a few key pieces of gear, and each one has its own price tag.

- The Printer: You can find entry-level models starting around $800, but for something more reliable and built for steady work, you’re looking at $2,000 to $4,000.

- The Heat Press: This is non-negotiable. A quality heat press is essential for applying transfers correctly, and a reliable one will run you $300 to $800.

- Curing and Shaking Equipment: You’ll need a way to apply the adhesive powder and cure the ink. This could be a manual DIY setup or an automated shaker/oven combo, which adds another $500 to $1,500 (or more) to your initial bill.

Just with these core components, your startup costs can easily hit the $3,500 to $7,000 range—and that’s before you’ve even printed a single transfer.

Unpacking Recurring Consumable Costs

Once your equipment is humming, the meter starts running on consumables. These are the materials you’ll be buying over and over again to fill orders, and they directly impact your cost per print.

These costs scale directly with your production volume. A handful of shirts might seem cheap to produce, but when you're printing hundreds a month, these expenses add up fast. This is where outsourcing really shines; its predictable, per-print pricing makes financial planning a whole lot simpler.

The true cost of an in-house DTF setup isn't the machine—it's the constant drain of consumables, maintenance, and wasted materials. Many small businesses find that outsourcing transfers actually improves their profit margins by converting unpredictable operational costs into a simple, fixed expense.

With a service like Lion DTF, you can use our Auto-build gang sheet builder to pack as many designs as possible onto one sheet. This maximizes every inch of film and drops your per-design cost significantly—an efficiency that’s tough to match with your own setup, especially while you're still on the learning curve. For a deeper dive, check out our guide on how to price custom shirts for maximum profit.

The Hidden Costs of Operation and Maintenance

Beyond the big-ticket items and supplies, there are several "hidden" costs that often get missed in the initial budget. These operational expenses can eat into your profitability if you aren't prepared for them.

Operational and Maintenance Breakdown:

- Printhead Replacements: This is a big one. A printhead can cost anywhere from $300 to $1,200 to replace, and depending on your printer and how much you use it, you might be doing this every 6 to 18 months.

- Maintenance Supplies: Cleaning solutions, swabs, and other maintenance kits are a small but constant expense needed to keep your machine running smoothly.

- Ventilation: Curing powder creates fumes, so proper ventilation isn't optional—it's a safety requirement. This could be a simple fan or a full exhaust system, costing anywhere from $100 to $1,000.

- Electricity Consumption: Running a printer, shaker, curing oven, and heat press all at once will definitely make a dent in your utility bill.

- Wasted Materials: The learning curve for DTF is steep. In your first few months, expect to burn through a good amount of ink, film, and powder on misprints, clogs, and calibration tests.

When you add up the initial investment, the recurring supplies, and these hidden operational costs, the true price of owning a DTF printer becomes much clearer. It's a serious commitment of both cash and time that demands careful planning to see a real return.

The Smart Move: Why Outsourcing Your DTF Transfers Is a Strategic Advantage

Choosing to outsource your DTF printing isn't about compromise; it's a powerful strategic move that lets your small business punch well above its weight. It allows you to compete on quality and speed without sinking a huge chunk of capital into equipment. Instead of moonlighting as a printer technician, you can stay laser-focused on what actually grows your business—your designs, your marketing, and your customers.

Partnering with a specialist provider lets you sidestep the entire financial and operational headache of in-house production. What would have been a massive capital expense becomes a simple, predictable, and scalable variable cost. You pay for exactly what you need, when you need it, killing the pressure to constantly run jobs just to make a multi-thousand-dollar machine earn its keep. For most small businesses, this is the key to staying lean and agile.

Lock In Predictable Costs and Get Better Quality

One of the biggest wins of outsourcing is gaining total financial clarity. When you work with a pro like Lion DTF, your cost per print is locked in upfront. There are no surprise maintenance bills, no sudden need for a $1,200 printhead replacement, and no sleepless nights worrying about the rising cost of ink and film. For a small business managing cash flow, that kind of predictability is gold.

On top of that, you get immediate access to industrial-grade gear that’s way beyond the budget of most startups. Professional DTF providers run machines that cost tens of thousands of dollars, all perfectly calibrated for color accuracy and consistency. This means your transfers will have vibrant colors, crisp details, and a soft, durable feel from your very first order—letting you skip the expensive and wasteful learning curve that comes with any new in-house setup.

Maximize Every Dollar with an Auto-Build Gang Sheet Builder

Every small business owner knows that cost-effectiveness is the name of the game, and that's where the right tools make a world of difference. Our Auto-build gang sheet builder is designed to help you squeeze the absolute most value out of every single sheet. Instead of paying for each design individually, you can pack multiple logos, graphics, and jobs onto a single sheet.

This simple tool dramatically slashes your cost per transfer. By ganging up your print jobs, you can knock out orders for multiple clients or stock up on your best-sellers at once, all while paying for just one sheet. It's this kind of smart optimization that shows the true benefit of partnering with a provider focused on your bottom line. You can see more on how our DTF printing services are built to help you grow.

Outsourcing allows a small business to instantly tap into economies of scale. You get the quality and efficiency of a large-scale print operation without the capital risk, letting you compete with larger players on a level playing field.

The demand for custom apparel is exploding, and small businesses are right in the thick of it. In fact, small and medium-sized shops are the driving force behind the DTF printer market's projected 13% CAGR from 2023 to 2028. This growth, from $2.5 billion to $4.8 billion, shows just how many entrepreneurs are jumping on cost-effective, high-quality solutions for custom work. You can dig into more market insights over at Market Report Analytics.

Reclaim Your Most Valuable Asset: Time

Maybe the biggest, yet most overlooked, benefit of outsourcing is getting your time back. The reality of owning a DTF printer is that it’s a needy piece of equipment that demands constant attention.

A typical day for a printer owner includes:

- Morning Rituals: Running nozzle checks, cleaning capping stations, and shaking white ink to prevent clogs.

- Constant Troubleshooting: Figuring out why you're seeing banding, color shifts, or film feeding errors.

- Hands-On Production: Babysitting prints, applying powder, curing transfers, and keeping track of all your consumables.

- Never-Ending Homework: Staying on top of firmware updates, software tweaks, and new maintenance tricks to keep the machine from becoming a giant paperweight.

When you outsource, all of those operational headaches vanish. The hours you would have spent wrestling with a printer can be poured back into activities that actually make you money: creating killer new designs, engaging with your audience on social media, or building new partnerships. You get to shift from being a machine operator back to being a business owner—and that’s everything when it comes to sustainable growth.

Head-to-Head Comparison: Key Decision Factors

Deciding between buying your own DTF printer and outsourcing your transfers is a huge crossroads for any small business. To make the right call, you have to look past a simple pros-and-cons list and really dig into the factors that will shape your daily operations, your finances, and your ability to grow.

This head-to-head comparison is designed to give you a clear framework for that decision. We'll evaluate each path across the metrics that actually matter: production speed, quality control, the true cost per print, and the operational demands that often get overlooked.

Production Speed and Scalability

On paper, owning the printer gives you the advantage of instant, on-demand production. Need a single shirt printed right now? You can do it. But that "instant" speed is often an illusion. It doesn't factor in the daily setup, the cleaning rituals, or the troubleshooting that can bring everything to a grinding halt. A simple clog can turn a 10-minute job into a two-hour headache.

Outsourcing, on the other hand, offers something more valuable: predictable and scalable speed. While you don't get a print the second you need it, a reliable partner like Lion DTF ships orders in just 1-2 business days. That consistency is gold because it lets you set realistic deadlines for your customers. When your orders jump from ten shirts a week to a hundred, your workflow doesn't change—you just place bigger orders. That's effortless scalability, and it’s a game-changer for a growing business.

For a small business, true speed isn't about how fast a single print is made. It's about the total time from order placement to a happy customer. Outsourcing eliminates the unpredictable delays of in-house maintenance, often resulting in a faster and more reliable overall turnaround.

Color Consistency and Quality Control

Owning a printer puts you in the driver's seat for quality control. You can tweak color profiles and ink density to your heart's content, which is a big plus if you have the technical skills to dial everything in perfectly. But it also means you’re the one on the hook when things go wrong. Color shifts, banding, and patchy white ink layers become your problem to solve, often under a tight deadline.

Getting that professional-grade quality consistently requires a deep understanding of RIP software and, just as importantly, a controlled environment. A change in humidity or temperature can completely throw off your print results.

When you outsource to a specialist, you're buying into their investment in industrial-grade equipment and expert technicians. At Lion DTF, our printers operate in climate-controlled facilities and are calibrated daily to guarantee color accuracy. This ensures that an order you place today will have the exact same vibrant, consistent colors as one you place six months from now—no steep learning curve required.

The True Cost Per Print

Calculating your real cost per print with an in-house setup is a lot more complicated than it seems. You have to account for ink, film, and powder, but don't forget electricity, wasted materials from test prints and misprints, and the amortization of the printer itself. And then there are the parts. A $1,200 printhead that lasts a year adds over $100 per month to your baseline costs before you even print a single transfer.

Outsourcing makes this calculation simple. Your cost per print is a fixed, predictable number. That clarity is invaluable for budgeting accurately and pricing your products for real profit.

Even better, using a tool like our Auto-build gang sheet builder completely changes your cost model. It intelligently arranges multiple designs on a single sheet, squeezing the most value out of every square inch of film and drastically cutting the cost of each individual design. This creates an economy of scale that's nearly impossible for a small in-house setup to match. For more tips on this, our guide to modern t-shirt printing offers some great insights.

Maintenance and Downtime Demands

The single biggest hidden "cost" of owning a DTF printer is the time you'll spend on maintenance. It's not a suggestion; it's a requirement. Daily tasks include shaking white ink, cleaning capping stations, and running nozzle checks. Then there are the weekly and monthly deep cleans and parts inspections. Skipping these steps is a fast track to clogged printheads and expensive repairs.

All that maintenance adds up to hours each week that you aren't spending on designing, marketing, or talking to customers. Worse, when a printer goes down, your entire business stops. An unexpected breakdown can leave you unable to fulfill orders for days, which can seriously damage your reputation and your revenue.

Outsourcing removes this entire burden from your shoulders. There is zero maintenance and zero downtime to worry about. The provider handles all the equipment upkeep, so their machines are always running. This frees you up to focus 100% of your energy on what you do best: building your brand, confident that your production is in reliable hands.

Detailed Feature Comparison: Owning a Printer vs. Using Lion DTF Transfers

To see all these factors side-by-side, it's helpful to break them down into a clear comparison. The table below outlines the practical differences you'll experience between running your own equipment and partnering with a dedicated transfer provider.

| Evaluation Criterion | Owning a DTF Printer | Outsourcing to Lion DTF Transfers |

|---|---|---|

| Initial Investment | High ($3,000 - $20,000+) for printer, software, and setup | $0 - No equipment purchase needed |

| Production Speed | Instant for single prints, but variable due to maintenance/repairs | Predictable 1-2 business day turnaround, consistent at any scale |

| True Cost Per Print | Complex and variable (ink, film, powder, waste, electricity, parts) | Fixed and predictable, optimized with gang sheets |

| Quality Control | Full control, but requires significant technical expertise & environment control | Professional-grade consistency; daily calibration in controlled facilities |

| Maintenance Burden | Daily, weekly, and monthly tasks required (5-10 hours/week) | Zero - All maintenance is handled by the provider |

| Risk of Downtime | High; a single component failure can halt all production | Zero - Production is guaranteed, backed by multiple machines |

| Scalability | Limited by the output of a single machine; requires more equipment to grow | Effortless; order volume can scale from 1 to 10,000+ with no change in your workflow |

| Space & Environment | Requires dedicated, ventilated space with climate control | No physical footprint required for your business |

| Learning Curve | Steep; requires training on RIP software, maintenance, and color management | None; simply upload your designs and place an order |

This comparison highlights a clear trade-off: owning a printer offers ultimate control at the cost of high investment, steep learning curves, and significant operational burdens. Outsourcing, in contrast, offers simplicity, predictability, and scalability, allowing you to focus entirely on growth.

Which Path Makes Sense? Real-World Scenarios

Theory is one thing, but seeing how this decision plays out for real businesses is what truly matters. Let's walk through a few common scenarios to make the choice between buying a DTF printer and outsourcing your transfers feel less abstract.

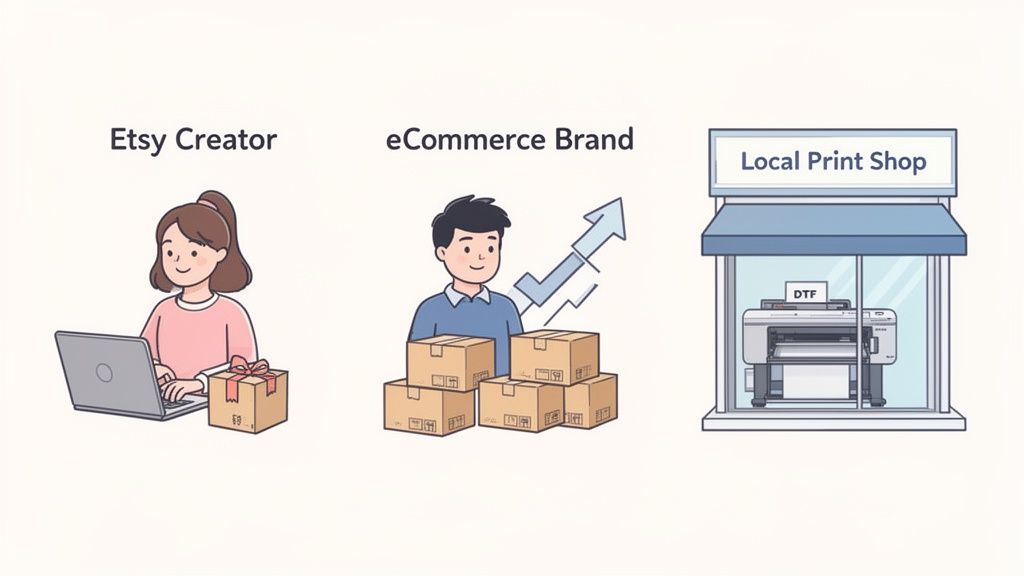

By looking at these relatable examples—an Etsy creator, a growing eCommerce brand, and an established print shop—you can probably see a bit of your own business in one of them. Each one is under different pressures, and the "right" answer is definitely not the same for all three.

The Etsy Creator with Unpredictable Sales

First up is Sarah. She runs a popular Etsy shop selling custom t-shirts and tote bags. Her sales are a classic roller-coaster; one week she might get slammed with 50 orders for a design that suddenly went viral, but the next two weeks could be dead silent with just a couple of sales trickling in. Her entire operation is run out of a spare bedroom, and every dollar counts.

For Sarah, dropping thousands on even an entry-level DTF printer is a huge gamble. The upfront cost alone would wipe out her working capital. More importantly, the constant maintenance would become a massive headache during those slow periods. A printer that isn’t running is a liability—idle white ink is the number one cause of expensive, business-killing printhead clogs.

Recommendation: Outsource

For Sarah, outsourcing is a no-brainer. It transforms a major capital expense into a small, manageable variable cost. She only orders transfers when she has paid orders in hand, which completely eliminates waste and protects her cash flow.

For a business with inconsistent order flow, outsourcing is not just a convenience—it's a financial lifeline. It provides access to professional quality without the risk and operational burden of owning equipment that may sit unused for weeks at a time.

Using our Auto-build gang sheet builder is tailor-made for her business model. She can easily combine designs for multiple small orders onto a single sheet. This keeps her per-print cost incredibly low and her profit margins healthy, even when sales are slow. It gives her the agility to jump on trends without being weighed down by a depreciating piece of equipment.

The Growing Ecommerce Brand Trying to Scale

Next, let's look at Alex, who runs a successful online apparel brand. He's got a steady stream of 30-50 orders coming in every single day and is laser-focused on growth. For him, speed is key. He needs to get orders out the door fast, maintain tight quality control, and be able to create one-off samples for new designs instantly. He has some capital to invest and a dedicated corner in his garage for production.

The idea of owning a printer is tempting for Alex. The control and on-demand capability seem like the logical next step. But the reality of operating it presents a serious bottleneck. Every hour spent on daily maintenance, troubleshooting jams, or shaking ink cartridges is an hour not spent on marketing, customer service, or developing new products—the very activities that fuel his brand's growth.

Recommendation: A Hybrid Approach, Starting with Outsourcing

Alex's order volume is getting close to the point where a printer might seem logical, but his most valuable asset right now is his time. The smartest move is to start by outsourcing to a reliable partner like Lion DTF. This locks in consistent quality and predictable turnaround times, freeing him up to actually scale the business. This strategy is made even more cost-effective by using our Auto-build gang sheet builder, which allows him to combine his daily orders to maximize film usage and reduce costs.

Once his volume is consistently hitting over 1,000+ prints per month and he can justify hiring a dedicated person to run the machine, then it makes sense to invest in a high-quality printer. This hybrid strategy allows him to grow efficiently without killing his momentum.

The Local Print Shop Looking to Expand

Finally, we have an established local screen printing shop. They want to start offering full-color, small-batch printing to their clients. They already have the physical space, a trained staff, and a steady flow of B2B customers who are constantly asking for smaller, more detailed jobs that are just not profitable to set up on a screen printing press. Their main goals are to integrate a new service smoothly and make sure it's profitable from day one.

Recommendation: Buy a Printer

This is the perfect scenario for purchasing a DTF printer. The shop already has the existing infrastructure and, most importantly, the customer base to make the investment pay off quickly.

A professional-grade DTF printer would let them say "yes" to all those jobs they've been turning away, capturing revenue that was previously walking out the door. The printer isn't a gamble; it's a new profit center from the moment it's installed, complementing their core services and expanding what they can offer their market. They have the staff to handle the upkeep and the order volume to guarantee a fast return on their investment.

Your Final Verdict: A Checklist to Help You Decide

Making the right call between buying a DTF printer and just ordering transfers comes down to a really honest look at where your business is right now. Not where you want it to be in a year, but today.

We've covered a lot of ground, so I've boiled it all down into a straightforward checklist. Use this to get some real clarity on the most logical and profitable path for you. There are no right or wrong answers here—only what’s best for your situation.

Your Decision-Making Checklist

-

What's your real, consistent monthly order volume?

- Under 100 prints: Your volume is still building and likely inconsistent. Outsourcing is easily the lowest-risk and most cost-effective way to go.

- 100-500 prints: You've got steady demand, which is great! Outsourcing is still incredibly efficient at this stage, but you could start to consider a printer if you have the cash and time for the upkeep.

- Over 500 prints: Okay, now you're in the zone where owning a machine might make financial sense, as long as you can genuinely handle the day-to-day operational side of things.

-

What's your actual budget for the full setup?

- Under $3,000: Outsourcing is your only real option. That budget just won't cover a reliable printer, a quality heat press, and all the initial supplies you'll burn through.

- $3,000 - $7,000+: You're in the ballpark for a quality entry-level or mid-range setup. The question now becomes: is that investment worth it compared to the simplicity of ordering transfers as you need them?

-

How much time can you honestly commit to maintenance each week?

- Less than 5 hours: Stick with outsourcing. I can't stress this enough. Printer ownership demands daily and weekly attention that will eat up way more time than this.

- More than 5 hours: You might have the time, but the real question is whether that time is better spent on marketing, sales, and growing your brand.

For most small businesses, the honest answers to these questions point directly toward outsourcing. It offers a risk-free way to get started with professional-grade quality, turning a massive operational headache into a simple, scalable business expense.

Ultimately, the goal is growth. Partnering with a provider lets you tap into tools like our Auto-build gang sheet builder to maximize every dollar right from day one. It’s built to make your workflow simple and cost-effective, freeing you up to focus on what really matters: building a brand that people love.

Answering Your Top Questions

Deciding between buying your own DTF printer and using a service like ours usually comes down to a few key questions. Let's tackle the most common ones we hear from businesses trying to find the right path.

When Does It Really Make Sense to Buy a DTF Printer?

There isn't a single magic number for everyone, but here’s a good rule of thumb: start thinking about it when you consistently spend more on transfers each month than what you'd pay to finance and run your own machine. For most solid entry-level printers, that tipping point often hits when you're cranking out several hundred full-size shirt designs a month.

But—and this is a big one—that math has to include the value of your time. Many growing businesses find that even at higher volumes, outsourcing is still more profitable. Why? Because it completely removes the time you'd sink into maintenance, troubleshooting, wasted materials, and surprise downtime. That's time you could be using to sell more shirts and grow your brand.

How Much Space Do I Actually Need for a Full DTF Setup?

It's easy to underestimate the real footprint of a DTF operation. You’re not just making room for a printer; you need a whole workflow. A proper in-house setup requires dedicated space for:

- The printer itself (which can easily be 3-5 feet wide)

- A separate station for powdering and shaking

- A curing oven (or a heat press you dedicate to curing)

- Storage for your supplies like film rolls, inks, and big bags of powder

The most critical part? The entire area needs great ventilation to handle the fumes from curing the adhesive. Realistically, a dedicated, climate-controlled room of at least 10x10 feet is the minimum you should plan for to work safely and efficiently.

Can I Use an Auto-Build Gang Sheet Builder Without Fancy Design Software?

Yes, absolutely! This is one of the best things about using a modern Auto-build gang sheet builder. It’s built for accessibility. You can upload your individual art files—like PNGs with transparent backgrounds—straight into the tool.

The builder then does the heavy lifting, automatically arranging everything to pack as much as possible onto the film. This means you’re not wasting an inch of material, which saves you money on every single print. You don't need to be a pro with Adobe Photoshop or Illustrator to create a perfectly optimized, print-ready gang sheet.

Ready to skip the headaches of owning a printer and just get amazing transfers delivered to your door? Lion DTF Transfers delivers vibrant, tough-as-nails prints with a fast, reliable turnaround. Free up your time and boost your profits with a service that just works. Explore our DTF transfers today!