When you’re figuring out the best way to make custom apparel, you’ll eventually land on a big question: screen print transfers or DTF transfers? Both are solid, professional methods for creating durable designs, but they get there in completely different ways. Those differences will affect everything from your upfront costs to your creative freedom.

Getting a handle on how each one works is the first step to making a smart choice for your business.

Choosing the Right Custom Apparel Transfer Method

Picking a transfer technology isn't just a production detail—it defines what your business can offer, how your final products feel, and what your profit margins look like.

For years, traditional screen print transfers have been the industry go-to. They're known for being tough and incredibly cost-effective, but only when you're printing in high volumes. On the other side, you have modern DTF transfers, which bring total creative freedom to the table. We’re talking full-color, photorealistic printing with absolutely no minimum order quantities.

This guide will break down these two powerhouse methods so you can decide which one truly fits your needs. To get even more context on how different print methods stack up, check out our detailed guide on DTF vs DTG printing.

Core Differences at a Glance

Before we dive deep, let's start with a high-level look. Each method has its own sweet spot, and knowing their strengths is key.

| Feature | Screen Print Transfers | Direct-to-Film (DTF) Transfers |

|---|---|---|

| Best For | Large runs of simple, one-to-two color designs. | Small to large runs with complex, multi-color designs. |

| Color Capability | Limited spot colors per design. | Unlimited colors, gradients, and photorealism. |

| Setup Cost | High initial setup (screens, films per color). | No setup cost; designs are printed directly. |

| Fabric Feel | Thicker, classic plastisol feel on the garment. | Lightweight, soft, and flexible on the fabric. |

The deciding factor often comes down to two things: order volume and design complexity. Screen printing is the king of efficiency when you need to print hundreds of the same one-color logo. DTF, however, shines when you need to fulfill ten different full-color designs without breaking a sweat.

This trade-off is really at the heart of the comparison—volume-based efficiency versus on-demand flexibility. For businesses that need to produce a wide variety of designs, often in smaller quantities, DTF is a game-changer. The ability to combine multiple images on a single transfer sheet makes it exceptionally economical.

Our Auto-build gang sheet builder was designed specifically for this purpose. It automatically arranges your designs to maximize every inch of the film, making sure every order is as cost-effective as possible. This approach cuts down on waste and makes even one-off custom jobs profitable.

Understanding the Core Printing Technologies

To pick the right transfer, you need to know the "how" behind each method. Both screen print transfers and Direct-to-Film (DTF) transfers create professional, durable graphics, but they get there in completely different ways. Each one offers specific advantages depending on what the job demands.

This difference in process dictates everything from color options to cost. One is an analog craft perfected over decades, while the other is a digital powerhouse built for today's on-demand world.

The Classic Screen Print Transfer Method

Making a screen print transfer is a hands-on process pulled straight from traditional screen printing. The easiest way to think about it is creating a very precise stencil for every single color in your design.

The process works by pushing a thick, durable plastisol ink through a fine mesh screen onto special release paper.

- Screen Creation: A separate screen has to be prepped for each color. An emulsion is coated onto the screen and exposed to light, hardening everywhere except where your design is, which creates the stencil.

- Ink Application: A squeegee forces the ink through the open parts of the screen, laying down one color at a time onto the release paper.

- Layering Colors: For designs with multiple colors, this is repeated layer by layer. Each color needs its own screen and its own pass with the squeegee.

- Curing: The ink is then partially cured on the paper. This creates a stable transfer that can be stored and then applied later with a heat press.

This method is incredibly efficient for large batches of the same design. Once the screens are made, printing is fast. However, the setup is labor-intensive, making it costly for jobs with a lot of colors or small quantities.

The Modern DTF Transfer Process

Direct-to-Film, or DTF, is a completely digital approach that does away with screens entirely. It works a lot like a specialized office printer, but instead of printing on paper, it prints directly onto a transparent film.

This modern method is built for detail, speed, and versatility, which is why it's taken over the market so quickly. In fact, the DTF transfer market is projected to grow at a massive 12% compound annual growth rate (CAGR) through 2026. It's outpacing traditional methods because it’s a perfect match for e-commerce and small-batch custom jobs. You can read more on why this trend is dominating the custom apparel industry.

The real game-changer with DTF is its ability to print any design—no matter how complex or how many colors it has—in a single pass. This completely removes the color-by-color setup that defines screen printing.

The DTF workflow is simple and highly automated:

- Digital Printing: The design is printed directly onto a special PET film with water-based pigment inks. A white ink layer is printed last to act as a base, making sure colors pop on any color fabric.

- Adhesive Application: While the ink is still wet, a fine thermoplastic adhesive powder is spread evenly across the design.

- Curing: The film is sent through a curing oven. The heat melts the powder and bonds it to the ink, creating a single, durable transfer ready for pressing.

The final product is a flexible, ready-to-press transfer that can handle everything from photorealistic images and fine lines to unlimited colors. This efficiency is exactly why tools like our Auto-build gang sheet builder are so powerful—they let you pack dozens of unique, full-color designs onto one sheet, making the process incredibly cost-effective at any order size.

Head-to-Head Comparison: Performance and Quality Metrics

When you get past the production workflow, the real test of any transfer begins. This is where performance and quality metrics—like color vibrancy, the feel on the fabric, and long-term durability—really show you what you're working with. These are the things that define the final product's appeal and longevity.

Both traditional screen print transfers and modern DTF transfers can produce professional, sellable results. But they don't get there the same way, and they definitely excel in different areas. Knowing those differences is key to picking the right one for the job.

Let's put both methods to the test, breaking down their performance across the metrics that truly matter to your customers and your brand's reputation.

Performance Snapshot: Screen Print vs. DTF Transfers

To give you a quick, at-a-glance comparison, here's how these two transfer types stack up across the most important performance attributes.

| Attribute | Screen Print Transfers | DTF Transfers |

|---|---|---|

| Color & Detail | Bold, opaque spot colors. Limited gradients. | Unlimited colors, photorealistic detail, fine lines. |

| Fabric Feel ("Hand") | Thicker, classic plastisol feel. Sits on the fabric. | Very soft, lightweight, and flexible. Part of the fabric. |

| Durability | Legendary. Excellent abrasion resistance. 50-100+ washes. | Excellent. Rated for 100+ wash cycles. Resists cracking. |

| Versatility | Best on cotton & poly/cotton. Special inks needed for others. | Extremely versatile. Works on cotton, poly, blends, nylon & more. |

While this table provides a high-level overview, the real value is in understanding why they perform differently and when to choose one over the other. Let's dive deeper.

Color Vibrancy and Detail

The most immediate difference you'll see is how each technology handles color and fine detail. Screen print transfers are legendary for producing incredibly bold, opaque, and punchy spot colors. Because the plastisol ink is laid down thick, a simple one-color design on a dark shirt will be exceptionally vibrant.

But that's also its main limitation—it's built for solid colors. Gradients, shading, and photorealistic images are either impossible or require complex halftone dot patterns, which can break the smoothness of a design. Every new color adds another screen, more setup, and more cost.

DTF, on the other hand, was born for unlimited color and intricate detail. Since it’s a fully digital process, it can reproduce millions of colors, smooth gradients, and complex patterns with photographic precision. This makes it the undisputed winner for any design that goes beyond simple spot colors. The white ink underbase ensures that even the most complex, full-color designs stay vibrant on any fabric color.

Fabric Feel and Hand

How a design feels on a shirt—what we call its "hand"—is a massive factor in perceived quality. Traditional screen print transfers deliver that classic, slightly thicker plastisol feel. While modern inks are far softer than the old-school stuff, they still create a distinct layer on top of the fabric that you can definitely feel.

For many, this creates a durable, substantial print that’s associated with classic branded apparel. It's a familiar and trusted texture.

DTF transfers offer a totally different experience. The inks and adhesive powder bond to create a much thinner, more flexible layer that almost melts into the fabric's fibers. The result is a soft, lightweight print that stretches with the garment without cracking. This soft hand is almost always preferred for fashion apparel, performance wear, and any garment where comfort is the top priority.

The key differentiator here is integration versus application. DTF feels like part of the fabric, while a screen print transfer feels like a durable graphic applied on top of it.

Durability and Wash Testing

Durability has long been the calling card of screen printing. Plastisol ink is incredibly tough, creating a chemical and physical bond with cotton fibers that can withstand dozens, if not hundreds, of wash cycles without fading or cracking. For workwear, team uniforms, and other high-use gear, this legendary resilience is a major selling point.

For years, digital print methods couldn't even come close. But modern DTF technology has closed that gap in a big way. High-quality DTF transfers, like the ones we produce at Lion DTF, are engineered with advanced adhesives and flexible inks that are lab-tested to endure 100+ wash cycles. They resist cracking and fading, maintaining their vibrancy far longer than any older digital method could.

For a deeper dive, you can learn more about how long DTF transfers last and see the data for yourself. While a perfectly cured screen print might still have a slight edge in pure abrasion resistance, the practical, real-world durability of premium DTF is now on par for virtually all standard apparel.

Material Versatility

A transfer's true value also hinges on how many different materials you can press it onto. This is one area where DTF has a clear and decisive advantage.

Screen print transfers are really designed for cotton and cotton/poly blends. While special formulations exist for other fabrics, their effectiveness can vary, and they often require different temperatures and pressing times.

DTF, however, is the swiss army knife of transfers. Its unique adhesive powder allows it to bond to a huge range of materials with excellent, consistent results, including:

- 100% Cotton

- 100% Polyester

- Cotton/Poly Blends (50/50, tri-blends, CVC)

- Nylon and Spandex

- Even hard surfaces like wood and canvas

This flexibility makes DTF an all-in-one solution for shops that want to decorate everything from standard tees to performance wear and promo items without juggling different transfer types. For any operation that values efficiency, being able to stock one type of transfer for multiple jobs is a huge operational win.

Analyzing the Financial and Operational Differences

It's not just about the final look and feel of a print. The money and workflow behind each transfer method will make or break your shop's profitability. You need to get a handle on the cost-per-print, setup demands, and production speed to pick the right tech for your business. Honestly, choosing between traditional screen print transfers and modern DTF can be the difference between a profitable job and a losing one.

One of the biggest hurdles separating the two is the upfront setup. Screen printing is an old-school analog process. It requires physical screens for every single color in a design, which means higher initial costs and a lot more labor before you've even printed the first transfer. This makes it a tough sell for small, multi-color orders.

The Cost-Per-Print Breakdown

With screen print transfers, the whole financial model is built around volume. The setup costs—burning screens, creating films, and wrestling them into alignment for multi-color jobs—are fixed. It doesn't matter if you print one transfer or one thousand; that initial investment is the same.

This reality creates a clear tipping point. For big orders of a single design (think 50-100+ pieces), that setup cost gets spread so thin across all the units that the cost-per-print becomes incredibly low. But for a small run of just 10 shirts? Those exact same setup fees make the per-unit cost sky-high.

DTF printing completely flips this model on its head. It’s a digital process, so there are no screens and no setup fees. The cost to print the first transfer is the same as the cost to print the hundredth. This makes DTF the undisputed champ for small orders, one-off custom jobs, and designs with a ton of colors—scenarios where screen printing would be way too expensive to even consider.

Maximizing Profitability with DTF Gang Sheets

The real financial magic of DTF is unlocked with gang sheets. This is where you print multiple different designs on one single large sheet of film. This trick dramatically slashes the cost per design by using every square inch of material. Instead of paying for each transfer individually, you just pay for the sheet and cram it full of as many logos, graphics, or images as you can fit.

This is exactly where our Auto-build gang sheet builder becomes a critical tool for your bottom line. It gets rid of all the guesswork and tedious manual arranging by automatically organizing your designs onto the sheet for perfect spacing and almost zero waste. This process guarantees you get the absolute lowest cost per print, making even small, diverse orders incredibly profitable and simple to manage.

By grouping designs for different clients or jobs onto one sheet, you can achieve a per-print cost that rivals high-volume screen printing, but without any of the minimum order constraints. This is a fundamental operational advantage for small businesses and e-commerce stores.

Turnaround Times and Workflow Complexity

From an operational standpoint, the differences are just as stark. The screen print transfer workflow is loaded with physical steps: setting up, printing each color layer by layer, and then cleaning and managing all those screens. It adds time, complexity, and a much higher chance of error, especially on complicated jobs. A typical turnaround from a provider can be anywhere from several days to over a week, depending on how backed up they are.

In contrast, the DTF workflow is simple and lightning-fast. You send a print-ready file straight to the printer, and the entire full-color design comes out in a single pass. This dramatically cuts down production time. At Lion DTF, we can have orders ready to ship in as little as 1-2 business days, with options for same-day pickup, because the process is so direct. For businesses that need to get orders out the door fast, this speed is a game-changer.

The accessibility of these methods has fueled major growth in the decorated apparel world, where small and mid-size shops are the norm. In fact, a solid 30% of businesses in this space report annual sales under $1 million, which shows just how approachable technologies like screen print transfers are for new entrepreneurs. You can find more insights on this growing market by reading about the custom screen printing industry. This ongoing demand really drives home the importance of choosing a production method that truly fits your business's scale and goals.

Real-World Scenarios: When to Choose Each Method

Theory is great, but knowing when to apply it is what really separates the pros. It's one thing to read a pro/con list; it's another to stand in front of a real job and confidently pick the right transfer technology to get the best results—and the best return on your investment.

So, let's move past the specs and get into some common, real-world situations. This is where you'll see exactly when to lean on traditional screen print transfers and when to unleash the power of modern DTF.

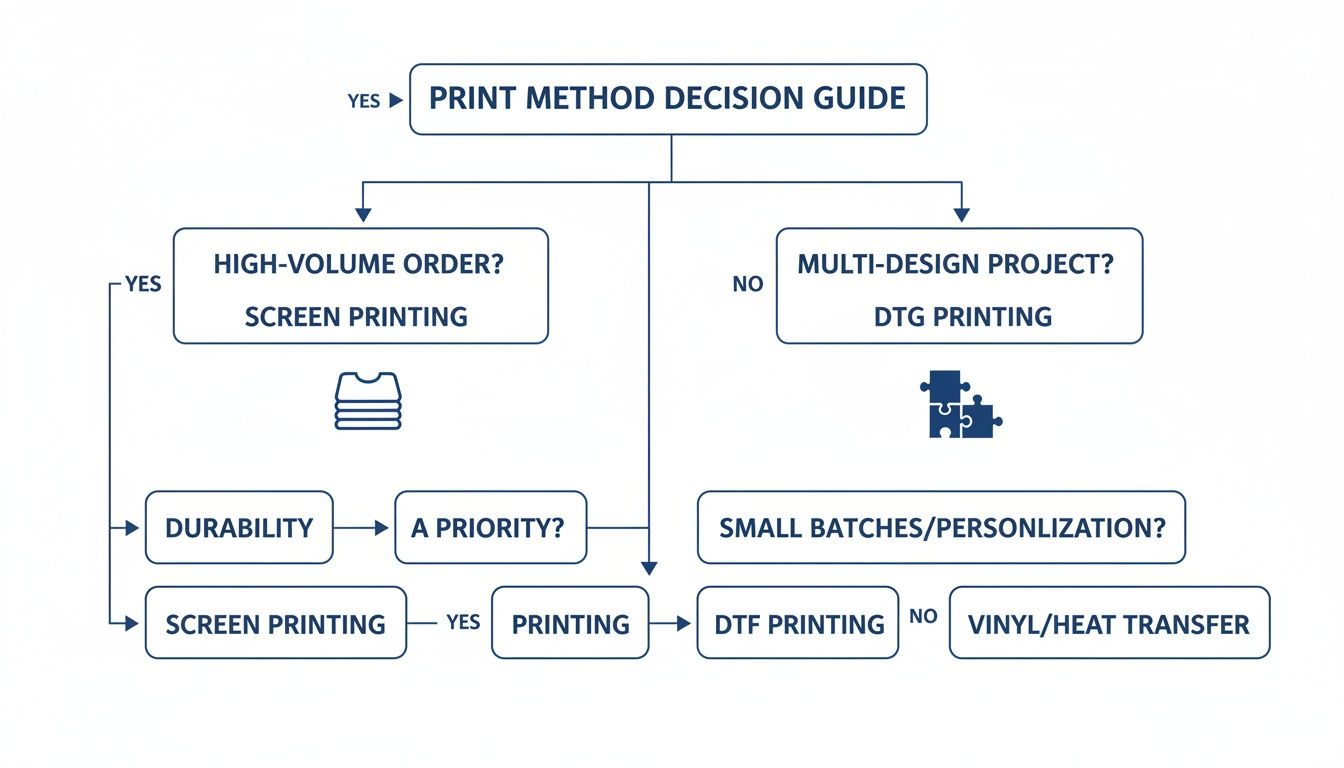

To make it even clearer, this flowchart breaks down the decision-making process based on what matters most for any given job.

As you can see, the path usually splits between high-volume jobs with a single design and smaller, more varied orders. That’s your first clue for picking the right method.

When Screen Print Transfers Are the Clear Winner

Screen printing's entire financial model is built on volume. The setup costs are real—you have to create physical screens—but those costs get spread so thin across a big order that they practically disappear. This makes it the undisputed king for bulk jobs with simpler graphics.

You'll see it shine in scenarios like these:

- Corporate Events and Giveaways: That order for 500 T-shirts with the same one-color company logo for the annual picnic? This is a perfect screen print job. The per-shirt cost will be far lower than DTF, stretching your budget without sacrificing quality.

- Brand Merchandise for a Clothing Line: Your brand's main collection features a bold, two-color logo on hoodies. Ordering 200+ transfers at once makes screen printing the most economical way to keep your core products stocked.

- Annual Charity Runs or Fun Runs: An event organizer needs 1,000 shirts printed with a list of single-color sponsor logos on the back. At this scale, screen printing is really the only game in town.

In every case, the math is simple: high quantity and low design complexity. This is the sweet spot where the classic durability and cost-effectiveness of screen print transfers make them the best tool for the job.

When to Choose DTF Transfers Every Time

DTF picks up right where screen printing leaves off. It absolutely thrives on complexity, variety, and low-quantity orders. Because it's a completely digital process with zero setup, DTF is incredibly agile and fits perfectly with the demands of modern apparel decoration.

DTF is the no-brainer choice in these situations:

- Etsy and E-commerce Shops: Your online store is filled with dozens of different T-shirts, each featuring a unique, full-color design with gradients and photographic detail. DTF lets you print every single one on demand—even just one at a time—with no setup fees eating into your profit.

- Custom Team Jerseys: A local sports team needs 20 jerseys. They all have the same full-color team logo on the front, but every single one needs a different player name and number on the back. DTF handles this kind of personalization effortlessly.

- One-Off Personal Projects: You just want to create one highly detailed, multi-color T-shirt for a birthday gift. DTF makes this not only possible but also affordable.

The real takeaway here is that DTF is built for variability. When every shirt needs to be a little different, or when you’re managing tons of designs in small batches, DTF is hands-down the way to go. It's exactly why we built our Auto-build gang sheet builder—to make managing all that variety ridiculously easy and cost-effective.

Getting Your Custom DTF Transfer Order Just Right

Ready to get your designs off the screen and onto a press-ready transfer? Ordering with us is simple, quick, and designed to get you the most bang for your buck. We've built our process to take the guesswork out of it, making sure your digital file becomes a perfect, vibrant print.

This quick guide will walk you through the essential steps, from prepping your art to using our powerful ordering tools, so you can place your order with total confidence.

Prepping Your Artwork for Flawless Prints

The quality of your final transfer all starts with the quality of your file. Before you upload anything, taking a minute to prepare your artwork correctly is the single most important thing you can do. It prevents printing headaches and ensures your design looks exactly how you pictured it.

Here’s what your file needs:

- High Resolution: Your artwork should be at least 300 DPI (dots per inch). This is non-negotiable for sharp, crisp prints that are free of any blurriness or pixelation.

- Transparent Background: Make sure the file has a transparent background. File types like PNG, PDF, TIF, and AI are perfect for this because they preserve that transparency.

- Correct Sizing: Size your artwork to the exact dimensions you want it to print. What you see is what you get—we print the file as it's provided.

Nailing these details upfront is the fastest way to a smooth order and a perfect final product.

Using Our Auto-Build Gang Sheet Builder

The smartest way to order custom DTF transfers is by creating a gang sheet, which lets you fit multiple designs onto one sheet of film. Our Auto-build gang sheet builder makes this ridiculously easy and efficient, maximizing value and cutting down on waste.

Our builder is a game-changer for anyone looking to save money. It automatically nests your designs to fit as many as possible onto your sheet, instantly showing you the savings. You get the most out of every single inch of film.

Here’s how simple it is to use:

- Pick Your Sheet Size: Start by selecting the gang sheet dimensions that work for your project, from small sheets to massive rolls.

- Upload Your Designs: Just drag and drop all your print-ready files right into the builder. It handles multiple files at once.

- Let It Do the Work: The builder automatically arranges and rotates your images for the tightest fit. You can still nudge things around manually if you need to.

- See What You’re Getting: The tool confirms exactly how many of your designs fit, so there are no surprises. This is a great trick for combining jobs for different clients into a single, cost-effective order. To get even more out of your layout, check out our guide on creating effective DTF gang sheets.

Finalizing Your Order

Once your gang sheet is ready to go, checking out takes just a few clicks. We pride ourselves on fast turnarounds, with most orders shipping out in just 1-2 business days. If you're in a real pinch, we also offer same-day pickup and next-day air shipping options. We'll make sure you get your top-quality transfers exactly when you need them.

Got Questions? We’ve Got Answers.

Jumping into the world of custom apparel always brings up a few questions, especially when you're deciding between different transfer types. Let’s clear up some of the most common things we get asked so you can move forward with total confidence.

Can I Really Use a Home Iron for DTF Transfers?

Technically, yes, but we strongly recommend a heat press for any serious project. While you can apply a DTF transfer with a home iron, it’s a tricky process. You have to apply perfectly even, firm pressure and maintain a consistent temperature, which is tough to do with an iron's spotty heat plate.

For personal, one-off projects, it might work with some patience. For any business purpose, though, a heat press isn't just a suggestion—it's essential for professional, lasting results.

What Are the Go-To Heat Press Settings?

The perfect settings always depend on your fabric. For the classics—cotton and cotton/poly blends—we find that 270-280°F with medium pressure for 10 seconds is the sweet spot.

If you’re working with polyester or other synthetics, you’ll want to dial back the heat to avoid scorching the material. When in doubt, always press a small test piece first.

A classic mistake is cranking the pressure up too high. It can cause the adhesive to ooze out from the edges, leading to a messy, poor-quality press. Stick with medium pressure and only adjust if you absolutely have to.

Is There a Minimum Order for Custom Transfers?

Nope. Not here. One of the best things about our DTF transfer service is that there are no minimum order quantities. Period.

Whether you need a single transfer for a prototype or thousands for a full production run, we’re set up to handle it. This makes it completely risk-free to test out new designs or handle small, custom jobs.

To get the most bang for your buck on smaller orders, our Auto-build gang sheet builder is your best friend. It lets you pack multiple designs onto a single sheet, which drastically cuts down on waste and lowers your cost per print. You can get pricing that feels like a bulk screen print transfer order without having to commit to the volume.

Ready to create some seriously impressive custom apparel? At Lion DTF, we deliver vibrant, top-quality DTF transfers that are ready to press and built to last. Start building your custom gang sheet today!