UV DTF, or Ultra Violet Direct to Film, is a cutting-edge printing technology that has revolutionized the way we transfer images onto various surfaces. This method combines the best aspects of UV printing and DTF printing to offer unparalleled versatility, durability, and quality. But what exactly is UV DTF, and how does it work?

Understanding the Basics

UV DTF printing involves using ultraviolet (UV) light to cure or harden specially formulated inks that are directly applied to a film. The film, which acts as a medium, holds the image until it is ready to be transferred onto the desired substrate. This method stands out due to its ability to produce vibrant, high-resolution images that adhere well to a wide range of materials, including textiles, glass, ceramics, metals, and plastics.

The Process of UV DTF

Design Creation: The process begins with the creation of the digital design. This can be done using graphic design software where the image or text is prepared for printing.

Printing on Film: The design is printed onto a special PET (polyethylene terephthalate) film using UV inks. The UV light cures the ink instantly, resulting in a dry and durable print that doesn't smudge or fade.

Adhesive Application: After printing, an adhesive layer is applied to the film. This adhesive helps the image transfer smoothly from the film to the substrate.

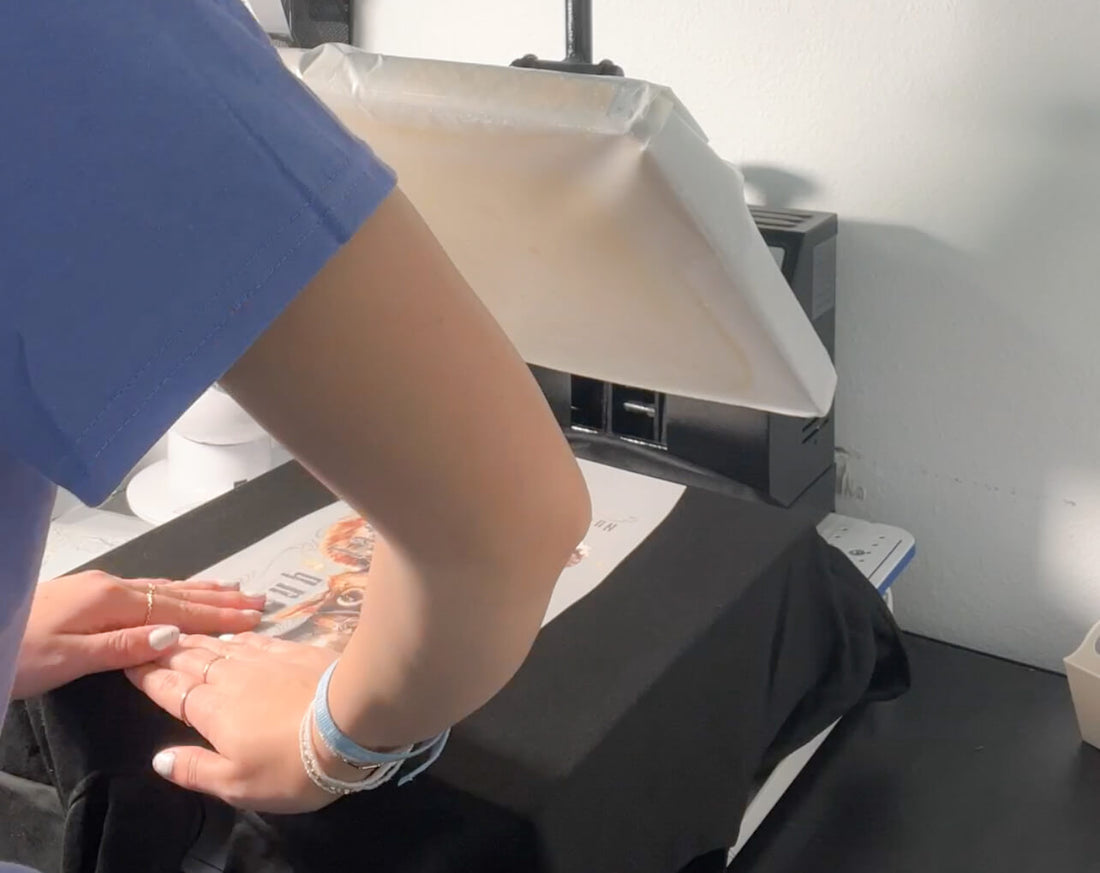

Image Transfer: The printed film is then pressed onto the target surface. Using heat and pressure, the image is transferred from the film to the material, adhering firmly and permanently.

Advantages of UV DTF

Durability: UV DTF prints are highly resistant to wear and tear, including scratches, fading, and exposure to harsh conditions.

Versatility: This method can be used on a variety of surfaces, making it ideal for customized products, promotional items, and industrial applications.

High Quality: The use of UV curing ensures that the prints are vibrant, sharp, and highly detailed.

Efficiency: The process is relatively quick and can be easily scaled for large production runs or customized one-off items.

Applications

UV DTF is widely used in several industries due to its versatility. In fashion, it's used for creating customized apparel and accessories. In home décor, it helps in personalizing items like mugs, plates, and tiles. The technology is also popular in the automotive industry for creating decals and in electronics for branding on devices.

Conclusion

UV DTF printing is a game-changer in the printing industry, offering a unique combination of durability, quality, and versatility. Whether you're a business looking to create high-quality promotional items or a hobbyist interested in DIY projects, UV DTF provides an efficient and reliable solution for your printing needs.