If you've ever wanted to create a custom t-shirt with a complex, multi-color design, you know the old options were a pain. Screen printing meant messy inks, tons of setup, and high costs for small runs. Heat transfer vinyl (HTV) forced you into the tedious job of cutting and weeding, which is a total nightmare for anything intricate.

DTF ready to press transfers are a game-changer. Think of them as pro-level, permanent decals for fabric. They arrive as finished designs printed on a special film, ready for you to apply with just a heat press. It’s that simple. This makes professional printing truly accessible, whether you're a hobbyist or a growing apparel brand.

What Are DTF Transfers and Why Use Them?

DTF, which stands for Direct-to-Film, basically builds a bridge between the best qualities of other print methods. The concept is straightforward: a design is digitally printed onto a clear film, backed with a special white adhesive powder, and then cured. What you get is a vibrant, durable, ready-to-press transfer that you can apply to almost any fabric in just a few seconds.

The advantages of DTF really stand out when you compare it to the old ways. It skips the steep learning curve and heavy investment that used to keep people out of the custom apparel game.

We put together a quick table to show you just how different the experience is.

DTF Transfers vs Traditional Methods

| Feature | DTF Ready to Press Transfers | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Color Complexity | Unlimited colors and gradients in one press | One screen per color, complex setups | One layer per color, complex layering |

| Setup Time | None. Just press and go. | High setup time, screen prep, ink mixing | Time-consuming cutting and weeding |

| Small Batches | Very cost-effective, even for one-offs | Not practical due to high setup costs | Feasible but labor-intensive for each item |

| Fabric Versatility | Works on cotton, poly, blends, and more | Best on cotton, specific inks for others | Limited by fabric type and adhesive |

| Detail & Gradients | Handles fine lines and photorealism easily | Limited detail, halftones are complex | Very difficult with intricate designs |

As you can see, DTF just simplifies everything, letting you focus on your designs instead of fighting with the process.

The True Advantage of Ready to Press

The "ready to press" part is where the magic happens for creators and businesses. You don't need to buy expensive printers, powders, or curing ovens. You just get the finished transfers delivered to your door, ready to go. All you need is a heat press. This dramatically lowers the barrier to entry for producing retail-quality gear.

This opens up a ton of possibilities for all kinds of people:

- Small Businesses: You can launch a clothing line or create branded merch without the huge overhead of a print shop.

- Etsy Sellers: Offer complex, full-color designs on demand, blowing past the creative limits of vinyl.

- Hobbyists: Easily turn your cool ideas into professional-looking apparel for gifts, events, or just for fun.

Efficiency and Cost Effectiveness Combined

Beyond just being easy, DTF ready to press transfers are also incredibly cost-effective, especially if you order smart. Instead of printing designs one by one, you can group a bunch of them onto a single large sheet, called a gang sheet. This maximizes every inch of the film and slashes your cost per design. For ultimate ease of use, an Auto-build gang sheet builder can arrange your designs perfectly, ensuring you get the most value with zero hassle.

This combination of simplicity and affordability is a massive win. To see a more detailed breakdown, our guide on Direct-to-Film vs. Direct-to-Garment printing dives even deeper.

DTF technology levels the playing field, allowing small-scale creators to produce apparel with the same quality, vibrancy, and durability as large-scale operations. It removes the technical hurdles, putting the focus back on creativity and design.

Getting Perfect Results When Applying Your DTF Transfers

Applying a DTF ready to press transfer seems simple, but getting that flawless, professional finish everyone wants comes down to a simple formula: Time + Temperature + Pressure. If you can dial in these three things, your designs won't just look amazing—they'll fuse with the fabric and last wash after wash.

It's a lot like baking a cake. You need the oven at the right temperature, for the right amount of time, with the right ingredients. Get one of those wrong, and you’re not going to love the result.

The great thing about DTF is how well it works on different materials. Your specific heat press and even the room you're in can cause slight variations, but there are solid starting points for the most common fabrics you'll be printing on. These settings are what activate the adhesive, letting it melt right into the garment's fibers.

Heat Press Settings for Popular Fabrics

Before you even think about pressing, you have to know what you're working with. Cotton, polyester, and blends all react differently to heat. Using the wrong settings can lead to a transfer that peels right off or, even worse, a scorched shirt.

Here’s a quick guide to get you started on the right track:

- 100% Cotton: This is the easiest fabric to work with. Go for a temperature of 280°F and press for 10 seconds with medium-to-firm pressure. Cotton fibers grab onto that DTF adhesive, making for a super strong bond.

- 100% Polyester: Polyester is a bit more sensitive. Too much heat can scorch it or cause dye migration (where the fabric color bleeds into your white ink). Drop the temp to 240-250°F and press for only 7-10 seconds.

- Cotton/Poly Blends (e.g., 50/50): For blends, you need to find a happy medium. A temperature of 260-270°F for 10 seconds is usually the sweet spot, keeping both the cotton and polyester fibers happy.

Pro Tip: If you're ever unsure about a fabric, always do a test press on a small, hidden spot. This one simple step can save you from ruining a whole garment and helps you dial in the exact settings for your press.

The Step-by-Step Pressing Workflow

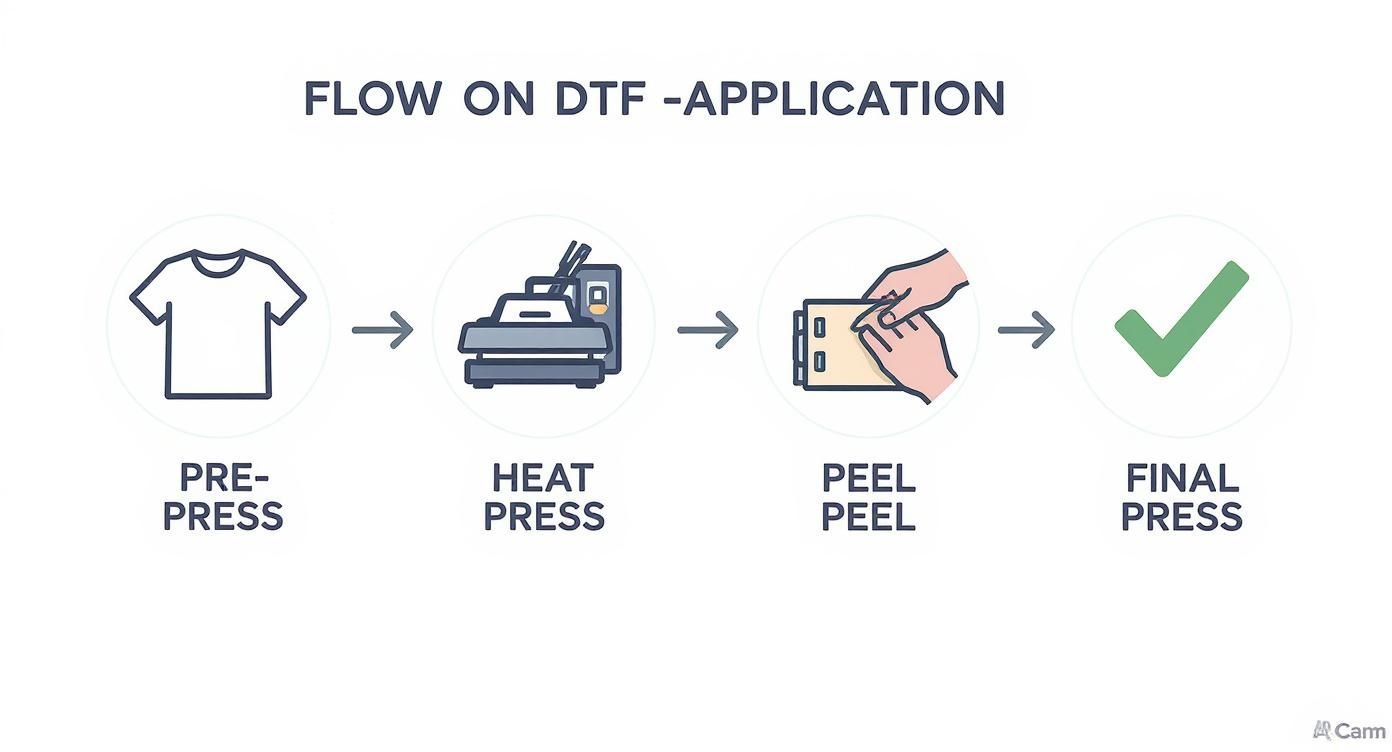

Once you've got your settings figured out, it's time to press. This four-step process is designed to prevent common problems, like moisture messing up the adhesion, and ensures the transfer melts into the fabric for that soft, retail-ready feel.

- The Pre-Press: Put your garment on the heat press and give it a quick press for 5-7 seconds. This is a non-negotiable step. It gets rid of any moisture hiding in the fabric and flattens out wrinkles, giving you a perfect surface for your transfer.

- Placement and First Press: Lay your DTF transfer on the garment, design side up. When you've got it exactly where you want it, press it using the settings you picked out for your specific fabric.

-

The Instant Hot Peel: As soon as the timer dings, instantly peel the transfer by grabbing a corner and peel the film back at a low slanted angle. Waiting to peel it is the #1 mistake people make, and it can cause the design to lift or even tear.

- Cold Peel Option: This option is recommended for extra fine artwork and on certain fabrics. Then, let it cool down completely, all the way to room temperature. Once it's cool to the touch, grab a corner and peel the film back slowly, smoothly, and at a low slanted angle. Don't rip it off like a band-aid. A slow, deliberate peel is what leaves your crisp, vibrant design perfectly stuck to the fabric.

- The Final Press: For a professional matte finish that locks the design into the fibers, do one last press. Cover the design with a Teflon sheet or parchment paper and press it again for 5-7 seconds. This final touch makes a huge difference in wash durability and gives the print that coveted soft-hand feel.

Following these steps turns pressing from a guessing game into a reliable process. It's how you guarantee every single garment you make with DTF ready to press transfers has the quality to be worn and washed over and over again.

Creating Cost-Effective Designs with a Gang Sheet Builder

One of the biggest money-saving secrets in DTF ready to press transfers is learning how to maximize every square inch of film. The key to this is the gang sheet—a single large sheet where you print a bunch of different designs all at once.

Think of it like baking cookies. You wouldn't put just one cookie on a giant baking sheet, right? You’d fill it up to save time and oven space. A gang sheet does the same thing for your designs. Instead of paying for each transfer one by one, you pay for the whole sheet. By packing it with logos, sleeve prints, neck tags, and full-sized graphics, the cost per design drops dramatically.

What Makes a Gang Sheet So Efficient?

The magic of a gang sheet is all about eliminating wasted space. Every blank spot on that film is money down the drain. But trying to manually arrange all your designs to fit perfectly can feel like a frustrating game of Tetris, especially if you aren't a graphic design pro.

This is where a good tool comes in. An automated builder can take all your uploaded images and nest them together with perfect precision. It rotates and fits every piece flawlessly, ensuring you get the most bang for your buck by using as much of the film as possible. Our Auto-build gang sheet builder offers this level of ease of use and cost-effectiveness, turning a complex task into a simple upload.

A well-optimized gang sheet isn't just a convenience; it's a core strategy for profitability in the custom apparel business. It empowers you to produce more for less, directly boosting your bottom line with every press.

If you're interested in arranging designs yourself, there are plenty of options. Check out our guide on how to create a DTF gang sheet in Canva to get started. For pure, effortless efficiency, though, nothing beats an automated solution.

Meet the Auto-Build Gang Sheet Builder

We wanted to make this process dead simple, so we created our own Auto-build gang sheet builder. It’s a user-friendly tool designed to do all the heavy lifting for you, saving you both time and cash.

The process couldn't be easier. Just upload all the designs you need, no matter their size or shape. Our software takes it from there, automatically arranging everything to pack the sheet as tightly as possible. What could take you ages to do by hand, it does in seconds.

Whether your designs come from a gang sheet or are printed individually, the application process is always the same simple, four-step method.

From pre-pressing the shirt to the final press, following these steps ensures you get a professional and durable print every single time.

This level of efficiency is a huge deal in the custom t-shirt world, which is really what’s driving DTF’s popularity. The t-shirt segment makes up about 41 percent of the total revenue for ready-to-press transfers. It's all fueled by the demand for personalized gear and the rise of print-on-demand businesses that need fast, quality results. Since DTF works so well on cotton and blends, it has quickly become the go-to for t-shirt creators.

Exploring Different Types of DTF Transfers

While gang sheets are a game-changer for big jobs, thinking that's all DTF ready to press transfers have to offer is selling them short. Once you get a feel for the different ways you can order and use them, you'll unlock a whole new level of creative freedom for projects of any size. From a single prototype to a massive holiday collection, there’s a DTF solution that fits perfectly.

This kind of flexibility is a huge deal for creators and businesses. You're no longer stuck with high minimums or forced to cram unrelated designs onto one sheet. Now, you can order exactly what you need, right when you need it.

Beyond the Gang Sheet: Single Custom Images

Sometimes, you just need one specific design. This is where ordering single images comes in clutch, especially for one-off projects where a full gang sheet would just be overkill.

- Prototyping: A small brand launching a new tee can grab a single print to test the design on a real garment before committing to a big production run.

- Special Gifts: You can create a truly one-of-a-kind, personalized t-shirt for a birthday or family reunion without getting stuck with extras.

- Etsy Seller Samples: An Etsy seller can press a sample of a new graphic tee to get those perfect, high-quality product photos for their online shop.

Ordering single images gives you the freedom to experiment and bring ideas to life without a huge financial commitment. It’s the perfect way to test the waters with professional quality.

The ability to order single, custom DTF transfers empowers creators to move at the speed of inspiration. It removes the barrier of minimum order quantities, making it possible to test, iterate, and perfect designs with minimal risk and maximum creativity.

Ready-to-Ship Collections

Need trendy, high-quality designs but don't have the time to create them yourself? Pre-made, ready-to-ship collections are your answer. These are curated sets of transfers built around popular themes, holidays, and what's hot right now, ready to head out the door immediately.

This approach is perfect for:

- Seasonal Sales: Quickly stock up on Halloween, Christmas, or patriotic designs to catch those holiday shopping waves.

- Trending Niches: Tap into popular markets like Western, retro, or coffee-themed apparel without spending hours on design work.

- Pop-Up Shops: Easily fill your booth with a diverse range of eye-catching graphics that appeal to just about everyone.

Ready-to-ship collections are a major time-saver, ensuring you always have relevant, in-demand inventory ready to go.

Putting It All Together for Maximum Impact

The real magic happens when you start combining these options. An established brand might use our Auto-build gang sheet builder for its main logo prints to get the best price, order single transfers to test out new slogans, and grab ready-to-ship seasonal designs to keep things fresh. This hybrid approach strikes the perfect balance between efficiency, creativity, and staying on top of market trends.

This adaptability is a huge reason why the DTF market is blowing up. North America is leading the charge, holding a projected 5.5 percent annual growth rate through 2032. This growth is fueled by a strong e-commerce backbone and massive consumer demand for the exact kind of personalized products DTF makes possible. You can learn more about these market trends and their impact on the industry.

How to Wash and Care for Your DTF Garments

You’ve pressed the perfect design, and it looks incredible. Now what? The real test of a great print is how it holds up in the real world, through daily wear and countless laundry cycles.

Proper care is what turns a one-hit-wonder into a long-term favorite tee. The good news is that keeping your DTF garments looking brand new is actually pretty simple. It all comes down to avoiding a few key things: harsh chemicals, high heat, and too much friction.

Your Go-To Laundry Routine

Think of your DTF transfer as a strong, flexible layer bonded right into the fabric. While our transfers are incredibly durable—we’ve tested them for 100+ washes—they aren’t invincible. A little mindfulness in the laundry room goes a long way.

Here’s the simple routine we swear by for maximum durability:

-

Turn Garments Inside Out: This is the easiest and most important step. Before tossing anything in the wash, flip it inside out. This shields the design from rubbing against other clothes, zippers, and buttons, which is the number one cause of wear and tear.

-

Use Cold Water & Mild Detergent: Always wash your DTF apparel in cold water on a gentle cycle. Hot water can soften the transfer's adhesive over time. Stick to a mild detergent and steer clear of bleach and fabric softeners, as they can break down the inks and lead to fading or cracking.

-

Tumble Dry Low or Hang to Dry: High heat is the biggest enemy of a DTF transfer. Just like heat was used to apply the design, too much heat from a dryer can reactivate the adhesive and make it tacky or prone to peeling. Tumble dry on the absolute lowest heat setting, or better yet, just hang the garment up to air dry.

The secret to protecting your DTF transfer is just avoiding the extremes. Skip the hot water, harsh chemicals, and high-heat drying. That’s it. By doing so, you preserve the bond between the ink, adhesive, and fabric, ensuring your design stays as sharp as the day it was pressed.

Why Each Care Step Matters

It’s easier to remember the rules when you know the "why" behind them. High heat in the dryer doesn't just risk peeling; it can make the transfer feel sticky. Harsh chemicals like bleach don't just fade colors—they can literally strip the pigment out of the ink, leaving a vibrant design looking washed out.

By following these simple guidelines, you can give your customers (or yourself) the confidence that their custom gear is built to last. For a quick reference, you can always check out our full guide on pressing and shirt care instructions.

Giving this kind of expert advice shows that your dtf ready to press transfers aren't just a quick novelty—they're made for the long haul, ready to be worn and loved for years.

Understanding the Growth of the DTF Printing Market

If you've noticed dtf ready to press transfers popping up everywhere, it’s not just a coincidence. We're in the middle of a massive shift in the custom apparel world, and this technology is front and center. It's more than a trend—it's the answer to a huge demand for personalization, supercharged by the boom in e-commerce.

For years, making custom gear felt like a compromise. You could get the amazing, multi-color prints of screen printing, but only if you were ready for steep setup fees and big minimum orders. Or, you could go with vinyl for one-off jobs, but that meant dealing with tedious weeding and serious design limits. DTF printing came in and fixed all of that, finally giving small and medium-sized businesses a way to get high-quality results without the old headaches.

The Forces Driving DTF Adoption

So, what created the perfect storm for DTF to take off? A few key things happened all at once. First, the technology itself got better, cheaper, and easier to get. The printers and supplies are no longer just for massive print shops, which lowered the barrier to entry for creators everywhere.

At the same time, what people want has changed. Generic, mass-produced clothing just doesn't cut it anymore. Everyone is looking for unique, personalized items, whether it's branded gear for their business or a one-of-a-kind graphic tee. Marketplaces like Etsy and Shopify have made it possible for anyone to launch a brand from their garage, and DTF is the perfect engine for that model. You can print on demand, with zero need to hold a ton of inventory.

The numbers back this up, big time. The global Direct-to-Film printing market, which includes DTF ready to press transfers, was valued at USD 2.72 billion and is on track to hit USD 3.92 billion by 2030. That’s a steady growth rate of 6 percent a year, proving that DTF isn't just a flash in the pan—it's a smart, forward-thinking technology. You can dig into the numbers yourself and explore the full market analysis and revenue forecast to see what's driving the industry.

By removing the traditional barriers of complexity and cost, DTF technology has democratized professional apparel printing. It allows small businesses to compete directly with larger operations on quality, speed, and creative freedom.

A Cost-Effective and User-Friendly Solution

When you boil it all down, the incredible growth of DTF comes from its killer combination of quality, versatility, and cost. It gives you the vibrant colors and soft feel that customers love, while being incredibly efficient on the production side.

Tools like our Auto-build gang sheet builder take those benefits even further, making it dead simple to squeeze every last bit of value out of your film and slash the cost per design. It’s this blend of quality and efficiency that makes it easier than ever for businesses to scale up profitably, confirming that your move into this technology is the right one.

Got Questions? We’ve Got Answers.

Jumping into dtf ready to press transfers is exciting, but it’s totally normal to have a few questions before you get started. Let's clear up some of the most common ones so you can feel confident and ready to press like a pro from your very first try.

What Fabrics Can I Use DTF Transfers On?

This is hands-down one of the best things about DTF. Its versatility is incredible. While other print methods can be really picky, DTF is the complete opposite and works beautifully on almost anything you can throw at it.

You can press with confidence on:

- 100% Cotton and Ringspun Cotton: The go-to for classic tees and hoodies.

- Polyester: Perfect for performance gear and athletic apparel.

- Cotton/Polyester Blends: Think 50/50s and super-soft tri-blends.

- Canvas and Denim: Awesome for creating custom tote bags, jackets, and aprons.

- Tricky Materials: With the right settings, you can even press on leather, nylon, and rayon.

This massive range means you can expand your product line without juggling a half-dozen different types of transfers. It's a genuine one-and-done solution for custom apparel creators.

Do I Need a Special Heat Press?

Nope, you don't need a special "DTF-only" press. The great news is that just about any standard, quality heat press will get the job done perfectly for dtf ready to press transfers.

What really matters are three things: consistent correct temperature, even pressure and the correct pressing time. As long as your press can hold a steady heat across the entire platen and clamp down firmly, you’re all set to produce durable, professional-looking prints.

How Does a DTF Print Feel Compared to Vinyl?

This is where DTF truly pulls ahead of the pack. We all know that heat transfer vinyl (HTV) can sometimes feel thick, stiff, and like a plastic sticker sitting on top of the fabric. A DTF print couldn't be more different.

When applied correctly, a DTF transfer is incredibly soft, lightweight, and flexible. The ink actually bonds with the fabric fibers during that final press, allowing it to stretch and move with the garment. The result feels much more like a high-end screen print, giving your products that premium, retail-quality feel customers love.

Think of it this way: Vinyl sits on top of the fabric, but a DTF transfer becomes a part of the fabric. That integration is what creates a far superior feel and better durability.

Can I Just Use a Home Iron?

This is a hard no. While it's tempting to try for a quick one-off project, a regular home iron just won't cut it. Irons have hot and cold spots that create wildly uneven heat, and they can't generate the consistent, heavy pressure needed to properly cure the DTF adhesive.

Using an iron will almost guarantee a print that peels, cracks, or washes away after just one or two laundry cycles. For a permanent, professional bond that lasts, a real heat press is an absolute must-have.

Ready to start creating vibrant, durable apparel with total ease? At Lion DTF Transfers, we make bringing your designs to life simple. Use our Auto-build gang sheet builder for maximum value or shop our ready-to-press collections. Experience the industry-leading quality and speed for yourself over at https://liondtf.com.