In the world of custom branding and crafts, you’ve probably heard the buzz around UV DTF wraps. Think of them as next-level permanent decals built for hard surfaces like glass, metal, and plastic—and the best part? No heat press is required. They use a slick combination of UV-cured ink and a seriously strong adhesive to create durable, slightly raised designs that have a professional, almost painted-on look.

Unpacking the Buzz Behind UV DTF Wraps

If you've noticed a surge in stunning, full-color designs popping up on everything from coffee mugs to phone cases, you've likely seen UV DTF wraps in action. This technology has quickly become a favorite for small businesses, crafters, and promo companies for one simple reason: it delivers premium results without the usual headaches.

Unlike vinyl decals that make you spend ages weeding tiny pieces, or screen printing with its messy setups, UV DTF wraps arrive ready to go. The process is as straightforward as it gets: peel, stick, and rub. What you’re left with is a vibrant, scratch-resistant, and water-resistant graphic that’s permanently bonded to the object.

The Core Appeal for Modern Creators

So, what’s making everyone switch over? It really boils down to a few key advantages that solve the common pain points anyone making custom products faces.

- No Heat Necessary: This is the big one. You can finally decorate heat-sensitive items like certain plastics, acrylics, or electronics without worrying about melting or damage.

- Exceptional Detail and Color: UV DTF can reproduce photorealistic images, complex logos, and smooth gradients with incredible clarity and pop—something that’s notoriously difficult to pull off with layered vinyl.

- Durability for Daily Use: These designs are tough. Once applied, the ink and adhesive form a resilient layer that stands up to handling, making it perfect for items people use every single day.

- Versatility Across Materials: From glass and metal to sealed wood and ceramics, these wraps stick to a massive array of non-porous surfaces, opening up a whole new world of creative possibilities.

The real magic of UV DTF is how it empowers creators. It gives you the ability to produce high-end, professional-quality goods on demand, without needing a workshop full of expensive equipment. It’s a direct path from a digital design to a physical product that looks and feels premium.

For a quick overview, here are the key features that define UV DTF wraps.

UV DTF Wraps at a Glance

| Attribute | Description |

|---|---|

| Application Method | Peel-and-stick; no heat required. |

| Surface Compatibility | Hard, non-porous surfaces (glass, metal, plastic, wood, etc.). |

| Durability | High resistance to scratches, water, and UV fading. |

| Appearance | Slightly raised, glossy, "painted-on" look with vibrant color. |

| Best For | Logos, detailed graphics, and full-wrap designs on drinkware. |

| Weeding Required? | No, designs are printed and ready to apply. |

This table shows just how much this technology simplifies the customization process while delivering top-tier results.

Market Growth and Accessibility

This isn't just a niche trend; it's backed by some serious market growth. The global UV DTF market was valued at an impressive US$215 million in 2024 and is projected to hit US$442 million by 2031. This boom is being fueled by small businesses and e-commerce sellers who need reliable, high-quality ways to customize their products.

And the best part? You don’t need to invest in a printer yourself to get started. Services like ours make it incredibly simple to bring your ideas to life. With our Auto-build gang sheet builder, you can upload multiple designs, arrange them to get the most out of your sheet, and see just how cost-effective your project can be. This tool makes creating custom UV DTF wraps both accessible and affordable, whether you're making one-off gifts or a batch of a hundred for your shop.

To dive deeper, you can explore our full guide on UV DTF technology for more in-depth information.

How Are UV DTF Wraps Actually Made?

Ever see a mind-blowing, full-color design on a glass cup or metal water bottle and just wonder… how? The magic behind UV DTF wraps is a cool, multi-layered process that takes a digital file and turns it into a tough, ready-to-slap-on transfer. It’s way less complicated than it sounds, and the best part? No heat is involved.

Picture it like building a high-tech sticker, layer by layer. Each part has a very specific job, and they all come together to create that final, pop-of-color design. The whole journey happens on a special sheet of plastic called the A-film, which is basically the temporary workspace for your art.

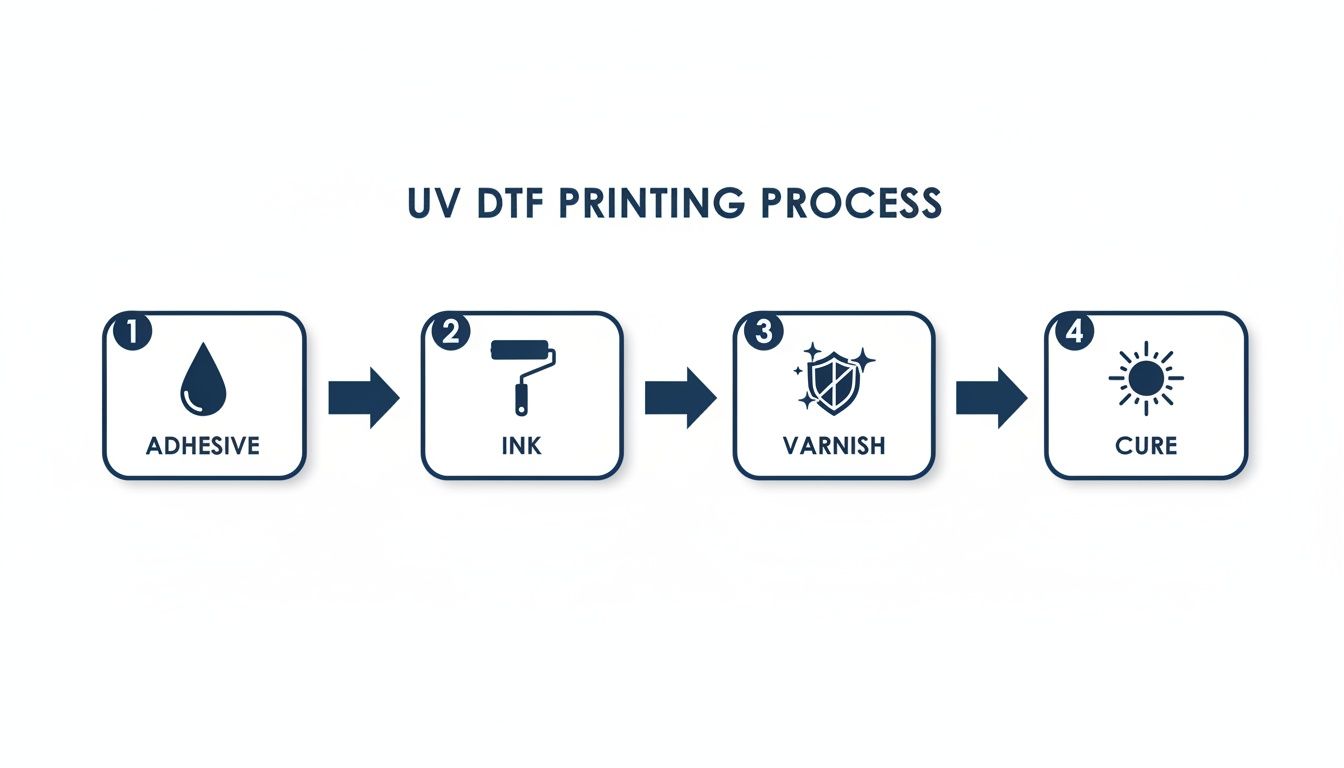

The Layers That Build the Transfer

The process kicks off with a specialized UV DTF printer—this isn't your standard office machine. It doesn't just lay down color; it literally builds the transfer from the sticky side up.

- The Glue Layer: First things first, the printer puts down a perfectly clear layer of specialized adhesive glue, cut exactly to the shape of your design. This is the foundation that’s going to grab onto the product for dear life.

- The White Ink Base: Next up is a solid layer of opaque white ink printed right on top of that glue. Think of it like a coat of primer on a dark wall. This white base guarantees your colors will look bright and punchy, no matter what color surface you’re sticking the wrap on.

- The Color Ink: With the white base ready, the printer meticulously adds the color ink (cyan, magenta, yellow, and black). This is where your digital design springs to life, as the machine nails every detail, gradient, and shade with crazy precision.

This layering technique is exactly what gives UV DTF its knockout visual punch. That white underbase is the secret sauce ensuring your design looks just as awesome on a black tumbler as it does on a clear mug.

Curing and Finishing Touches

Once the inks are down, the most important step happens in a flash. As the film moves through the printer, it gets blasted by a powerful UV lamp.

This is the “UV” in UV DTF. The ultraviolet light instantly cures—or hardens—the ink and adhesive, locking all the layers together into a single, durable film. There’s no waiting around for it to dry, which makes the whole process incredibly fast.

The last touch is a protective layer of varnish that the printer applies over the entire design. This glossy topcoat doesn't just add a professional sheen; it acts as an extra shield against scratches, water, and sun, which is a big reason UV DTF wraps last so long.

After printing, a second sheet, called the B-film or carrier film, is laminated over the top. This B-film is what holds your finished design, letting you peel it away from the A-film backing when you’re ready to apply it. You’re left with a perfect, ready-to-stick transfer of just your design—no clear background, and absolutely no weeding.

This efficient, layer-by-layer method is also what lets us crank out a ton of different designs on one big sheet. When you use our Auto-build gang sheet builder, you’re taking full advantage of this. By arranging all your logos and graphics onto a single sheet, you maximize your print area, cut down on waste, and get way more bang for your buck. This ease of use makes it simple to order cost-effective custom transfers for any project you’ve got going on.

UV DTF Wraps vs. Vinyl Decals: Which Is Better for Your Project?

When you need to put a custom design on a hard surface, you'll probably land on two main choices: UV DTF wraps or classic vinyl decals. And while both can stick a graphic onto something, they're worlds apart in how they're made and what they're best for. Knowing where each one shines will help you nail your project the first time.

For years, vinyl decals have been the default for simple graphics. Think single-color lettering for a storefront, basic logos, or silhouette-style shapes. The process is pretty hands-on: a machine cuts your design from a sheet of colored vinyl, and then you have to manually "weed" away all the extra bits before you can apply it. This makes vinyl a decent option for straightforward, uncomplicated art.

UV DTF wraps, on the other hand, play a completely different game. They were born for creating detailed, full-color, and even photorealistic graphics without any of the tedious manual labor. Instead of cutting and weeding, a UV DTF transfer is printed as a single, cohesive piece that's ready to apply, preserving every tiny detail, color gradient, and subtle texture from your original design.

The Weeding-Free Advantage

The single biggest reason people switch to UV DTF wraps is that you can say goodbye to weeding forever. If you've ever spent what feels like an eternity hunched over a piece of vinyl, picking out tiny, intricate pieces with a sharp tool, you know this is a massive deal.

- Complex Designs: Got a logo with super fine lines, a detailed illustration, or a pattern with dozens of colors? Weeding that on vinyl isn't just a headache—it’s often impossible without tearing the design or losing important details. UV DTF handles these jobs effortlessly.

- Time Savings: The hours saved by skipping the weeding step are huge, especially if you’re a business cranking out products in bulk. That efficiency means you can finish more orders in less time.

- Perfect Results Every Time: With UV DTF, what you see on the screen is exactly what you get on the product. There's zero risk of accidentally ripping a small piece of the design or leaving behind a stray bit of vinyl during the weeding process.

This "no-weeding" magic is all thanks to the layered printing process, where adhesive, ink, and a protective varnish are applied in a precise sequence.

As you can see, each layer is applied perfectly, creating a single, unified transfer where only your design sticks to the final product.

To really see the difference, let's put them side-by-side.

Feature Comparison UV DTF Wraps vs Vinyl Decals

| Feature | UV DTF Wraps | Traditional Vinyl Decals |

|---|---|---|

| Design Complexity | Excellent for full-color, intricate, and photorealistic designs. No limits on detail. | Best for simple, single-color shapes, text, and basic logos. |

| Application Process | Print, peel, and stick. No weeding required. | Cut, weed excess material by hand, then apply with transfer tape. |

| Durability | Highly resistant to scratches, water, and UV fading. Permanent bond. | Good durability but can peel at the edges over time. Prone to scratching. |

| Finish | Slightly raised, glossy, "painted-on" look. Premium feel. | Flat, matte, or glossy finish. Looks like a high-quality sticker. |

| Speed for Bulk Orders | Much faster due to the elimination of weeding. | Very time-consuming for complex designs or large quantities. |

| Best For | Drinkware, phone cases, laptops, equipment branding, complex logos. | Window lettering, wall decals, simple vehicle graphics, signage. |

This table makes it clear: if your design is complex or you need top-tier durability, UV DTF is the superior choice.

Comparing Durability And Finish

Beyond just the application, the final look and feel really set these two apart. A vinyl decal, while tough, is still just a thin layer of plastic stuck to a surface. It can sometimes start to peel up at the edges over time and is more likely to get scratched, especially on things you handle a lot.

In contrast, a UV DTF wrap creates a permanent bond. The cured ink and varnish form a durable, slightly raised layer that has a premium, almost painted-on look and feel. This finish is built to last, offering excellent resistance to scratches, water, and fading from the sun. That makes it the perfect choice for high-contact items like tumblers, phone cases, and branded equipment.

For a deeper dive into how this technology compares to other decoration methods for fabric, check out our guide on the differences between DTF and heat transfer vinyl. While that article focuses on apparel, the principles of durability and design freedom carry over.

Creative Ways to Use UV DTF Wraps

This is where the real fun with UV DTF wraps begins. Theory is one thing, but seeing them in action is another. Their versatility opens up a huge range of creative and commercial doors for both businesses and hobbyists. It’s all about transforming everyday objects into premium, customized products that grab attention and are worth more.

This technology lets you add durable, full-color graphics to items that were once a serious pain—or just plain impossible—to decorate. Since there’s no heat involved and the application is a simple peel-and-stick process, the list of what you can customize is nearly endless.

Branding for Businesses and Events

One of the most powerful uses for these wraps is in corporate and event branding. Being able to produce vibrant, permanent logos on demand makes UV DTF a game-changer for creating sharp, professional-looking merch.

Take a construction company that needs to brand a fleet of hard hats. With UV DTF wraps, they can apply a complex, multi-color logo that’s tough enough to handle job site abuse. The result is a scratch-resistant finish that looks way more professional than a basic sticker could ever hope to.

This same idea works for tons of other scenarios:

- Corporate Gifting: Personalize tech gear like laptops, power banks, and wireless chargers with company logos for employee or client gifts.

- Event Merchandise: Create custom 16oz cup wraps for a wedding, festival, or corporate retreat, turning simple drinkware into a cool keepsake.

- Retail and Hospitality: Brand point-of-sale equipment, menu boards, or even reserved signs for a polished, cohesive look.

The real win here is consistency and quality. UV DTF ensures that a brand’s logo looks crisp and identical across all sorts of materials, from the plastic on a hard hat to the metal on a travel mug.

The custom drinkware market, especially, has blown up. UV DTF cup wraps have become a hot seller in the wholesale space, with demand spiking around the holidays. This trend can lead to 42-58% higher retail prices compared to items with standard prints, all thanks to their premium look and feel. Big suppliers have noted that durable films are crucial, with some brands capturing as much as 37% of the UV DTF cup wrap market for popular 16oz cups. You can learn more about the trends in the wholesale UV DTF cup wrap market to see for yourself.

High-Value Personalization and Crafts

For crafters and small e-commerce shops, UV DTF wraps open the door to creating high-value, personalized products without having to invest in a ton of expensive equipment. The level of detail you can get allows for intricate, artistic designs that really pop.

Think about an artist selling their work online. Now they can transfer their detailed illustrations onto phone cases, notebooks, or even musical instruments, creating a completely new line of merchandise. The wraps capture every single brushstroke and color gradient perfectly, keeping the integrity of the original art intact.

Here are a few more ideas to get you started:

- Custom Sports Gear: Apply team logos, player numbers, and sponsor graphics to helmets, bats, skateboards, and water bottles. The durable finish holds up to the wear and tear of active use.

- Unique Home Décor: Decorate ceramic vases, glass canisters, or wooden plaques with custom patterns or quotes for a personalized touch.

- Specialized Machinery: Add permanent labels, instructions, or branding to industrial equipment or toolboxes, making sure the information stays readable even in tough environments.

What makes all of this so doable is how easy and cost-effective it is to order. Using our Auto-build gang sheet builder, you can upload dozens of different designs—large logos for laptops, small ones for phone cases, and full wraps for cups—all on a single sheet. This maximizes every inch of material and slashes your cost per piece, making it profitable to produce everything from one-off custom items to large batches for your business.

Applying Your UV DTF Wraps for a Perfect Finish

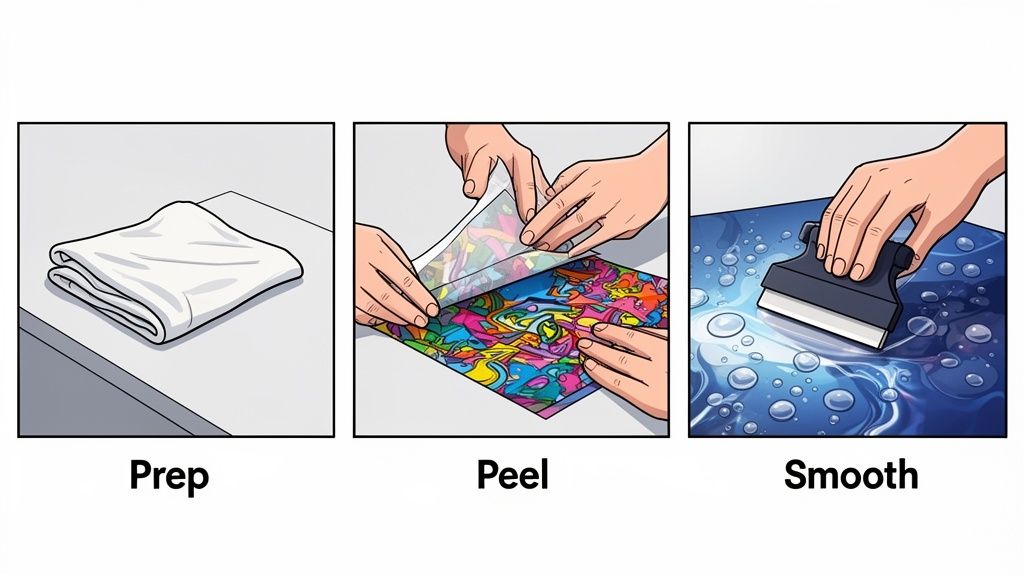

Getting a flawless, professional look with your UV DTF wraps is way easier than you might think. Unlike other methods that need heat presses or special tools, this is a simple peel-and-stick transfer. That said, a little prep work and the right technique will make sure your designs stick perfectly and look like they were painted on every single time.

The secret is a clean surface and steady pressure. Think of it like applying a high-end decal—you want to get rid of anything that could get in the way of the adhesive's bond.

The Step-by-Step Application Process

Follow these four simple steps for a perfect finish. Taking your time here really pays off with a durable, long-lasting design that looks incredible.

- Prepare the Surface: This is the most critical step. Clean the object thoroughly with rubbing alcohol and a lint-free cloth to wipe away any dust, oils, or fingerprints. The surface has to be completely dry before you move on.

- Peel the Backing: Carefully peel the white paper backing away from the clear carrier film. Your design will stay on the sticky side of the clear film, ready to go.

- Position and Apply: Take your time aligning the transfer on your item. Once you're happy with the placement, press it down firmly, starting from the center and working your way out to push out any air bubbles.

- Secure and Finish: Grab a squeegee or just use your thumb to rub over the entire design with firm, even pressure. This makes sure every bit of the adhesive makes solid contact. Finally, slowly peel off the clear carrier film at an angle to reveal your finished design.

This simple process is what makes UV DTF wraps so user-friendly. No heat, no mess—just a clean, vibrant result.

Pro Tips for Flawless Results

Even though the process is straightforward, a few expert tips can help you master the application and avoid common mistakes. Keeping these in mind will take your finished products from good to great.

- Avoid Porous and Textured Surfaces: For the strongest bond, stick to smooth, hard, non-porous materials like glass, metal, plastic, and sealed wood. You'll want to avoid fabrics, silicone, rubber, or heavily textured surfaces where the adhesive can’t get a good grip.

- Let It Cure: After applying the wrap, let the adhesive cure for at least 24 hours before washing or heavy use. This gives the bond time to reach its maximum strength, ensuring it holds up.

- No Overlapping: If your design has multiple pieces, avoid overlapping the wraps. The adhesive is made to stick to the product surface, not to another wrap, and layering can cause peeling down the road.

The key is patience. Rushing the placement or yanking the carrier film off too quickly can create imperfections. Take a moment to line everything up, and you'll be rewarded with a perfect transfer.

Caring for Your Decorated Items

To get the most life out of your custom creations, a little care goes a long way. The tough varnish and adhesive used in UV DTF wraps make them highly water-resistant and durable, but they aren't indestructible.

For decorated drinkware like mugs and tumblers, hand-washing is always recommended. Try not to use abrasive sponges or scrub brushes directly on the design. While the wraps are tough, the high heat and harsh detergents in a dishwasher can weaken the adhesive over time. Follow these simple care instructions, and your custom designs will stay vibrant and intact for years.

How to Order Your Custom Transfers—The Easy Way

Getting your designs from a file on your computer to a finished, ready-to-apply transfer should be the exciting part, not a chore. We've built our entire ordering system around that idea. It’s simple, puts you in the driver's seat, and makes sure you don’t run into any headaches along the way.

We get it—whether you're making a one-off custom gift or running a full-scale production for your business, time and money matter. Our goal is to save you both, which is why we've put some seriously powerful tools right at your fingertips.

Maximize Value with Our Gang Sheet Builder

The real hero of our ordering process is the Auto-build gang sheet builder. Think of it as your secret weapon for getting the most bang for your buck on professional UV DTF wraps. This tool lets you upload as many designs as you want—all different sizes, shapes, and colors—and fit them all onto one sheet, making it exceptionally easy to use and cost-effective.

Let's say you need a bunch of different things: some logos for phone cases, a few full wraps for 16oz cups, and a handful of small decals for keychains. Instead of juggling multiple orders, you just do this:

- Upload All Your Designs: Just drag and drop every print-ready file you have into the builder.

- Arrange and Optimize: Move each design around to fill up the sheet, making sure there's as little wasted space as possible.

- See Instant Savings: As you fill the sheet, the cost is calculated right there on the screen. You'll see exactly how much you're saving by packing everything together.

Using this method slashes your cost per transfer, making it incredibly affordable to produce a whole variety of custom items at once. For a full breakdown, check out our guide on how to build a UV DTF gang sheet on the blog.

Our whole philosophy is making pro-level customization accessible to everyone. The gang sheet builder isn't just a tool; it's a clear, straightforward path to getting high-quality transfers without breaking the bank.

Quality and Support You Can Count On

A simple ordering process is great, but it means nothing if the final product doesn't live up to your standards. We back up our easy ordering with a serious commitment to quality. Our advanced color-matching tech ensures your designs come out looking vibrant and sharp—exactly like you imagined them. Your finished UV DTF wraps will have the rich colors and crisp details needed to make your products pop.

On top of that, we know you need your orders fast. We offer quick shipping options to get your transfers in your hands right when you need them. Combine that with a customer support team that's actually here to help, and you’ve got a partner ready to handle your custom transfer needs without any of the usual production drama. From the first click to the final peel, we’re here to make sure it all goes smoothly.

Got Questions About UV DTF Wraps?

As you start digging into what UV DTF wraps can do, it’s natural for a few questions to come up. Getting straight answers on the practical stuff is key to making sure your projects look amazing every single time. Let's tackle some of the most common ones.

Are UV DTF Wraps Waterproof and Dishwasher Safe?

This is easily one of the first things people ask, especially when it comes to drinkware. The short answer is yes, UV DTF wraps are highly water-resistant. They’re a fantastic choice for things like tumblers, mugs, and water bottles that see a lot of moisture. The cured ink and super-strong adhesive hold up beautifully against daily handling and hand-washing.

But here's a crucial tip: keep them out of the dishwasher. The high heat and harsh detergents are just too aggressive and can break down the adhesive over time. To keep your wrap looking perfect for the long haul, a gentle hand-wash is all it needs.

Can I Apply a UV DTF Wrap to Any Surface?

While these wraps are incredibly versatile, they definitely have their favorite surfaces. For that rock-solid, permanent bond, you want to stick to smooth, hard, non-porous materials. Think glass, metal, hard plastics, ceramics, and wood that’s been sealed—these are the perfect canvases.

On the flip side, there are a few materials you’ll want to avoid because the adhesive just won't get a good grip. Stay away from:

- Fabrics and textiles like t-shirts or hats.

- Soft, squishy materials like silicone or rubber.

- Porous or rough surfaces like raw wood or anything with a powder-coated finish.

Stick to the right surfaces, and you'll get a flawless application that’s built to last.

What Is the Difference Between Regular DTF and UV DTF?

This one trips a lot of people up. They sound similar, but regular DTF and UV DTF are completely different tools for different jobs. Knowing which is which is essential for picking the right product.

Regular DTF (Direct-to-Film) is made exclusively for fabrics—think t-shirts, hoodies, and bags. It uses a heat press to transfer the ink from the film onto the garment. UV DTF, on the other hand, is a no-heat, adhesive-based transfer designed only for hard goods. It acts more like a premium, permanent decal or sticker.

So, if you’re decorating apparel, you need regular DTF. For hard items like mugs, laptops, or phone cases, UV DTF wraps are the way to go.

Ready to bring your own custom designs to life? At Lion DTF Transfers, we make it simple to get professional-quality transfers without the hassle. Our intuitive Auto-build gang sheet builder empowers you to arrange multiple designs on one sheet, maximizing value and minimizing waste. Experience vibrant colors, fast shipping, and reliable support for your next project.